The CNC tool holder is the most common auxiliary device for CNC lathes. It allows the CNC lathe to complete multiple or even all processing procedures in one clamping of the workpiece, thereby shortening the auxiliary time of processing and reducing the need for multiple installations of the workpiece during the processing. Errors caused by the machine tool, thereby improving the processing efficiency and processing accuracy of the machine tool.

The development trend of CNC tool holders is: with the development of CNC lathes, CNC tool holders begin to develop in the direction of quick tool change, electro-hydraulic combination drive and servo drive.

At present, domestic CNC tool holders are mainly electric, divided into two types: vertical and horizontal. The vertical tool holder has four and six stations, which are mainly used for simple CNC lathes; the horizontal tool holder has eight, ten, and twelve stations, which can rotate in forward and reverse directions, and can be used to select tools nearby. Functional CNC lathe. In addition, horizontal tool holders also include hydraulic tool holders and servo-driven tool holders.

Market analysis of CNC tool holders: Domestic CNC lathes will develop in the future. Mid-range CNC lathes will adopt popular CNC tool holders, powered tool holders, hydraulic tool holders, servo tool holders, vertical tool holders and other varieties. In recent years, The required quantity can reach 10,000 to 50,000 units.

Direction of development

First, high speed and reliability, the pursuit goal is to shorten the tool changing time as much as possible in exchange for the performance of machining centers and turning centers;

Second, it is simple and practical, low in cost and reliable in use, but the tool change speed is not fast.

Development and application of CNC tool holder

The CNC tool holder uses rotary indexing to realize automatic tool exchange and transmission of rotary power tools. Therefore, the technical content is high and it has tended to be specialized in development and production. Therefore, the research, development and application of CNC turret tool holders have attracted the attention of the CNC machine tool industry.

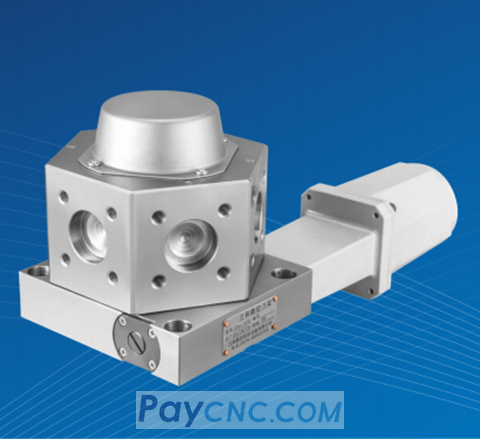

A typical CNC turret tool holder generally consists of a power source (motor or cylinder, hydraulic motor), mechanical transmission mechanism, pre-indexing mechanism, positioning mechanism, locking mechanism, detection device, interface circuit, tool mounting table (cutterhead), power Composed of knife holder, etc. The action cycle of the CNC turret tool post is: T command (tool change command - cutter head rotation - tool position detection - pre-dividing - positioning - cutter head locking - end signal. |