Three commonly used feed methods for thread machining:

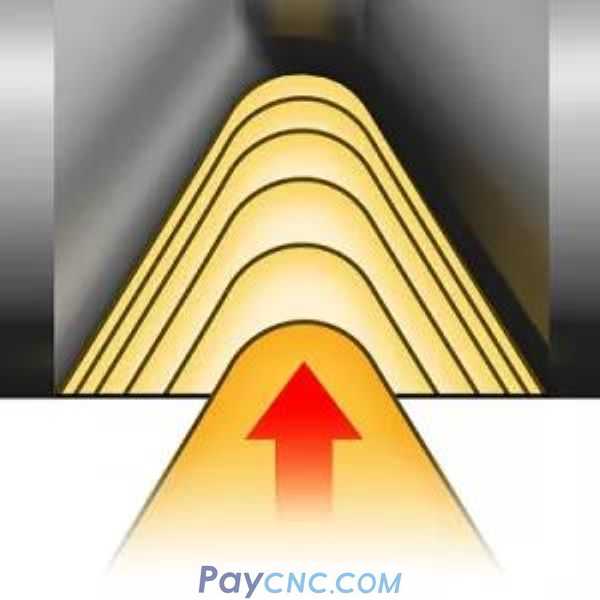

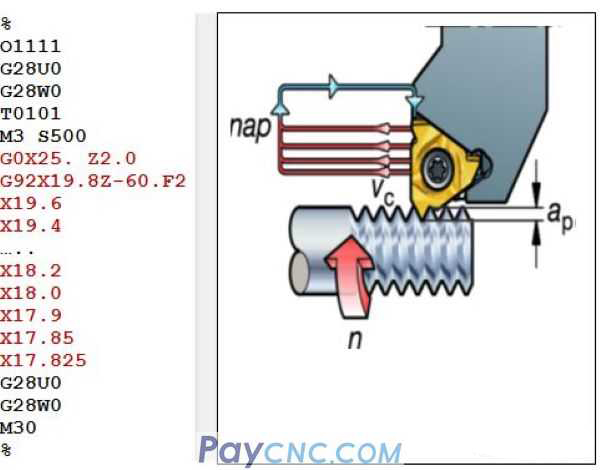

Straight feed

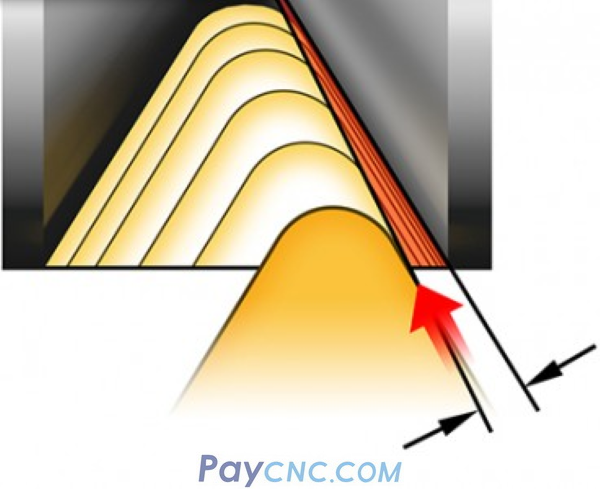

Side feed

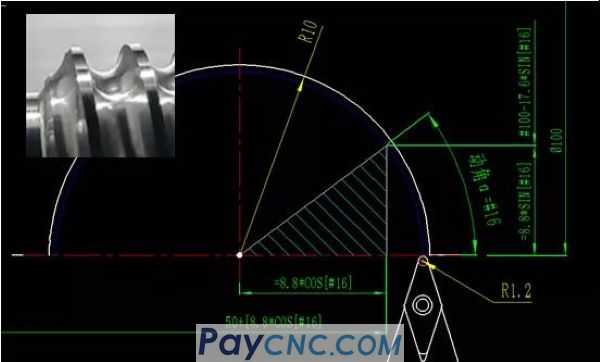

Alternate feed

Different feed processing methods have different effects on tool wear and thread quality.

This cutting method requires the tool profile and thread profile to be exactly the same.

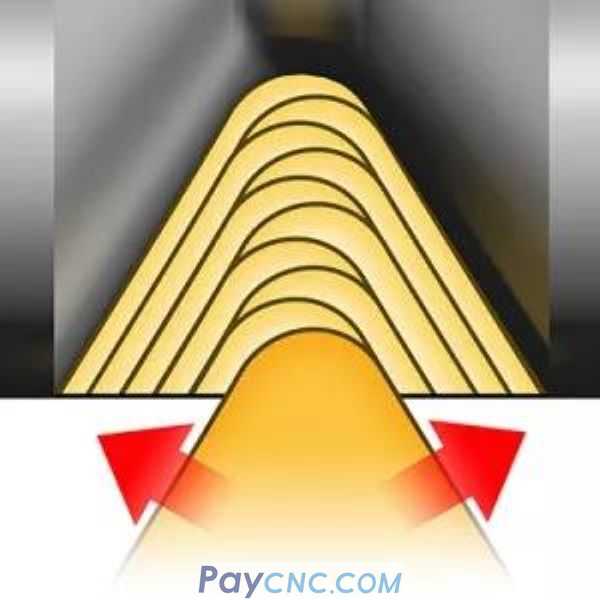

After the thread cutter cuts into the part, the entire cutting edge is stressed.

