|

V6C machining center product sample processing

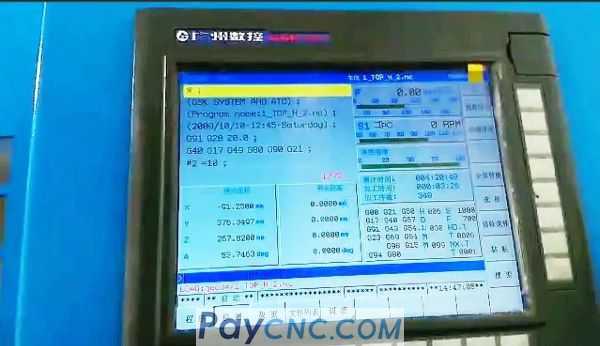

Processing with specified machine tool and system configuration (Pojia V6C with GSK25i system);

Trial machining the customer's parts according to the drawings provided by the customer and the workpiece blank;

The processing time of each workpiece required to meet the processing requirements is within three minutes;

Provide the list of tools, chucks, Latin and shank models required for the processing process for customers to purchase.

solution

Processing with specified machine tool and system configuration (Pojia V6C with GSK25i system);

Trial machining the customer's parts according to the drawings provided by the customer and the workpiece blank;

The processing time of each workpiece required to meet the processing requirements is within three minutes;

Provide the list of tools, chucks, Latin and shank models required for the processing process for customers to purchase.

Application effect

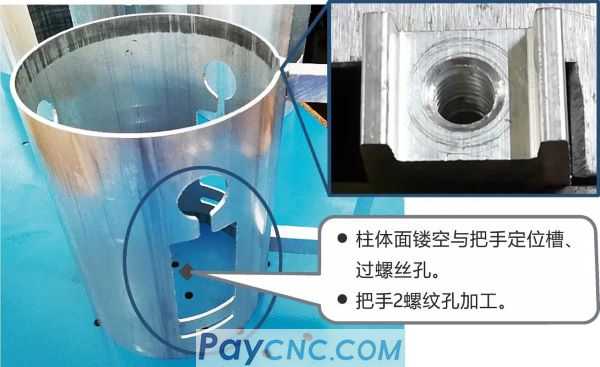

Cylindrical parts are processed at 100% magnification, and the cycle time for single piece processing is 2 minutes and 50 seconds. After small batch production, the burr becomes larger due to the wear of the tool, and the customer has trouble removing the burr manually, and agreed to increase the precision milling of the tool to reduce the burr. The customer sent another blank and processed 20 pieces. The burr on the sandpaper can be removed, and the customer is satisfied with the effect;

Handle parts, 100% processing, 10 pieces processing cycle time 3 minutes 26 seconds, a single 20.6 seconds.

2.VMC850 machine with GSK 25iMb CNC system

Machining Center

solution

Use Shandong Weida Heavy Industry VMC850 machine tool with GSK 25iMb system machining center;

Find a third party to develop a clamping tooling plan and processing technology according to the customer's parts;

Recommend and use reliable machining tools;

The dimensional accuracy of each process after debugging is stable at 0.01mm, which meets the design requirements;

Adding the fourth axis to complete multiple processes can continuously run normal batch production;

Production and processing parts can meet customer requirements after assembling other accessories.

Application effect

The dimensional accuracy of the processing adjusting arm is within 0.01mm, and the length of a single processing is controlled at about 8 minutes to meet customer needs.

3

GSK25iMb CNC system for

DMG DMC63V vertical machining center transformation

The original machine tool numerical control system (SIEMENS 810D system) could not be used normally due to aging failure, the mechanical accuracy of the whole machine could not meet production requirements, the accuracy of the spindle decreased, the tool change of the tool magazine was unstable; the pipelines such as lubrication, cooling, and pneumatic systems were aging;

Replace the supporting CNC system, replace the aging parts, and restore the precision and control functions of the machine tool.

solution

Numerical control system: GSK25iMb system (15-inch PC version, 5 axes and 4 linkages), and supporting servo drives / motors.

Redesign the electrical circuit and replace the supporting electrical components.

Added 4th axis function.

Replace the linear guide screw, bearing and other parts; overhaul the spindle and tool magazine, grind the work surface and restore the accuracy of the machine.

Replace the lubrication, cooling, pneumatic system and other parts and pipelines to restore the original machine control functions.

Application effect

Restore machine tool precision and realize original machine tool control function;

Meet customer parts processing requirements.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|