Diameter Φ Chamfering a Angle θ Tangent function tan θ Sine function sin θ Cosine function cos θ Arc radius R multiplied by number x

Division by sign ÷ first calculate the result in (), then calculate 【】, and then calculate the full expression

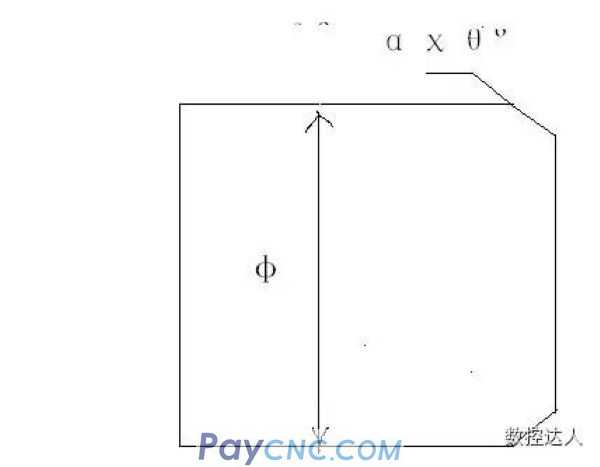

1. The calculation formula of the outer chamfer angle

Example: Φ 30 diameter outer end chamfer 1.5x60°

Program: Go X32 Z2

1. The starting point diameter of chamfering X= Φ-2xaxtanθ° X=30-2x1.5x1.732=24.804 G1 X24.804 Z0 F0.2

2. The starting point length of the chamfering Z=0 where tan60° is found by the math table G1 X30 Z-1.5 F0.15

3. Chamfering point diameter X= Φ; G1 Z-50

4. Length of chamfering point Z= -a. . . . . .

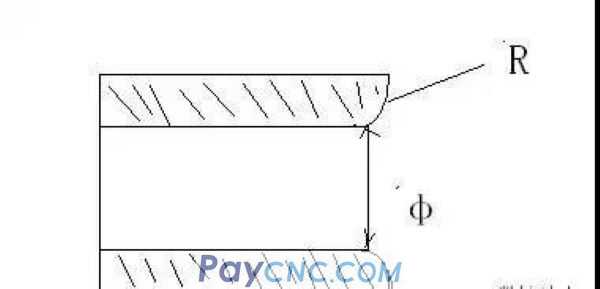

2. Calculation formula of inner circle chamfer angle

Example: Φ 20 outer end chamfer of aperture 2x60°

Program: Go X18 Z2

1. Starting point diameter of chamfering X= Φ+2xaxtanθ° x=20+2x2x1.732=26.928 G1 x26.928 Z0 F0.2

2. Starting point length of chamfering Z=0 G1 X20 Z-2 F0.15

3. Diameter of chamfering point X= Φ; G1 Z-30

4. Length of chamfering point Z= -a. . . . . .

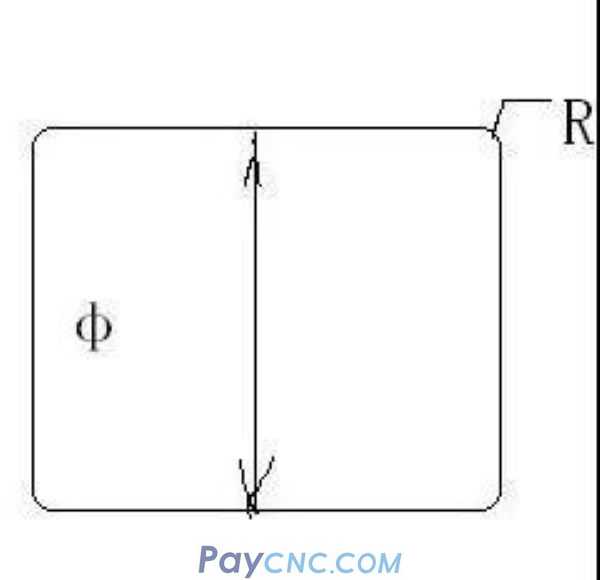

Third, the calculation formula of the outer round corner

Example: Φ 35 diameter outer end fillet R3

Program: Go X36 Z2

1. Starting point diameter of chamfering X= Φ-2*R X=35-2x3=29 G1 X29 Z0 F0.2

