The universal angle ruler is designed according to the principle of the vernier caliper. It is a measuring tool for measuring the inner and outer angles of the workpiece. It is widely used in mechanical engineering. I believe that many designers who are just getting started do not know how to use the angle ruler. Today I will talk about the universal angle ruler. usage.

Universal angle ruler, also known as angle gauge, vernier angle ruler and universal angle gauge, is a kind of angle measuring tool that uses the principle of vernier reading to directly measure the angle of the workpiece or scribe. The universal angle ruler is suitable for internal and external angle measurement in machining, and can measure 0°-320° external angle and 40°-130° internal angle.

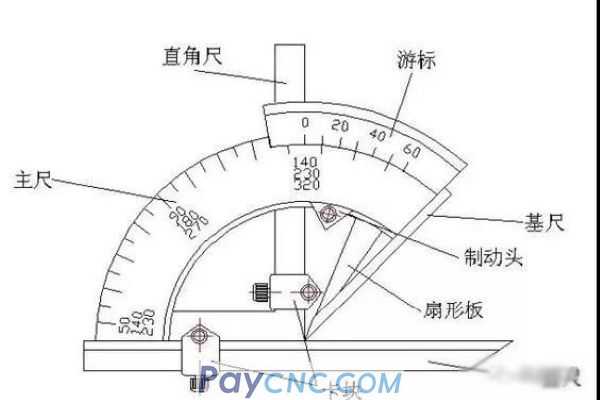

The reading mechanism of the universal angle ruler is made according to the principle of vernier. The scale of the main ruler is 1° per division. The scale of the vernier is divided into 30 divisions from 29° of the main ruler, so the scale of the vernier scale is 29°/30, that is, the difference between the main scale and the vernier is 2', which means that the universal angle scale reading The accuracy is 2'. In addition, there are two precisions of 5'and 10'. The reading method is exactly the same as that of vernier calipers.

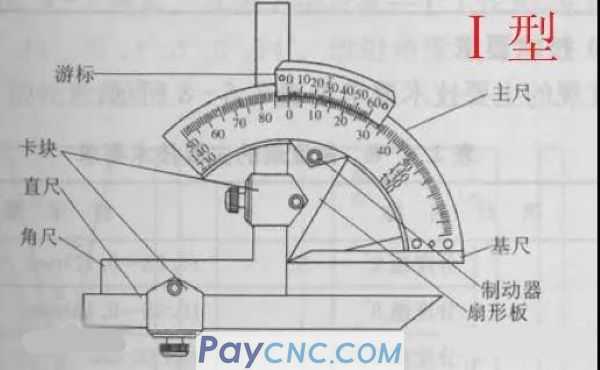

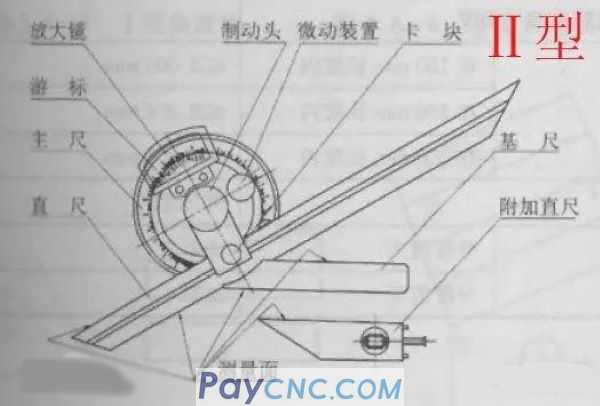

Part 2 structure introduction

The universal angle ruler is a measuring tool used to measure the internal and external angles of the workpiece. Its structure is shown in the figure.

Part 3 How to use

When measuring, the zero position should be calibrated first. The zero position of the universal angle ruler is when both the square and the ruler are installed, and the bottom edge and the base ruler of the angle ruler and the ruler are in contact with the ruler without gaps. At this time, the main ruler and the vernier "0" Line alignment. After adjusting the zero position, any angle within the range of 0-320° can be tested by changing the mutual position of the base ruler, square ruler and ruler.

