|

GSK 218MC CNC system

Transformation and application of spline shaft milling machine

Using hobbing and cutting methods to process various tooth-shaped straight tooth spline shafts, can also hoist straight tooth gears and spur gears, and can taper spline and step gears;

Provides a parameterized operation interface for the user. The user can choose the processing program of cylindrical gear, bevel gear, worm gear, drum gear according to the workpiece situation. Enter the tool parameters, workpiece parameters, process parameters and feed times, and the system will automatically generate Processing program without any programming instructions;

The hob shaft is transformed into a servo motor drive and can process any number of teeth. Special hobbing instructions are adopted to realize the linked hobbing gear. Set the number of processing teeth, workpiece rotation speed, and processing depth of teeth through simple programming instructions;

After the power is turned off and restarted, the last completed processing program can be run (the rough cutting is performed after the power is turned off, and the power is turned on and the finishing processing is continued).

solution

Modify the system software version to V1.6 EGB-GR.3 20190828;

There are 4 axes of X, Z, A, and B, all of which are servo control axes. The A axis is used to control the workpiece rotation axis, and the B axis is used to control the hob rotation axis. During machining, the hobbing command G181 is used to achieve the accurate rotation relationship and rotation speed of the A and B axes to achieve gear rolling; the X axis is the gear radial feed axis for controlling the radial positioning of the rolling; the Z axis It is a gear axial feed control shaft for controlling the movement feed along the gear axis;

Because the hob shaft of the hobbing machine has an external gear ratio, that is, the motor shaft and the machine tool spindle are not a 1: 1 transmission ratio. The hobbing function needs to continue processing the same workpiece after the power is turned off, and the hob shaft must be oriented to the same position, so a second position encoder or home switch must be installed. This customer chose to install a zero return switch;

Because the hob shaft and the rotary table must have reverse clearance, the direction must be consistent with the machining direction when returning to zero and moving the shaft, so as to ensure that the zero positions of the two axes will not deviate after the power is turned off and on again.

Application effect

System supporting quantity: 3 units;

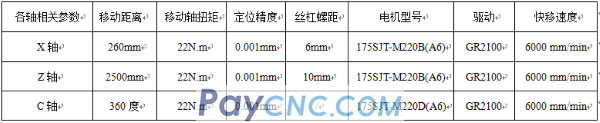

technical parameter

The four CNC axes are: B—the revolving motion of the hob spindle, C—the rotary motion of the table, x—the radial feed motion, and Z—the axial feed motion

It can realize hobbing spur gears and spur gears, and can process taper splines and step gears;

Each mechanical system and component of the CNC spline shaft milling machine has high dynamic and static rigidity, and the tool is driven by an AC inverter motor with high power and smooth operation;

Automatic tool shifting device and efficient dry cutting can guarantee the processing quality and efficiency of the workpiece;

Applicable to automobile, tractor, gear processing and other related machinery manufacturing industries, realizing high-efficiency machine tools capable of mass production of spline shafts and gears;

Can achieve a variety of gear processing such as milling and slotting.

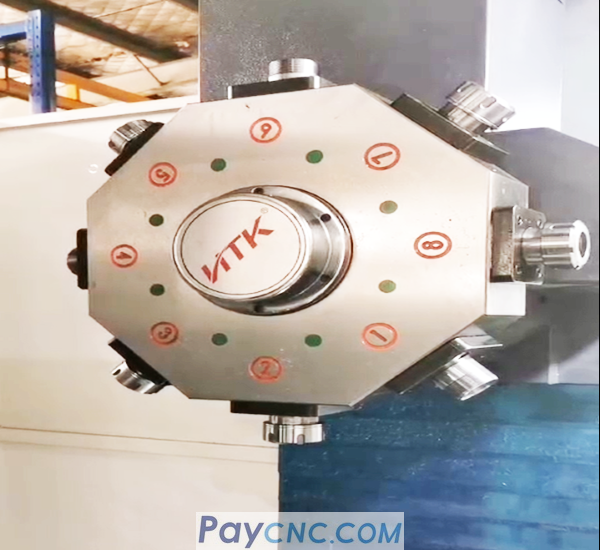

02 Application of GSK218MC-V CNC Drilling Center

The number of system control axes is 4 axes;

Realize PMC axis servo tool magazine control function;

Achieve quick tool change and high-speed tapping.

solution

Use 218MC control for function development on V1.5 version;

Use PMC axis control function to realize servo tool post control;

Automatic tool change macro program, break enable, fast tool change and PMC axis control ladder diagram writing.

Application effect

Quick tool change, greatly reducing workpiece time, improving efficiency and reducing costs;

Can achieve multiple types of processing such as drilling, tapping, milling plane, etc., to achieve a variety of processed products;

The maximum tapping speed of the spindle is 3000 revolutions.

03GSK 218MC-V CNC System Tool Grinder Reconstruction and Application

Five-axis five-linkage and eight-axis five-linkage can be realized;

Achieve suitable for processing circular shank tools, such as overall milling cutters, IT tools, woodworking tools, medical tools, drills, reamers and other hole processing tools

Achieve automatic loading and unloading and automatic inspection of tool qualification accuracy.

solution

Use 218MC-V control for function development on V1.5HJ version;

Added a tool grinder interface customized for Wuhu Machine Tool Factory to facilitate the input of various processing parameters;

Add a tool detection interface to facilitate the user to measure the tool geometry;

Add grinding wheel grinding performance detection interface, which can modify the grinding wheel parameters, tool parameters, and grinding process online. It is easy to use and meets the operator's habits.

Application effect

So far, the average system demand is about 70 sets;

Enter processing parameters to generate processing programs, saving time for manual editing in the system panel, which can shorten the effective time of workpiece production and improve production efficiency;

Dedicated interface, concise and convenient, customers only need to fill in relevant variables, and can automatically generate processing programs

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|