2. Starting point length of chamfering Z=0 G3 X35 Z-3 R3 F0.15

3. Diameter of chamfering point X= Φ; G1 Z-30

4. Chamfering point length Z=-R. . . . . .

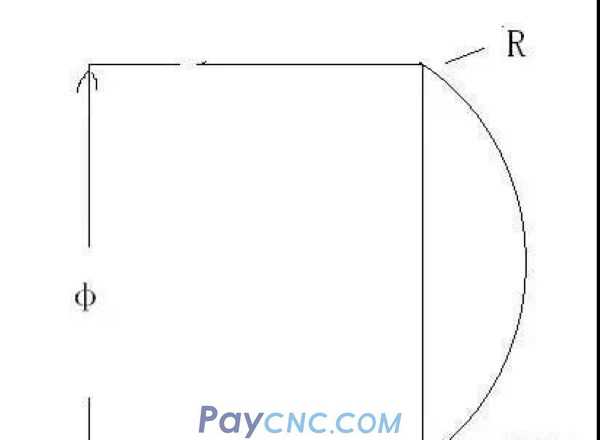

Four, the calculation formula of the inner circle round corner

Example; Φ 20 rounded corner of the outer end of the aperture R2

Program: G0 X18 Z2

1. Starting point diameter of chamfering X= Φ+2*R X=20+2x2=24 G1 X24 Z0 F0.2

2. Starting point length of chamfering Z=0 G2 X20 Z-2 R2 F0.1

3. Chamfering point diameter X= Φ; G1 Z-25

4. The length of the chamfering point Z=-R. . . . . .

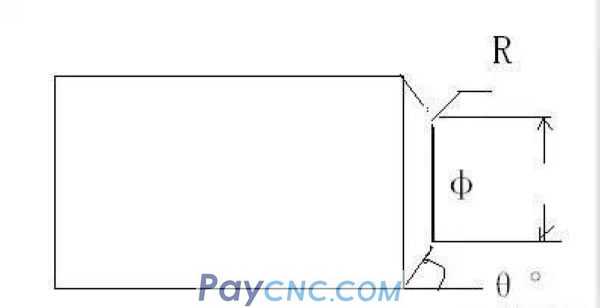

5. Calculation of R taper value of G90 and G92 CNC commands:

Example: Big end Φ35, small end Φ32, cone length 20, tooth length 16mm, 3mm cutter

1. Calculate the taper ratio value on the graph:

(32-35)/20=-0.15 program; G0 X37 Z3

(Starting end diameter-receiving end diameter) ÷ cone length

G92 X33.8 Z-16 R-1.425 F2

2. Calculate the actual R value of G92 (the radius difference from the starting end to the ending point when turning teeth): -0.15X1/2X(16+3)=-1.425 X33.1

Taper ratio x1/2x (effective tooth length + knife position) X32.6

3. Diameter of the closing point of G92: 35+(-0.15X(20-16))-2X1=32.4 X32.4

Cone end diameter + taper ratio x (cone length-effective thread length)-2x tooth height. . . . .

