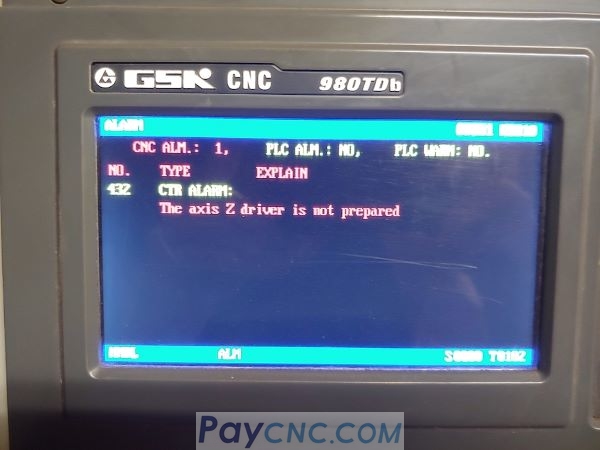

Hello Liam, You can refer to page 25 of attached manual, it says the possibilities of the Err-2. For this 110SJT-M060D(A) motor must use the DA98A driver. ------------------ Best regards. King Huang Sales Manager ------------------------------ CNCmakers Limited Mobile: +86-139-25042139 (Whatsapp&Wechat) Tel: +86-138-24444158 Fax: +86-20-84185336 Skype: CNCmakers Email: paycnc@paycnc.com cnc@CNCmakers.com Website: www.CNCmakers.com Online Shop: www.paycnc.com Add: No.168, Xiadu Road, Haizhu District, Guangzhou, China 510300 ------------------ Original ------------------ From: Date: Sat, Jun 22, 2019 06:54 AM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair Also, is there another servo drive that would work with this system? Maybe something more robust? On Fri, Jun 21, 2019 at 3:54 PM Liam wrote: Thanks, Do you know why the servo drive would be getting hot? Could it be that the alarm is high, which would turn the braking circuit on? Are there any more tests that can be ran? -Liam On Thu, Jun 20, 2019 at 10:48 PM paycnc<paycnc@paycnc.com> wrote: Hello Liam, Sure, below you may find the prices of them, any question please let us know. https://www.paycnc.com/da98a-20-ac-servo-driver_p0101.html https://www.paycnc.com/110sjt-m060d-a-motor_p0190.html ------------------ Original ------------------ From: Date: Fri, Jun 21, 2019 12:43 PM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair Could I also get a 2 quotes. One for the servo drive alone. And another with the servo drive and motor/encoder. Thanks, Liam On Thu, Jun 20, 2019 at 10:13 PM wrote: Ok good to know. I'm stumped. Do you have any ideas? I can try them this weekend. On Thu, Jun 20, 2019, 10:11 PM paycnc<paycnc@paycnc.com> wrote: Hello Liam, It does not matter. Only will turn the motor in wrong direction. ------------------ Original ------------------ From: Date: Fri, Jun 21, 2019 12:08 PM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair Yes. But do the input phases matter. For instance, if the phases were hooked up in the wrong order. On Thu, Jun 20, 2019, 10:07 PM paycnc<paycnc@paycnc.com> wrote: Hello Liam, The input power for the motor and driver should be 220V/3phase. Is it what you providing for them? ------------------ Original ------------------ From: Date: Fri, Jun 21, 2019 12:03 PM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair I'm not moving it. It gets too hot too fast and I'm worried it will ruin the x axis drive also. Not the motor phases the 220V 3 phase input. If those were wrong would that cause this type of problem? What causes the brake circuit to activate? On Thu, Jun 20, 2019, 9:59 PM paycnc<paycnc@paycnc.com> wrote: Hello Liam, There is mark on the cable, it can not be wrong, or there will be an alarm,and it will not burn the motor, just motor rotation direction could be wrong. Is the motor hot? or vibrating too much? ------------------ Original ------------------ From: Date: Fri, Jun 21, 2019 11:31 AM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair Blue brown black are which phases in China? We have red black white. On Thu, Jun 20, 2019, 9:28 PM wrote: If the alarm is set. That would put the brake on? Then the servo drive would get very hot. The x-axis drive is getting very hot when powered on which means the alarm is making this happen. Is this related to the input power phases? Perhaps they're one phase off? On Thu, Jun 20, 2019, 9:23 PM paycnc<paycnc@paycnc.com> wrote: Hello Liam, You can tried the swap the cables, the problem could come from the cables. ------------------ Original ------------------ From: Date: Fri, Jun 21, 2019 10:43 AM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair Ok, I wired the Z-axis motor/encoder into the x-axis servo drive. Once I power it up, it starts to get hot just like the Z-axis drive did when it was powered on. It was powered on for maybe 30 seconds before it got hot, I immediately shut off the machine and let air flow across the servo drive. The X-axis drive never got hot before making me thing that there is something wrong with the Z-axis motor/encoder. No error was displayed on the servo drive. I never got to test changing parameters, as I don't want to run it while itget's so hot, to avoid having 2 bad servo drives. So now I need to test the motor/encoder combo. What would cause the braking resistor to become engaged and make the servo drive hot? Thanks for your help, Liam On Thu, Jun 20, 2019 at 7:18 PM paycnc<paycnc@paycnc.com> wrote: Hello Liam, PA009 is for CNC controller 980TDb, you can find Z axis and disable the alarm. ------------------ Original ------------------ From: Date: Fri, Jun 21, 2019 09:13 AM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair Sounds good. And I adjust PA009 on the bad servo drive? Such that the controller doesn't get an alarm signal from it. On Thu, Jun 20, 2019, 7:06 PM paycnc<paycnc@paycnc.com> wrote: Hello Liam, The motors sizes are similar, and if you test them without cutting, they will be fine. ------------------ Original ------------------ From: Date: Thu, Jun 20, 2019 11:53 PM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair Sounds good. I'll test tonight and let you know. I'm safe to swap to the other servo drive? Even though it's a