There are many types of CNC machine tools. All types of CNC machine tools have different characteristics due to their different functions, structures and systems. The content and rules of its maintenance also have their own characteristics. The specific maintenance system should be formulated and established according to the type, model and actual use of the machine tool, and with reference to the requirements of the machine tool manual.

The following are some common general maintenance points.

1. Machine tool cleaning: clean up the fixtures, guards, sliding tables, etc. in the machine tool, clean the iron filings in the external chip conveyor; wipe the external sheet metal, and clean the electric control box air conditioner and oil cooler filter.

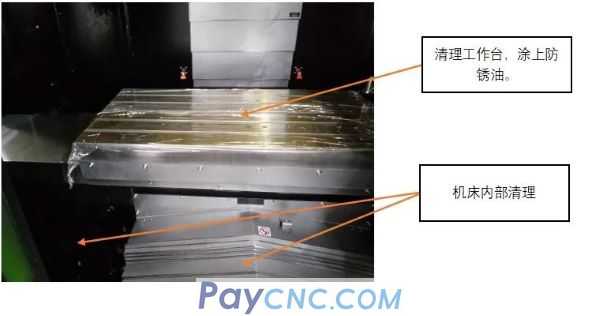

2. Anti-rust treatment: clean and wipe the workbench and apply anti-rust oil; the machine tool runs slowly for 10 minutes to lubricate the guide rail; whether the cutting fluid needs to be replaced, give priority to rust prevention, and add cutting fluid when the machine tool starts to work .

3. Make the power cut, air cut, and liquid supply cut off for the line body: Run the Y axis of the CNC machine tool to the middle, return the Z axis to zero, and turn off the power switch of the machine tool, the transformer inlet switch, and the air source.

4. Waterproof and moisture-proof: close the electrical box for protection. If conditions permit, place a desiccant in the electrical box and electrical cabinet.

5. Anti-rodent treatment of the machine tool: The machine tool should also be treated with anti-rodent to prevent the mouse from biting the wire.

Commissioning of CNC machine tools

Check before starting: check the peripheral environment of the machine tool, whether there is any abnormal phenomenon such as water in the electrical box, and whether the oil is deteriorated. Step-by-step startup: The power supply voltage of the machine tool must be checked before startup. The power switch of the machine tool must be turned on after the main power switch is turned on for about 10 minutes after the voltage is stable, and then turn on other power switches in the electrical box to check whether the voltage is missing phase and If it is too low, turn on the power of the machine tool if there is no abnormality, and observe whether there is any abnormality or air leakage. Do not perform any actions when there is no alarm when starting up, and let the electrical components energize for 30 minutes.

Slow movement: Check for interference, move the machine tool through the handwheel, and pay attention to whether there is any abnormality, and then perform the origin return step.

Machine tool running-in: Run the machine tool automatically and slowly for a long time, and rotate the spindle at low speed.

Frequent failures of CNC machine tools after long-term shutdown

Fan failure: The fan in the machine tool can dissipate heat and cool down the core equipment, effectively avoiding damage to the equipment due to overheating. At the end of the long vacation, the machine fan often "strikes", which is caused by oil pollution. When the machine is stopped, the fan inside the machine will also stop. At this time, the oil in the machine tool will flow into the fan's bearing, causing a short circuit failure in the fan's circuit, and the fan will alarm or fail to start when it is turned on again. The longer the downtime, the greater the risk.

Seal failure: Seals must be used in both hydraulic and pneumatic devices of machine tools. The purpose is to ensure the tightness of the device and maintain its normal pressure supply. Seals are generally rubber products and are prone to aging. Especially during long holidays, the machine tool will not operate for a long time and the hydraulic pressure will not flow. This will more easily cause the seals to harden, cause the machine tool to leak oil, and the pressure provided by the hydraulic device is insufficient.

Blockage of the oil circuit: The reason for the blockage of the oil circuit is due to the long-term shutdown of the machine tool and the continuous deposition of dirt in the oil circuit. Blockage of the oil circuit will cause the machine's lubrication system to malfunction, and the lubrication system will cause many other serious problems. According to statistics, more than 40% of the common failures of machine tools are related to lubrication failures.

Failure of the machine tool travel switch: The machine tool travel switch is an important device that limits the mechanical travel range of the machine tool coordinate axis. When the moving part of the machine presses on the transmission part of the travel switch, its internal contact action will switch on, change or break the control circuit. Meet the control requirements of the circuit. The travel switch is generally equipped with a spring. If it is not turned on for a long time, the spring will not be able to return to its original state due to long-term force deformation, the spring will lose its function, and the entire travel switch will be stuck and fail.

Drivers, power supplies, motherboards and other circuit board failures: in CNC machine tools, the role of the circuit board need not be said. The circuit board has a large number of capacitors. If it is not energized for a long time, these capacitors will age, reduce the capacity, and cause damage to the machine tool circuit. In addition, the main reason for circuit board failure is that if it is not used for a long time, the circuit board will be in a low temperature state for a long time, which will produce condensed water and cause a short circuit when starting up.

Machine tool battery failure: Generally, the CNC system is equipped with a battery. It should be noted that the battery mentioned here is not the power source of the entire equipment, but a device that supplies power to some parts. For example, the system battery is used to save the system parameters; the absolute position encoder battery is used to remember the zero position. Even when the battery is not turned on, the power in these batteries will slowly drain. If the battery is not turned on for a long time, the battery will be drained and the machine data will be lost.

Avoidance of failures of CNC machine tools during long-term shutdown

1. For machine tools that have been used for a long time, try not to turn off the machine during the long holiday, and you can take an emergency stop.

2. Regularly check the system fan. If it is contaminated with too much oil, it should be replaced or cleaned up. If it has been used for more than 3 years, it must be replaced.

3. Regularly check the hydraulic oil pressure, liquid level and hydraulic impurities in the hydraulic system to ensure the smooth flow of the oil path.

4. Regularly clean or lubricate the parts with springs such as the stroke switch, knife arm spring, hydraulic valve spring, etc.

5. According to the oil contamination of the drive equipment, clean it regularly.

6. Regularly replace the system battery for the machine tool and replace the desiccant for the electrical cabinet of the machine tool, especially before shutting down during a long holiday. This step must not be forgotten.

7. After the long vacation, before restarting, ensure that the temperature around the machine tool is normal.

Additional information:

1. Remove the tools from the tool magazine and put them back into the tool magazine cabinet, and the tools are treated with rust prevention.

2. Spindle oil cooler:

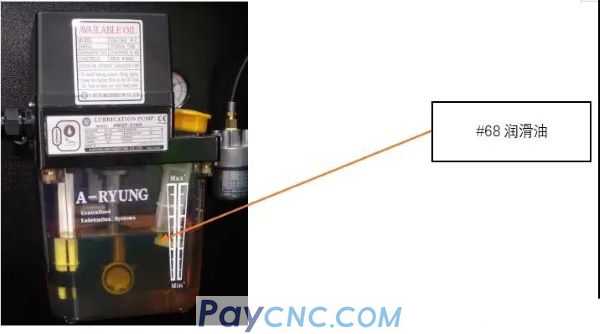

3. Screw lubrication system:

4. Manipulator and spindle cleaning:

5. Workbench and machine internal cleaning:

6. Electric cabinet air-conditioning filter:

7. Electric cabinet part:

8. System:

9. Water tank:

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|