FANUC debugging video tutorial is here

In the machining center, the more complicated maintenance part is the tool magazine. It is not difficult, but lacks maintenance tools. The maintenance tool is PMC. The tool does not move and it is stuck. What is the reason?

The tool change stopped suddenly, sporadically? How to do?

If the machine has an alarm, we can find the cause of the fault based on the alarm. What if there is no alarm?

The following is a solution to the stuck tool caused by the accidental loss of orientation when changing the tool:

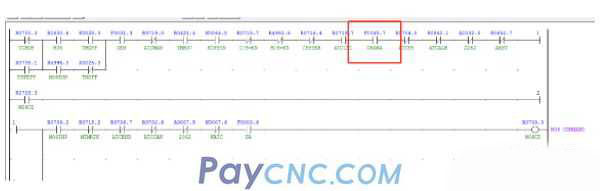

As shown in the figure below, when changing the tool, the PMC signal will monitor the spindle orientation completion signal. This signal is connected to the tool change command in series. If the orientation signal is lost due to the force on the spindle orientation during tool change, a tool jam will occur.

The solution is to monitor only when the ATC is from 0 degrees to the buckle position in the PMC program.

The program shown above is sufficient, but some machine tools will ignore the programming of this part of the program. How is your machine controlled?

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|