Dalian 6180X1500 ordinary lathe with GSK980Tdi CNC system hub mold engraving processing application

After the Dalian 6180X1500 ordinary lathe equipped with GSK980TDi system was changed into a CNC special machine, a linear exhaust groove was carved on the wheel mold.

02

solution

According to the customer's parts processing technology to develop transformation plans;

The spindle is equipped with a servo motor drive, and the synchronous wheel is changed to synchronize the spindle indexing rotation, the speed reducer is used to achieve the inertial indexing positioning accuracy, and the disc brake function is increased (the mold size and weight are relatively large);

Install high-speed engraving and milling head on X-axis pallet;

Continuous mass production can be run continuously.

Application effect

Satisfying the customer's requirements for engraving and processing products, greatly reducing the cost of customer equipment input.

C-66 CNC lathe with GSK980TDi CNC system wire mold carving application

01

After the C-66 CNC lathe is equipped with the GSK980TDi system and the power head is installed, it can realize the dual purpose of turning and engraving the electric cable mold on the machine tool.

solution

Continuous mass production can be run continuously.

According to the customer's parts processing technology to develop transformation plans;

Spindle servo motor drive, the traditional ordinary belt drive changes to the synchronous wheel synchronous belt to drive the spindle indexing rotation, increase the disc brake function, the ordinary encoder is changed to a higher linear speed encoder;

Install a power milling head behind the tool holder on the X-axis pallet, adjust the power head transmission gear ratio to achieve 6000 speed;

Application effect

Meet the requirements of customers' engraving and processing products, stable mass production, greatly reducing the cost of customer equipment input.

Application of Shenyang CAK50186 machine tool with GSK 980TDI numerical control system for processing slender shaft parts

01

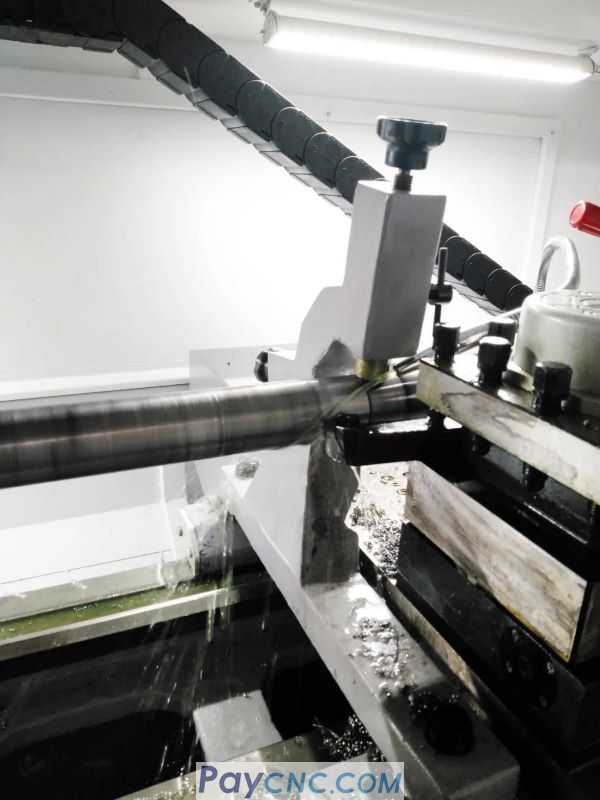

Use Shenyang CAK50186 machine tool with GSK 980TDI system to process a slender shaft with a length of 1.5 meters and a diameter of 50

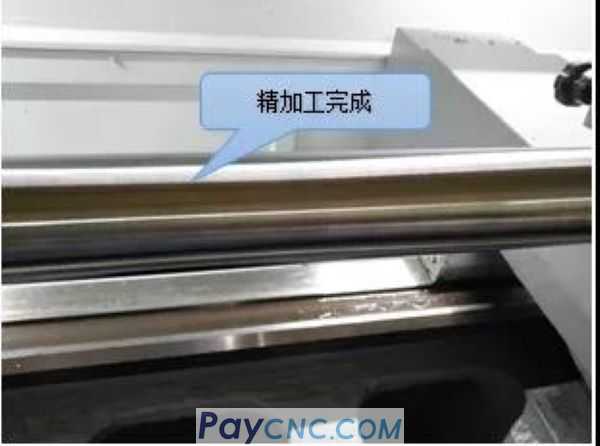

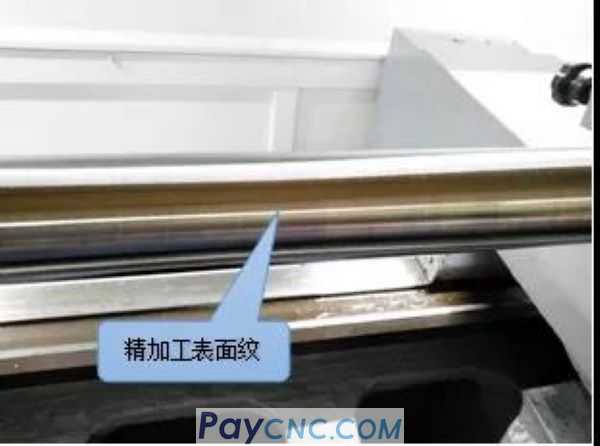

No vibration during processing, the surface texture of the workpiece is clear, the roughness is 3.2, and the straightness is 0.02mm;

Processed and tested according to the drawing size.

solution

Clamping method: adopt one clip and one top + follow knife holder;

Machine tool requirements: machine tool horizontal deviation ≤0.02mm, tailstock and spindle equal height deviation <0.05mm, tail top and workpiece contact surface more than 3mm;

Use high-quality tools to start roughing first and then finish machining to improve efficiency.

Application effect

There is no vibration pattern on the outer circumference of the workpiece, the overall pattern is clear and free of disorder, and the straightness is stable at 0.02mm, which meets the customer's requirements.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|