GSK 988T CNC system is used for overhaul and upgrade of Demaji CTX double turning machining center

The original machine tool has many problems: the original machine tool CNC system fails to start normally; the ball screw, screw bearing and linear guide are worn; the two spindles are not concentric; the spindle axis is not vertical; the lubrication, cooling, and pneumatic system pipeline aging;

Need to replace the supporting CNC system, restore the accuracy of the machine tool, replace the aging parts.

solution

Adopt GSK 988T numerical control system, supporting servo motor and servo drive to upgrade;

Replace the four feed shaft ball screws, screw bearings, and linear guides;

Overhaul electric spindle, power turret, grating ruler, hydraulic pressure, lubrication, cooling system, etc., restore all functions of the original machine tool and adjust the geometric accuracy of the machine tool;

Redesign the electrical control schematic diagram of the machine tool, replace the electrical control and electrical components and re-wire.

Application effect

Restore the precision of the machine tool and all functions used, and run stably;

Meet customer parts processing requirements.

02

GSK 988T CNC system is used for overhaul and upgrade of CTX-twin turning machining center

The center height of the turret and the main shaft are deviated; the position of the servo turret is not accurate; the seal of the protective cover of each linear axis is damaged; the CNC system and pipeline are aging;

Need to replace the supporting CNC system, restore the precision of the machine tool, replace the aging parts, install automatic chip conveyor, install pneumatic door.

solution

Adopt GSK 988T numerical control system, supporting servo motor and servo drive for transformation;

Adjust the main shaft base and the turret to ensure that the center height of the main shaft and the turret is equal;

Repair the turret and replace it with a wide number of servo motors to drive the turret to rotate; fine-tune the position of the detection switch to ensure the accurate position of the tool change;

Replacing the sealing strip of the protective cover of each shaft to protect the screw rod and guide rail of each shaft;

Add chain plate type automatic cooling chip removal system, the chip removal device is installed under the protective cover of the whole machine, and the chips are discharged from the right side of the machine tool;

Install pneumatic door with detection signal of door opening and closing;

Overhaul chucks, hydraulic, lubrication, cooling, pneumatic systems and replace aging parts;

Redesign the electrical control schematic diagram of the machine tool, replace the electrical control and electrical components and re-wire.

Application effect

Restore the precision of the machine tool and all functions used, and run stably;

Meet customer parts processing requirements.

03

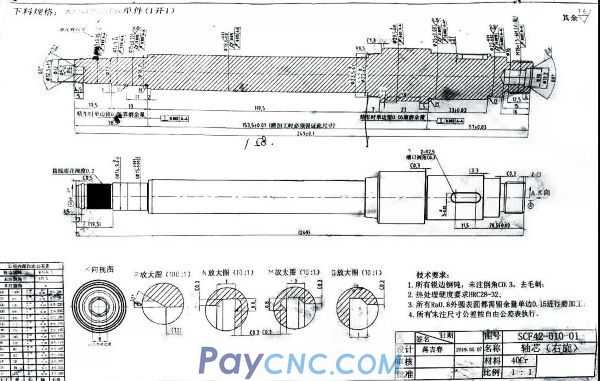

Application of CHK52, Baoji CK50S CNC lathe with GSK988T CNC system motor shaft processing

The processing material is 40Cr motor shaft core;

It is required that the processed motor shaft core is installed on the electric spindle motor to rotate smoothly at high speed, with small jitter and low noise.

solution

Use the Shenyang CHK52 and Baoji CK50S CNC lathes equipped with Guangzhou CNC system 988T to develop clamping tooling plans and processing techniques according to customer parts;

The dimensional accuracy of each process after debugging and processing is stable at 0.01mm, meeting product requirements;

Customer self-made knives;

Multi-processes can be run continuously for normal mass production;

After assembling the finished parts of the production and processing, all the indexes required for the operation requirements of the electric spindle are met.

Application effect

After processing, the shaft core meets the requirements of the drawings;

After assembly, the motor meets customer requirements.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|