In processing, accuracy and speed always restrict each other. When roughing, we need to be more inclined to speed; when finishing, we need to be more inclined to accuracy.

In fact, in the Haas system, we have special codes to let users choose the focus.

G187 set smooth level (group 00)

G187 is a precise command, which can set and control the smoothness and maximum fillet value when cutting the workpiece. The format using G187 is G187 Pn Ennnn.

P controls the level of smoothness, P1 (rough machining), P2 (medium) or P3 (finish machining).

E Adjust the maximum fillet value, temporarily overwriting the setting 85 "max fillet".

When G187 is not activated, setting 191 sets the default smoothness for the user, including "rough machining", "medium" or "finish machining". Add WeChat: Yuki7557 will send a copy of the macro program tutorial, the "medium" setting is the factory default setting. Note: Changing setting 191 to "finishing" will require more time to process the workpiece. Use this setting only when you need the best finishing.

G187 Pm Ennnn Set the smoothness and maximum fillet value.

G187 Pm sets the smoothness but does not change the maximum fillet value.

G187 Ennnn sets the maximum fillet but does not change the smoothness. G187 cancels the E value by itself, and sets the smoothness to the default smoothness specified in Setting 191. When the reset key (RESET) is pressed, M30 or M02 is executed, the program execution ends, or the emergency stop key (EMERGENCY STOP) is pressed, G187 will be cancelled.

Users can choose the most suitable processing mode according to their needs to improve processing efficiency.

In terms of CAD/CAM software, the modification of CAD models has become more and more convenient, and the CAM software has become more and more intelligent. New machining strategies (such as dynamic milling) give users the opportunity to obtain very high metal removal rates, which can significantly improve machining efficiency.

In terms of algorithms, some CAM software (such as AUTODESK FUSION360) can optimize a large number of G01 codes to the greatest extent, and output the same precision G02/G03 codes under the condition that the amount of code is greatly reduced, so that the machine can execute more Fast, thereby improving processing efficiency.

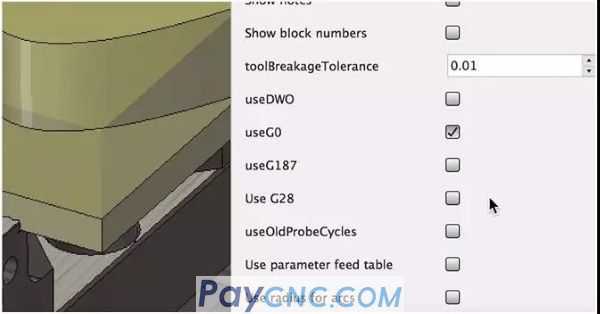

The selection of G187 (processing mode) can be opened through the software, or manually added to the processing program according to the previous instructions. For the same processing program and processing machine, turning on the roughing mode (G187 P1) may save 20% of the execution time than the default medium mode (G187 P2). Choosing the correct processing mode can see a very obvious difference.

If you use the default medium mode (G187 P2) for finishing and find that there are dents in the clear corners, you may need to learn about the finishing mode (G187 P3) at this time. After watching the video below, you can not only solve the current problem, but MARK will also teach you his favorite corner cleaning strategy.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|