As the turning tool cuts deeper, the cutting edge of the tool cuts longer.

The longer the cutting length of the cutting edge, the greater the cutting force that the tool and parts bear.

Well, after understanding the characteristics of this way of knife, the solution:

1. In this way, small pitch thread is preferred.

2. When programming, the cutting depth increases with the cutting depth, the longer the cutting length of the tool cutting edge, and the greater the cutting force, so the cutting depth is better to decrease gradually.

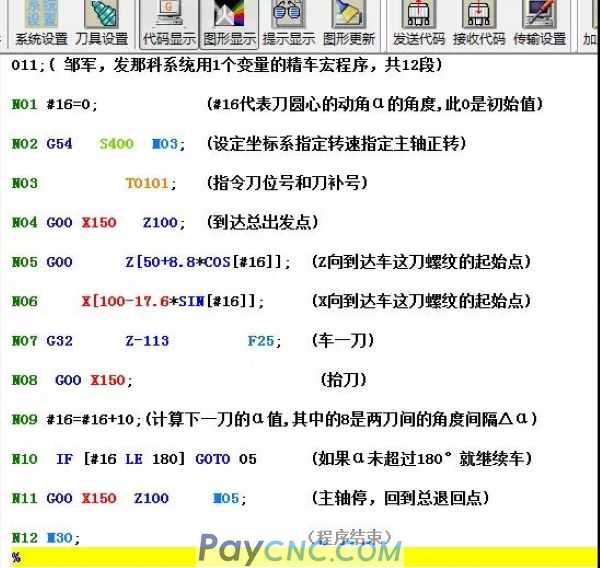

Here is an example, such as processing M20x2 external thread (bottom diameter 17.825)

This cutting method is mainly cut by the cutting edge on one side of the tool.

The tooth profile can be less than or equal to the thread profile. If the selected tool is equal to the thread profile, which is the so-called forming knife, as the cutting becomes deeper, the entire cutting edge of the tool is also stressed.

Therefore, it is recommended to choose the tool to be slightly smaller than the thread angle, so that processing large-pitch threads can reduce the vibration in the cutting process.

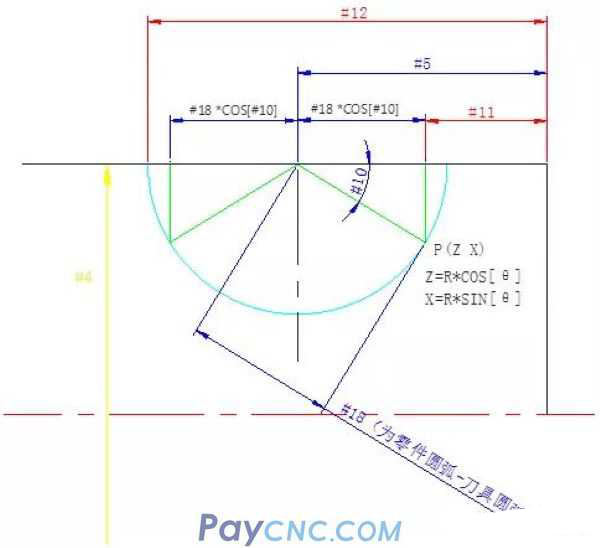

Ok, let me use a macro program to give an example. For example, a 35-degree tool (VCMT160412...

The programming is completed quickly through parameter equations, and the program is relatively simple and will not be repeated.

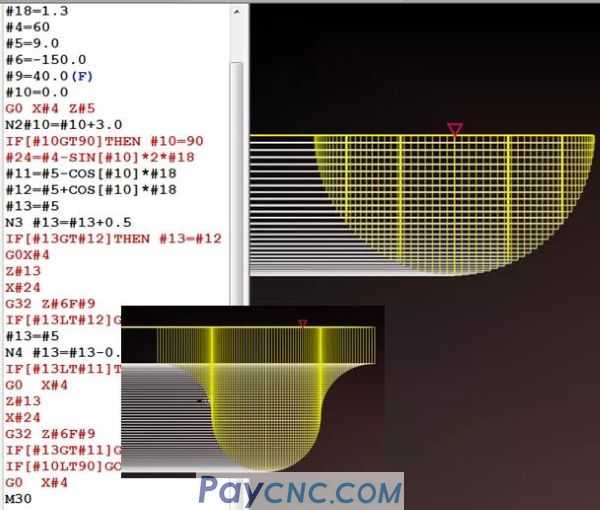

The tool cuts into the workpiece in a left and right alternate feed, gradually expanding the thread alveolar to the specified size.

This cutting is suitable for threads with extremely large pitches, which can significantly reduce vibration during cutting.

requires attention:

The tool tooth profile size should be smaller than the thread profile size, so as to complete the alternate tool borrowing.

Ok, let me use a macro program to give an example, such as the arc thread with a relatively large tooth profile, to complete the alternate turning, and directly use variables instead of the specific size of the part. The diagram is as follows:

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|