Procedures and processes

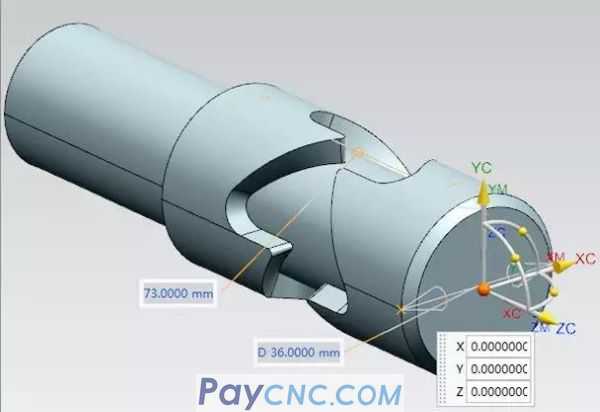

Material: part contour: diameter contour φ36, length 73;

Material model: 45 # steel.

Program, tool:

Operation 1 (roughing): O1660 (roughing, blank φ36-process / tool name: φ8R4 ball cutter \ layer milling-1mm per layer)

Step 2 (Contour Opening Rough): O1661 (Contour Opening Rough-Step 2) / Tool name: φ4 flat knife \ layer milling-0.2mm per layer);

Operation three (contour and bottom surface finishing): O1662 (contour and bottom surface finishing-operation 3 / tool name: φ4 flat knife);

Step 4 (contour chamfering): O1663 (contour chamfering-step 4 / tool name: φ4R2 ball cutter)

note:

◾ When clamping the blank, the chuck needs to clamp the workpiece to avoid interference with the power head.

◾ Machining program (Note: the beginning, end, speed and feed of the program depends on the system and machine conditions).

It can be seen from the processing pictures that the workpiece is chamfered uniformly and the bottom milling is smooth. The processing effect has been recognized by customers and meets customer requirements.

Roughness of workpiece bottom: Ra 1.1354 um

Rp 4.1687 um

Rv 2.6922 um

Rt 8.1931 um

RSm 68.7479 um

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|