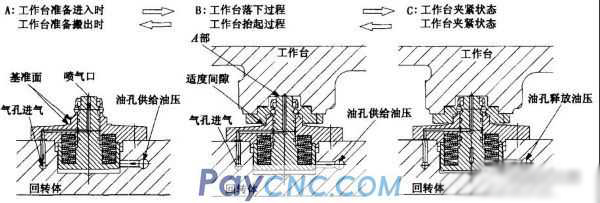

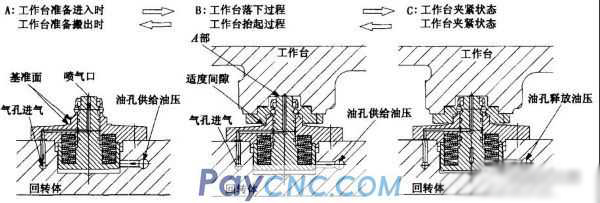

A: When the workbench of the vertical machining center is ready to enter (when the workbench is ready to be moved out), the oil pressure and air pressure are in the supply state, and the air jets blow air to clean the positioning surface and the clamping surface to prevent foreign objects from invading people. At this time, the piston rod is located at the uppermost position of its stroke under the action of oil pressure against the spring force.

B: When the workbench is lowered (or raised), the oil pressure and air pressure are kept in the supply state, and the positioning cone and the positioning plane of the pin sleeve and the pin body are left with appropriate gaps, which can ensure frequent exchanges on the workbench Bottom, the positioning surface will not be scratched or the worktable will be squeezed due to chip retention, and the accuracy can be maintained for a long time. When the worktable falls into contact with the piston rod at A, the displacement of the worktable stops under the support of the piston rod. At this time, there is still a distance of 1mm between the pin sleeve and the positioning plane of the pin body.

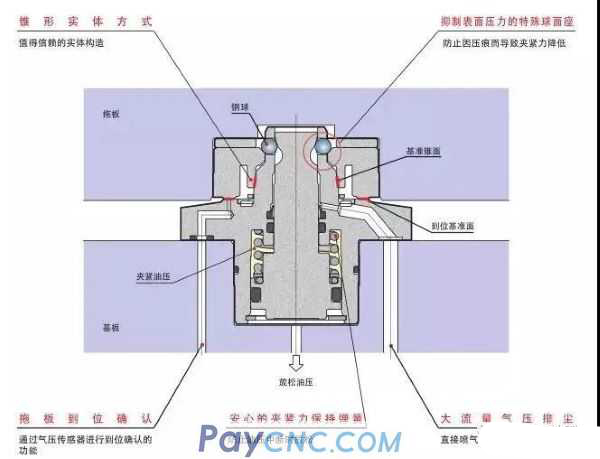

C: When the worktable is ready to be clamped, the hydraulic system is unloaded, the piston rod moves down under the action of the spring force, and the steel ball moves with the piston rod. During the downward movement, the hard steel ball surface presses the upper end slope of the pin sleeve , Pull the pin sleeve to the positioning surface of the pin body. When the pin sleeve is pulled, it is in full contact with the reference surface of the pin body. When the air pressure in the air path reaches a certain value, the air pressure sensor sends a signal; thus the workbench completes the center positioning and clamping action.

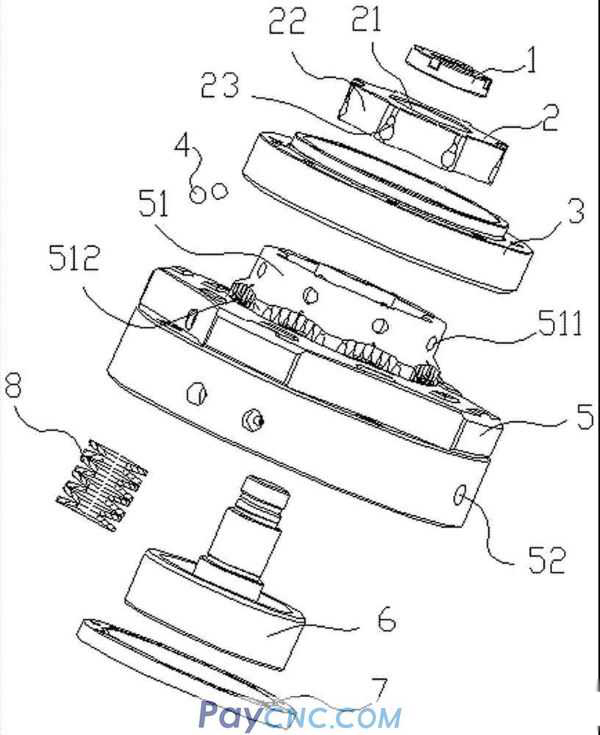

Analysis and explanation: This structure is used in conjunction with different pin bodies and pin sleeves to meet the positioning principle of two pins on one side. The spring force is used to clamp evenly distributed steel balls, and the positioning point and the clamping point coincide

|