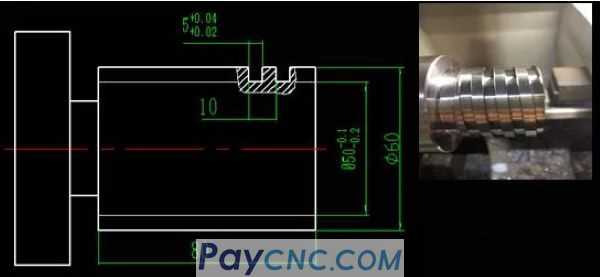

Example of using "borrowing tool method" to write rectangular thread program

Specifically broken down into two parts:

1. "Layering" in the X direction

2. "Layering" in the Z direction

1. X-direction layering

If the outer circle of the workpiece is D60 and the bottom diameter is D50, the program is relatively simple, so I won’t repeat it. Some programs are as follows:

#1=60

N05#1=#1-0.4

IF[#1LE50]THEN#1=50

...

…(The threading section is omitted)…

...

IF[#1 GT 50] GOTO05 (If you don’t have a car with a bottom diameter of 50, go back and continue the car)

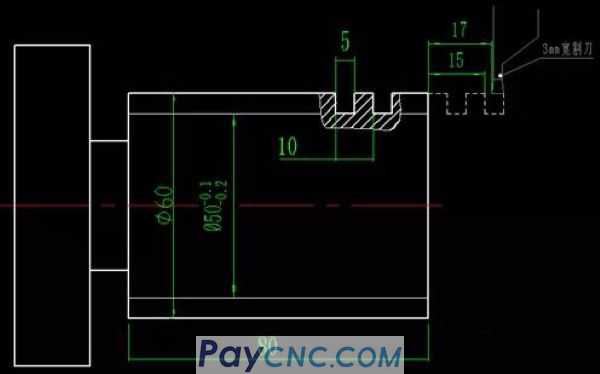

Second, Z-direction stratification

If the starting point of the thread cycle z of the 3mm cutter is set at a point outside the workpiece, part of the program is as follows:

#2=17.5

N08#2=#2-0.5;

IF[#2LE15]THEN#2=15

...

…(The threading section is omitted)…

...

IF[#2 GT 15] GOTO08;

Is it simple? It is exactly the same as the above X-layered program, and thus completed the borrowing in the Z direction.

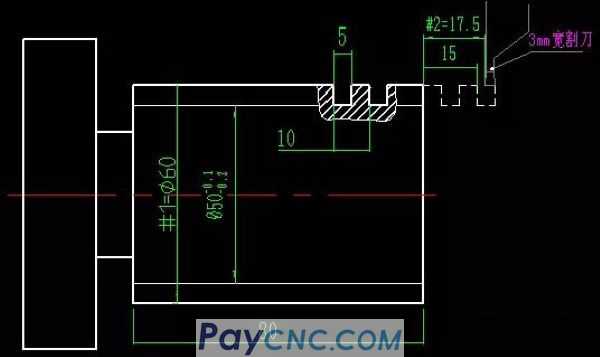

At this point in the analysis, if you have a clearer mind, I will directly go to the program, as follows:

%

O16 (Use grooving tool, turning saw type thread program)

N01 G54 S600 M03; (Set coordinate system, specify spindle speed, spindle forward rotation)

N02 T0101; (tool location number and tool compensation number)

N03 G00 X150 Z200; (rapidly reach the total starting point)

N04 #1=60; (#1 represents the X command value of each layer of the car, assign #1=60 to represent the value of the 0 layer of the car)

N05#2=[17+0.5] (#2 represents the Z command value of each tool of the lathe, and 17.5 represents the value of the 0 layer of the lathe)

N06#1=#1-0.4; (Calculate the depth of the knife in X direction)

N07 IF[#1LE 50]THEN#1=50 (to prevent overcutting in X direction)

N08 G00X70 (knife lift)

N09 #2=#2-0.5; (Calculate Z-direction tool borrowing value)

N10IF[#2LE15]THEN#2=15 (to prevent over-cutting in Z direction)

N11 G00 Z#2 (Z direction reaches the starting point of the thread cycle of the turning tool)

N12 G00 X#1 (The X direction reaches the starting point of the thread cycle of the turning tool)

N13 G32 Z-85 F10; (one cut)

N14 IF[#2 GT 15]GOTO 08; (If there is no car to the left border, go back up and continue the car)

N15 IF[#1 GT 50]GOTO 05 (If you don’t reach the bottom diameter of the thread, go back and continue the car)

N16 G00 X150

N17 Z200 M05;

N18 M30;

%

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|