The machining center integrates multiple processing functions such as milling, drilling, boring, and thread tapping. A variety of tools are used in the machining process. Therefore, the tool changer is an important part of the machining center, and it is also the part of the machining center with a higher failure rate. , Among them, chaotic knife is one of the faults.

The following is a case of VMC850/GSK25iM-H to analyze the causes and troubleshooting methods of the disordered tool in the machining center

01Fault phenomenon

Random tool refers to the phenomenon that the tool number of the tool change command is inconsistent with the tool seat number in the library. For example: the program specifies M06 T03, and the tool change manipulator grabs the tool of the No. 5 tool holder when changing the tool, it is called the chaotic tool phenomenon.

02Troubleshooting

When the machining center is equipped with a disc type to the library, the phenomenon of chaotic tools occurs during the tool change, generally because the sensor used for counting in the library is under the influence of uncertain factors (voltage shock, dust, iron cutting, moisture, etc.). The counting signal is lost or added to the system during rotation, causing the tool number value in the system data table to be inconsistent with the tool number programmed in the actual tool magazine, resulting in chaotic tool failure

03Troubleshooting

To solve the problem of disorderly tools, first remove all the tools on the tool magazine as shown in Figure 3-1

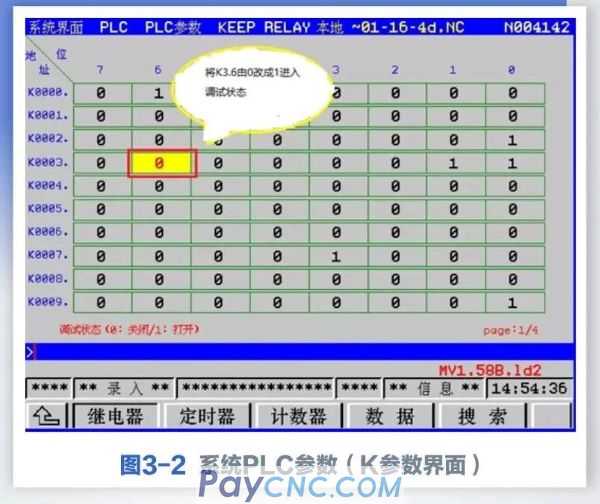

Enter the system plc interface to change the relay parameter K3.6 (tool magazine debugging state) from 0 to 1 and the system enters the tool magazine debugging mode as shown in Figure 3-2

Enter the data table initialization: switch the tool return to reference point mode, press the tool magazine zero key on the machine operation panel, wait for the tool magazine to rotate to the No. 1 tool pocket position, when the indicator light of the tool magazine zero key is on, the plc diagnostic interface X14.1 There will be 0 jumps to 1, as shown in Figure 3-3

The system switches the tool MDI mode, enters and executes the M76 command on the MDI display interface, and the tool data table automatically restores the initial value, as shown in Figure 3-4, Figure 3-5 and Figure 3-6

After the data table parameters are set successfully, the disordered tool fault is removed and the tool can be reinstalled for use

04 Conclusion

Special attention should be paid to the chaotic tool failure when the machining center is equipped with a disc-type tool magazine. Once this failure occurs, it may cause tool collision and machine collision accidents. Therefore, this failure must be repaired and solved in time. Also pay attention to the regular maintenance of the tool magazine, such as formulating a periodic plan to clean and maintain the periphery of the tool magazine, especially the position with sensors, and check the screw tightening of the tool magazine components

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|