When using a universal angle ruler to measure a workpiece, the ruler must be appropriately combined according to the measured angle.

The structure of the universal angle ruler: It is composed of a ruler body, a 90° angle ruler, a vernier, a brake, a base ruler, a ruler, and a clamp block.

Measuring range of universal angle ruler

The vernier universal angle ruler has two types, type Ⅰ and type Ⅱ, and the measuring ranges are 0°~320° and 0°~360° respectively.

Part 4 steps

When measuring, adjust the position of the square or ruler first according to the situation of the measured part of the product, fasten them with the screws on the clamp, and then adjust the angle between the measuring surface of the base ruler and other relevant measuring surfaces. At this time, first loosen the nut on the brake head, move the main ruler for coarse adjustment, and then rotate the micro-movement device on the back of the fan-shaped plate for fine adjustment until the two measuring surfaces are closely attached to the measured surface. Then tighten the nut on the brake and take off the angle ruler for reading.

1. Measure the angle between 0°-50°

The square ruler and the ruler are all installed, and the measured part of the product is placed between the base ruler and the measuring surface of the ruler for measurement.

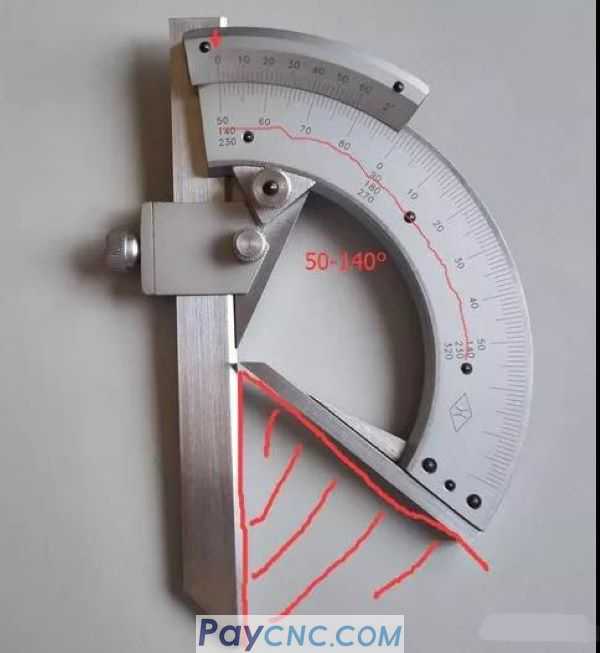

2. Measure the angle between 50°-140°

You can remove the square and install the ruler to connect it with the fan-shaped board. The measured part of the workpiece is measured between the base ruler and the measuring surface of the ruler. It is also not necessary to remove the square, just remove the ruler and the clip, and then pull the square to the bottom until the intersection of the short and long sides of the square is aligned with the sharp edge of the base ruler. Place the measured part of the workpiece between the base ruler and the measuring surface of the short side of the square for measurement.

