1. Return to zero (return to machine origin)

Before tool setting, the zero return (return to the machine origin) operation must be performed so as to clear the coordinate data of the last operation. Note that the X, Y, and Z axes need to be zeroed.

2. Spindle forward

In the "MDI" mode, the spindle rotates forward by inputting the command code and maintains a medium rotation speed. Then change to the "handwheel" mode, and move the machine tool by switching the adjustment rate.

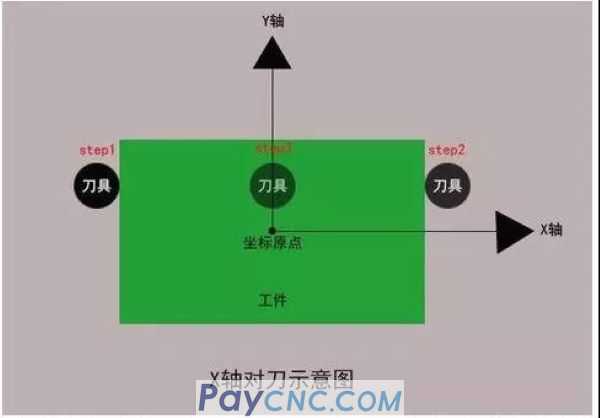

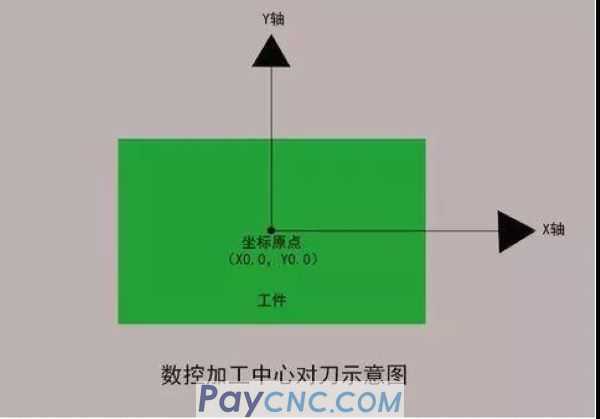

3.X-direction tool setting

Gently touch the tool on the right side of the workpiece to clear the relative coordinates of the machine tool; lift the tool in the Z direction, then move the tool to the left side of the workpiece, and move the tool and the workpiece down to the same height along Z. Gently touch, lift the tool, write down the X value of the relative coordinate of the machine tool, move the tool to half of the relative coordinate X, write down the X value of the absolute coordinate of the machine tool, and press (INPUT) to enter the coordinate system. .

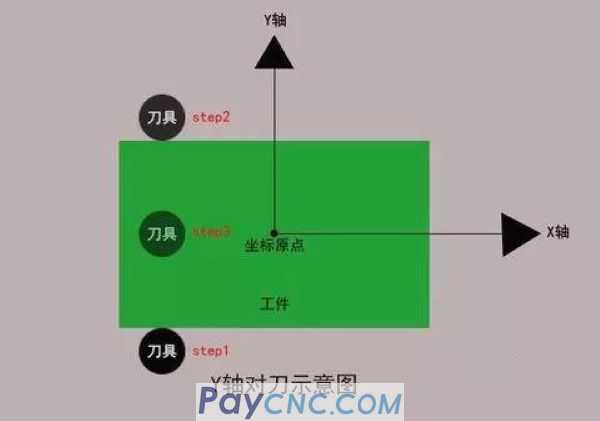

4. Y-direction tool setting

Gently touch the tool in front of the workpiece to clear the relative coordinates of the machine tool; lift the tool in the Z direction, and then move the tool to the back of the workpiece, and move the tool and the workpiece down to the same height along Z. Gently touch, lift the tool, record the Y value of the relative coordinate of the machine tool, move the tool to half of the relative coordinate Y, record the Y value of the absolute coordinate of the machine tool, and press (INPUT) to enter the coordinate system. .

5. Z-direction tool setting

Move the tool to the surface of the workpiece to be zero in the Z direction, slowly move the tool to lightly touch the upper surface of the workpiece, write down the Z value in the coordinate system of the machine tool at this time, and press (INPUT) to input Just in the coordinate system.

6. Spindle stall

Stop the spindle first, move the spindle to a suitable position, call the processing program, and prepare for formal processing.

How does the machining center produce and process easily deformable parts?

For parts with lighter weight, poor rigidity, and weak strength, they are susceptible to stress and thermal deformation during processing, and the high processing scrap rate leads to a substantial increase in costs. For such parts, we must first understand the causes of deformation:

Forced deformation:

Such parts have thin walls. Under the action of clamping force, different thicknesses are likely to occur in the machining and cutting process, and the elasticity is poor, and the shape of the parts is difficult to recover by themselves.