smaller servo driver? On Thu, Jun 20, 2019 at 12:09 AM paycnc<paycnc@paycnc.com> wrote: Hello Liam, I have no such schematic of the servo drive brake circuit. If I have it, surely I will give it to you. ------------------ Original ------------------ From: Date: Thu, Jun 20, 2019 01:11 PM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair I'll double check the connections in the morning and let you know. Is there a schematic of the servo drive brake circuit? On Wed, Jun 19, 2019, 11:05 PM paycnc<paycnc@paycnc.com> wrote: Hello Liam, Err-2 of the Z driver DA98A-15, means the cable is not connected well. Could you please kindly check connection? If the connection is fine, then the DA98A-15 driver could be already broken. Do you mean the brake resistor inside the driver, it must be changed in our factory. And it might not the problem, could be PCB board broken. You can refer to the user manual how to change the parameter, it is not easy to say it by email. And the password to enable parameter switch is 797808, you can try. ------------------ Original ------------------ From: Date: Thu, Jun 20, 2019 12:51 PM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair Hello, The alarm code on the Z-axis servo drive is ER 2. No error shown on the X-axis drive. The lathe is powered by same power as my milling machine, which runs fine. The controller has the attached error message. The Z-axis servo drive gets very hot after being powered on for only a few minutes. The X-axis is cool to the touch. Please provide instructions to change parameters, such that I can swap controllers and test the motor/encoder. I owe you a beer once this is done. Thanks, Liam On Wed, Jun 19, 2019 at 10:05 PM paycnc<paycnc@paycnc.com> wrote: Hello Liam, What is the alarm code on the display? We can identify the alarm code on 980TDb or DA98A-15, so we can know which part is wrong. And we can adjust parameter PA009 to disable the alarm, so you can test. ------------------ Original ------------------ From: Date: Thu, Jun 20, 2019 11:27 AM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair I checked and get 1.5 ohms between motor phases on the 060(A) and 2.5 ohms between phases for the 040(A). No short between PE and motor phases on either axis. The 040 is the working X-axis. I won't be able to test with the other drive, as the controller gives a Z-axis fault when powered up, and it cannot be ran. Do these values sound correct for the motor phases resistance? Is there an encoder test that can be ran? Thank you for the help Liam On Wed, Jun 19, 2019 at 9:12 PM paycnc<paycnc@paycnc.com> wrote: Hello Liam, You can measure if there is short circuit between UVW and PE or not? If there is no any short circuit, then you can exchange the drivers from another axis to test. so we can identify the problem come from the driver itself or from others. For motors you can use the same way to check. You can check first, then we will make quotation for the defected one for you, okay? ------------------ Original ------------------ From: Date: Thu, Jun 20, 2019 10:36 AM To: "paycnc"<paycnc@paycnc.com>; Subject: Re: GSK DA98A-15 Servo Drive Repair I understand. Thank you for the information. Attached are the pictures of the servo drive and controller, which I believe has the motor information as-well. I'm more concerned about what caused the failure, such that when I install a new servo drive, it does not also burn up. I was hoping the repair would tell me what caused the problem as well. If you shared the schematics or any other info with me, I might be able to determine what caused it to go bad. Is there a way to test the motor and encoder to determine if they're bad, before installing the new servo drive, to ensure this doesn't happen again? Do the input power phases matter? If a mix up to the input power cause the servo drive to fail? Can you also price a motor/encoder combination. I worry that a bad motor or encoder caused the servo drive to fail. The machine this is going on is a Bolton BT6132 CNC Lathe, if that helps. Thank you for the help, Liam On Wed, Jun 19, 2019 at 8:08 PM paycnc<paycnc@paycnc.com> wrote: Hello Liam, The DA98A-15 was old model and it must have been used for long time. It is not 100% can be repaired or not, we only can be sure when we check it physically. Even it can be repaired, the spare part and double shipping and custom costs from your country to China could be costly. We suggest you can buy a new driver,so it can save one way shipping and custom cost. And the new one will be surely good to used. Could you please kindly take name plate photos of the driver and the motor and the controller, we will select the right driver model, and quote to you with shipping cost accordingly. We will also need your detail address, zip code, telephone number to check DHL cost for you. ------------------ Original ------------------ From: Date: Wed,Jun 19,2019 11:25 PM To: support <support@cncmakers.com> Subject: Fw: GSK DA98A-15 Servo Drive Repair Hello, Can you tell me how to go about sending this servo drive in for repair? Also the estimated price (min-max) for such a repair. Know very little about the problem. Is it better to just replace with a DA98A-20? Thank you,

.jpg)

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|