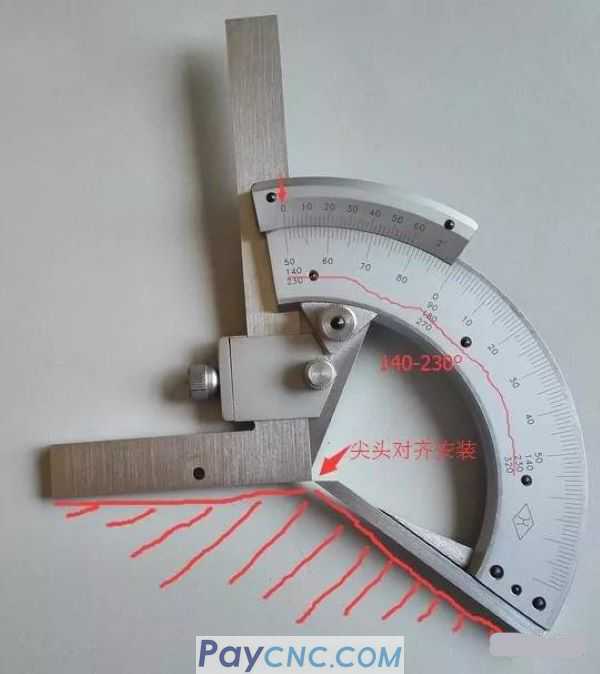

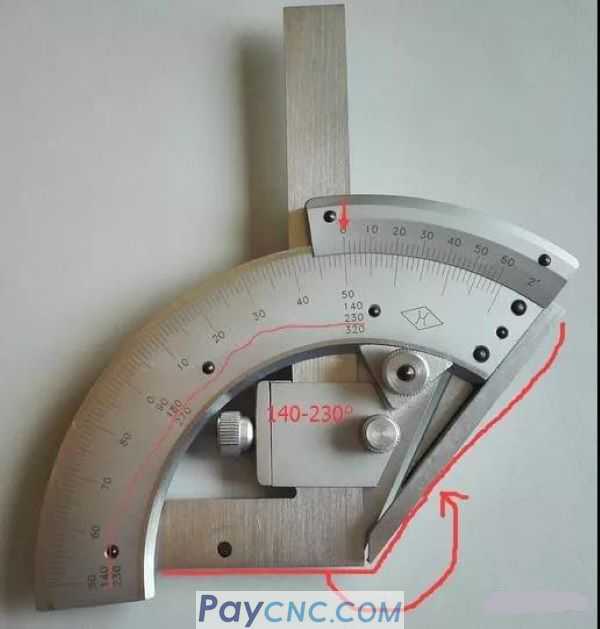

3. Measure the angle between 140°-230°

Remove the ruler and the clip, and only install the square, but push the square up until the intersection of the short and long sides of the square is aligned with the sharp edge of the base ruler. Place the measured part of the workpiece between the base ruler and the measuring surface of the short side of the square for measurement.

4. Measure the angle between 230°-320°

Remove all the square, ruler and clamps, leaving only the fan-shaped board and the main ruler (with base ruler). Place the measured part of the product between the base ruler and the measuring surface of the sector plate for measurement.

Part 5 reading method

The reading method of the universal angle ruler is the same as that of the vernier caliper. First read the angle before the zero line of the vernier, and then read the value of the angle "minute" from the vernier. The sum of the two is the angle value of the measured part.

Part 6 Maintenance and storage

Before use, first wipe the universal angle ruler clean, and then check whether the interaction of each part is stable and reliable, whether the reading after stopping does not move, and then zero; when measuring, loosen the nut on the brake and move the main ruler Make coarse adjustment of the seat, and then turn the handle on the back of the vernier to make fine adjustments until the two measuring surfaces of the angle ruler are in close contact with the working surface of the workpiece to be measured. Then tighten the nut on the brake to fix it, and the reading can be taken; after the measurement is completed, clean the universal angle ruler with gasoline or alcohol, dry it carefully with a clean gauze, coat it with anti-rust oil, and then put it into the box.

1. Types of universal angle ruler

2. Composition structure of 0-320° universal angle ruler

The 0-320° universal angle ruler is mainly composed of the following parts: square ruler, ruler, main ruler, vernier, base ruler, fan plate, brake head, clamp block

3. 0-50° measurement method

Install all parts of the square ruler and the ruler, and measure the object to be measured between the angle between the base ruler and the ruler

Four, 50-140° measurement method

Remove the square ruler, install the ruler, connect the ruler to the fan-shaped board, and place the measured object between the base ruler and the ruler for measurement.

Five, 140-230 ° measurement method

Remove the ruler and the clamp block, install only the ruler, and push the ruler up at the same time, so that the outer right angle of the ruler is aligned with the tip of the base ruler, and the measured object is placed between the angle between the base ruler and the square ruler. Take measurements.

Six, 230-320° measurement method

Remove all the square ruler, ruler and clamp block, leaving only the fan-shaped board and the main ruler (with a base ruler), and the measured object is placed between the base ruler and the fan-shaped board for measurement.

Seven, reading method

According to the measured angle range, the integer degree can be read from the largest integer division reached by the vernier 0 scale line on the main ruler from left to right, and the insufficient part is read by the scale on the vernier scale and the main ruler which is completely aligned.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|