Thermal deformation:

The texture of the workpiece is light and thin, and due to the radial force during the cutting process, the workpiece will be heated and deformed, which will make the size of the workpiece inaccurate.

Vibration deformation:

Under the action of radial cutting force, parts are prone to vibration and deformation, which affect the dimensional accuracy, shape, position accuracy and surface roughness of the workpiece.

Processing method of easily deformable parts:

Easily deformable parts represented by thin-walled parts can be processed with a small feed rate and high cutting speed, which can reduce the cutting force on the workpiece during processing, and at the same time make most of the cutting heat fly away from the chips of the workpiece at high speed. Take it away, thereby reducing the temperature of the workpiece and reducing the thermal deformation of the workpiece.

Why do machining center tools need to be passivated?

CNC tools are not as fast as possible, so why do they need to be passivated? In fact, tool passivation is not what everyone understands literally, but a way to improve tool life. Improve the quality of cutting tools through processes such as leveling, polishing, and deburring. This is actually a normal process after the tool is finely ground and before the coating.

The tool will be sharpened by a grinding wheel before the finished product, but the sharpening process will cause different degrees of microscopic gaps. When the machining center is performing high-speed cutting, the micro-notch will easily expand, which will accelerate the wear and damage of the tool. Modern cutting technology has strict requirements on the stability and precision of the cutting tool. Therefore, the CNC cutting tool must be passivated on the cutting edge before coating to ensure the firmness and service life of the coating. The benefits of tool passivation are:

1. Resistance to physical wear of the tool

During the cutting process, the tool surface will be gradually worn away by the workpiece, and the cutting edge is also prone to plastic deformation under high temperature and high pressure during the cutting process. The passivation treatment of the tool can help the tool increase its rigidity and prevent the tool from losing its cutting performance prematurely.

2. Maintain the finish of the workpiece

Burrs on the cutting edge of the tool will cause the tool to wear, and the surface of the machined workpiece will become rough. After passivation treatment, the cutting edge of the tool will become very smooth, the phenomenon of chipping will be reduced correspondingly, and the surface finish of the workpiece will be improved.

3. Convenient for groove chip removal

Polishing the tool groove can improve the surface quality and chip removal performance. The smoother the surface of the groove, the better the chip removal, and a more consistent cutting process can be achieved. After the CNC tool of the machining center is passivated and polished, there will be many small holes on the surface. These small holes can absorb more cutting fluid during processing, which greatly reduces the heat generated during cutting, which greatly improves the cutting process speed.

How does the machining center reduce the surface roughness of the workpiece?

Rough surface of parts is one of the common problems of CNC machining center, which directly reflects the processing quality. How to control the surface roughness of parts processing, we must first in-depth analysis of the reasons for the surface roughness, including: tool marks caused by the milling process; thermal deformation or plastic deformation caused by cutting separation; tools and machined surfaces Friction between.

When selecting the surface roughness of the workpiece, it should not only meet the requirements of the surface function of the part, but also consider the economic rationality. On the premise of satisfying the cutting function, a larger surface roughness reference value should be selected as far as possible to reduce production costs. As the executor of the cutting machining center, the tool should pay attention to the daily maintenance and timely grinding to avoid the unqualified surface roughness caused by the blunt tool.

What should I do after the machining center finishes its work?

The processing procedures of the traditional machine tools of the machining center are generally the same. The main difference is that the machining center completes all the cutting procedures through a single clamping and continuous automatic processing. Therefore, the machining center needs to perform some operations after completing the CNC machining. Aftermath work".

▲Machine tool inspection and maintenance

1. Carry out cleaning treatment. After the machining center completes the cutting task, it must promptly remove the chips, wipe the machine god, and use the machine tool to keep the environment clean.

2. For inspection and replacement of accessories, first pay attention to checking the oil wiping plate on the guide rail. If it is worn out, replace it in time. Check the state of lubricating oil and coolant. If turbidity occurs, replace it in time, and add it if the water level is below the scale.

3. The shutdown procedure should be standardized, and the power supply on the machine operation panel and the main power supply should be turned off in sequence. In the absence of special circumstances and special requirements, the principles of first zero return, manual, jog, and automatic should be followed. The machining center should also run at low speed, medium speed, and then high speed. Low-speed and medium-speed running time shall not be less than 2-3 minutes before starting to work without abnormal conditions.

4. Standardized operation, do not knock, correct or correct the workpiece on the chuck or at the center. The workpiece and the tool must be clamped before proceeding to the next operation. The insurance and safety protection devices on the machine tool must not be disassembled or moved arbitrarily. The most efficient processing is actually safe processing. As an efficient processing equipment, the operation of the processing center when shutting down must be reasonable and standardized. This is not only the maintenance of the current completed process, but also the preparation for the next start.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|