Yesterday, a Weiyou who had been working on CNC cars for 2 years asked me, "How do I drive a figure 8 oil tank?"

The solution is simple:

The oil tank is a special application of the threading instruction.

The vehicle oil tank is divided into three situations:

1. Open oil groove---an oil groove with annular grooves (empty grooves) at both ends or ends.

2. Closed oil groove---an oil groove without annular grooves (empty grooves) at both ends.

3. Close the oil groove to the hole-one of the two intersections of the oil groove must pass through the oil inlet hole on the sleeve.

In the three cases, one step is more difficult than one step. Here I will discuss with you the programming of a closed narrow oil groove (a few strokes for the wide oil groove in the axial direction are enough.)

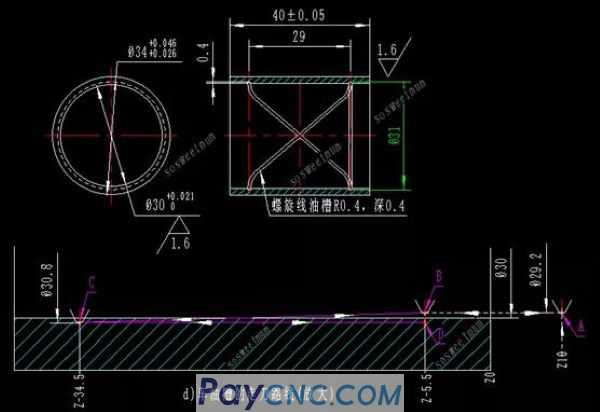

1. Workpiece drawings:

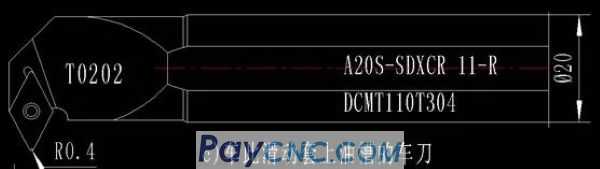

Second, the choice of tools

The shape of the cutter head is determined by the cross-sectional shape of the oil groove. If it is a circular arc profile, it is necessary to use a semi-circular turning tool to turn.

The oil groove of this workpiece has a radius of R0.4mm and a depth of 0.4mm, so one or two tool heads can be similar to the turning tool shown in the figure below.

Three, programming

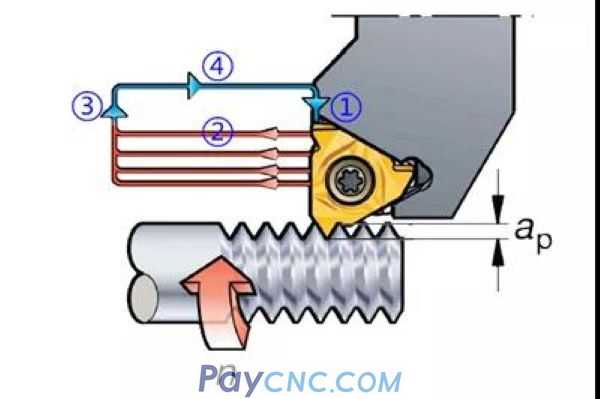

Let's start with the four actions of the threading tool path:

The four actions are:

① Cut in—②Thread cutting—③Retract tool—④Return

As shown below:

Then, the closed oil groove is an oil groove without annular grooves at both ends. (There are similar artifacts as shown in the figure below:)

Closed oil groove, that is, there is no annular groove at both ends of the workpiece, and it cannot be cut directly from the middle of the workpiece.

Solution:

Threads without advance and retreat grooves-oblique infeed is the key.

For the path of the diagonal cutting knife, you can see the picture below:

Description:

1. A-B-C line cuts into the workpiece obliquely;

2. Flat return to point D;

3. Ping back to point C;

4. Slanting out back to point B;

program:

N02 G54 S60 M03;

N03 T0202;

N04 G00 X100 Z10;

N05 X29.2; (Arrival at point A)

N06 Z-5.5; (Arrival at point B)

N07 G32 X30.8 Z-34.5 F58; (oblique entry to reach point C)

N08 Z-5.5; (return to point D)

N09 Z-34.5; (Go flat and return to point C)

N10 X29.2Z-5.5; (Exit diagonally back to point B)

N11G00X29.2;

N12G32X30.8Z-34.5 F58 Q180000; (the other circle goes obliquely to point C)

N13 Z-5.5; (return to point D in another lap)

N14 Z-34.5; (the other lap goes back to point C)

N15 X29.2Z-5.5; (Another circle slant out and return to point B)

N16 G00 Z10;

N17 X150 Z200 M05;

N18 M30;

Description:

Section N07 is a half-turn right-handed spiral groove for the car, and section N12 is a half-turn left-handed spiral groove for the car. The figure-eight oil tank is half-turn back and forth, so the pitch is 58mm instead of 29mm on the drawing.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|