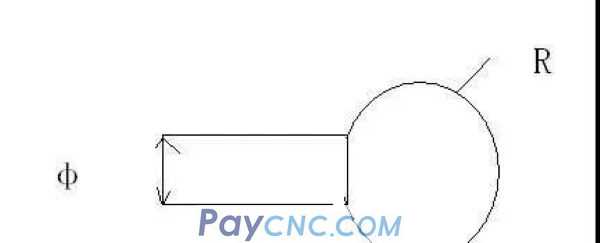

6. The height calculation formula of the spherical crown:

1. When the section is a minor arc. The height of the spherical cap = the square root of the variance of R-【R2-(X/2)2)】

2. When the section is a superior arc. Spherical crown height=R+[R2-(X/2)2)] square root of variance

For example: Φ 35 outer diameter front end car made an R50 arc surface

Bow height=R50-[R50 power-(35/2) power] square root of variance=3.162

Program: S800 M3G99T0101

G0 X36 Z2

G71 U2 R1 F0.25

G71 P10 Q40 U0.8 W0.1

N10 G0 X0

N20 G1 Z0

N30 G3 X35 Z-3.162 R50

N40 G1 X36

G70 P10 Q40 S1500 F0.1

G0 X100 Z50

M5

M30

For example: Φ40 bar stock car-made R20 sphere with Φ18 tail shank

Bow height = R20 + [R20 power-(18/2) power] square root of variance = 37.86

Program: S800 M3G99T0101

G0 X41 Z2

G71 U2 R1 F0.25

G71 P10 Q40 U0.8 W0.1

N10 G0 X0

N20 G1 Z0

N30 G3 X40 Z-20 R20

N40 G1 X41

G70 P10 Q40 S1500 F0.1

G0 X100 Z50

T0202

G0 X44 Z-37.86

G72 W2.5 R0 F0.25

G72 P50 Q80 U0.8 W0

N50 G0 Z-20

N60 G1 X40

N70 G3 X18 Z-37.86 R20

N80 G1 Z-37.86

G70 P50 Q80 S1500 F0.1

G0 X100 Z50

M30

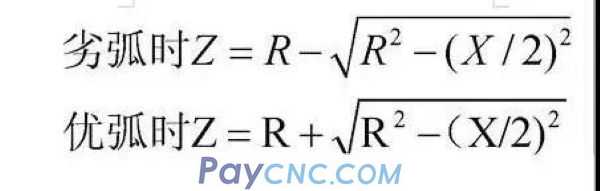

7. Calculation of the connection point of the cone and sphere combination:

1. Top X=0 Z=0

2. The tangent point of the arc and the cone X=2xRxcosθ°

Z= -(1-Sinθ°)xR

Receiving point X = cone large end Φ Z = -(Φ-tangent point X)÷2÷tanθ+tangent point Z

For example: Φ32 bar stock car made a 60 degree center with R3 front end

The arc and cone tangent point X=2*3*0.866=5.196

Z=-(1-0.5)*3=-1.5

Cone big end=32

Cone big end=-(32-5.195)÷2÷0.57733+(-1.5)=-24.713

Program: S700 M3G99T0101

G0 X32.5 Z2

G71 U2 R1 F0.25

G71 P10 Q40 U0.8 W0.1

N10 G0 X0

N20 G1 Z0

N30 G3 X5.196 Z-1.5 R3

N40 G1 X32 Z-24.713

G70 P10 Q40 S1500 F0.1

G0 X100 Z50

M5

M30

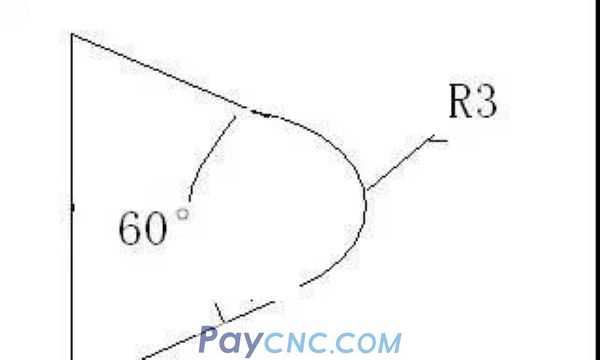

8. Calculation of Frustum Fillet:

1. Starting end X =Φ-2R【 (1-sin θ)*tanθ-cos θ】Z=0

2. Tangent point X =Φ+2R (1-sin θ)*tanθ Z =-(1-Sinθ)*R

3. The closing point X= the diameter of the large end of the cone Φ Z = -(Φ-tangent point X)÷2÷tanθ+the Z of the tangent point (that is, the length of the cone)

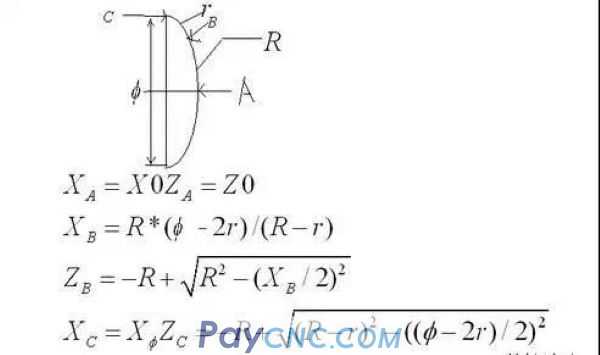

Nine, the joining of large arc R and small arc r:

1. Starting end X=0 Z=0

2. See the figure above for the cut point X Z

3. The closing point X = Φ Z = see the figure above

For example, the diameter of 100 rod car R80 big ball end, r10 curling

S500M3T0101G99

G0 X102 Z2

G71 U2.5 R1 F0,25

G71 P10 Q50 U0.8 W0.2

N10 G0 X0

N20 G1 Z0

N30 G3 X91.428 Z-14.347 R80

N40 G3 X100 Z-22.554 R10

N50 G1 Z-23

G70 P10 Q50 S800 F0.12

G0 X150 Z50

M5

M30

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|