|

The product has a total of 7 procedures, inserting the blades-injection molding-blanking of the injection molding machine-workpiece detection-cutting nozzle-code tray-boxing.

solution

One RB08 handling robot is equipped with corresponding equipment and equipment, instead of manually completing the production process of S knife injection molding insert material reclaiming, and packing the finished product with pallets, and manually performing material preparation and other related tasks;

The robot completes all the main tasks of the production process.

Application effect

The robot replaces the human, and can work continuously for 24 hours to complete the task steadily;

The blade is sharper, it is easy to cause the scratch of the feeding worker, and the employment is difficult. The robot solves this problem;

Developed the application of industrial robots in the S-knife-like production field, and has been widely used.

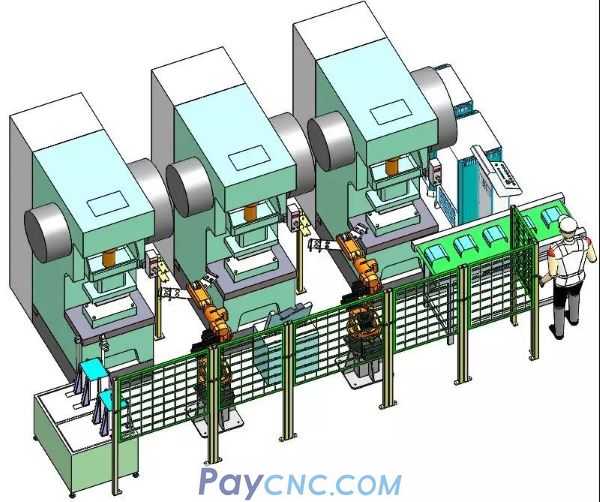

2.GSK RB08 Robot Home Appliance Company Stamping Automation Production Line Application

The robot replaces the human, and completes the transfer of three 63-ton punches and the workpieces between the upper and lower silos.

There are many product models, not many single production batches, and the robot fixture is versatile. It is necessary to achieve different shapes of products to grab and load;

The production time of the special machine is 6 seconds, and the production capacity of the production line is 350 pieces / hour.

solution

2 RB08 handling robots, 2 sets of dual-station flexible hand grips, automatic slitting and feeding machine, unloading conveying line, supporting 63 tons of punching presses, complete blanking, blanking, trimming, forming, forming production and finished Collected offline

The robot hand grip adopts a dual-station flexible design and adjusts the position of each suction cup to achieve compatibility with all workpieces for suction gripping and loading and production.

Application effect

Adopt compatible flexible manipulator design and solve the problem of multiple models and small batch production on the same production line with less manufacturing cost;

The robot operation is closely coordinated with the punch to ensure stable work, maximize production efficiency and reduce production and operation costs.

3.GSK RB08 robot car parts deburring application

Robots replace manual operations to realize the automatic production of workpiece loading, deburring and unloading.

solution

Design a set of material distribution mechanism to achieve equidistant separation, positioning and clamping of 5 stacked workpieces;

A RB08 robot is used to design a set of deburring tools to complete the tasks of deburring and chamfering of the workpiece processing edge.

Application effect

The entire robot system runs stably, saving equipment and labor investment, and ensuring good production continuity;

The replacement of robots in the grinding industry to improve efficiency and reduce costs is the general trend and also the production of technical products;

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|