GSK988TD User:

I’ve nearly finished the Okuma 5 axis CNC lathe retrofit and only have 2 more task to finish.

I’m having some problems getting the turrets to index properly and not produce errors.

I’ve made a bug in the ladder diagram.

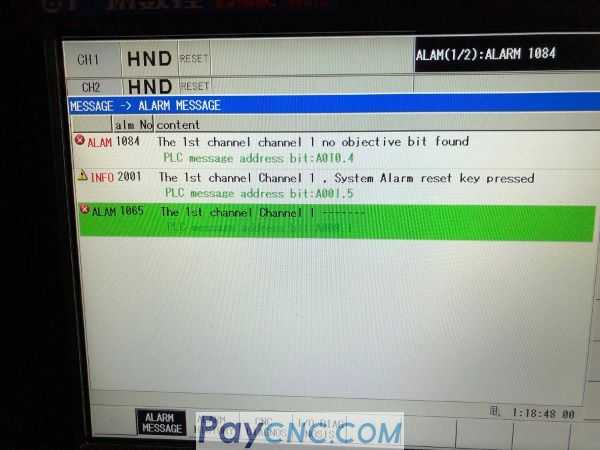

I’ve attached the ladder diagram I’m using and also included the parameter file and a text document outlining what Inputs and outputs are allocated and a picture showing the alarms .

I ended up altering the turret location switch setup which was originally a resolver and have now fitted a couple of Binary code discs (see photo) with micro switches to detect turret position.

When I index the turrets I can see in the ladder diagram the switches being made .

When doing a tool change on the top turret the turret unclamps and rotates to the correct position and clamps , but then produces a couple of alarms (alarm number 1084 and 1065) the turret position number doesn’t update on the panel.

On the bottom turret when a tool change is attempted , the turret unclamps but doesn’t rotate. If you press the reset button the turret clamps but no tool position is shown (only 00) and error 1073 is produced . The inputs and outputs I’m using in the ladder are detailed on pages 7 & 8 of the word document.

Also I have fitted a Renishaw tool setting probe to the machine and have wired it to the G36 and G37 inputs however the machine doesn’t see the probe. The manual says that parameter 6140 bit 7 needs to be set to 0 but my parameter file doesn’t have a 6140 . Is this supposed to be 6240 ? The Renishaw probe interface has the option of using 4 outputs or 1 output for all 4 directions. If you are using 4 separate outputs , you need to have an output from the NC controller to select the output line your using. In my case I have chosen a single output as this is active all the time and doesn’t require an output from the NC and have wired this to both G36 and G37.

CNCmakers Support:

1- Please reset the zero point.

2- Change parameter 1815.4 to 0, then change to 1 again. the zero point setting is done.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|