Stainless steel (Stainless Steel) is the abbreviation of stainless and acid-resistant steel. It is called stainless steel that is resistant to weak corrosive media such as air, steam, and water, or is stainless steel; and chemically resistant to chemical corrosion media (acid, alkali, salt, etc.) Corrosion steel is called acid-resistant steel.

Stainless steel refers to steel that is resistant to weak corrosive media such as air, steam, and water, and chemically corrosive media such as acid, alkali, and salt. It is also called stainless acid-resistant steel. In practical applications, steel that is resistant to corrosion by weak corrosive media is often called stainless steel, and steel that is resistant to chemical media is called acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to corrosion by chemical media, while the latter is generally non-corrosive. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel.

Common classification:

Usually divided into metallographic organization:

Generally, according to the metallographic structure, ordinary stainless steel is divided into three categories: austenitic stainless steel, ferritic stainless steel, and martensitic stainless steel. Based on these three basic metallographic structures, for specific needs and purposes, dual-phase steels, precipitation hardening stainless steels, and high-alloy steels with an iron content of less than 50% have been derived.

1. Austenitic stainless steel.

The matrix is mainly austenitic structure (CY phase) with face-centered cubic crystal structure, non-magnetic, stainless steel that is strengthened by cold working (and may lead to certain magnetic properties). The American Iron and Steel Institute uses numbers in the 200 and 300 series, such as 304.

2. Ferritic stainless steel.

The matrix is mainly a ferrite structure with body-centered cubic crystal structure (phase a), which is magnetic and generally cannot be hardened by heat treatment, but can be slightly strengthened by cold working. The American Iron and Steel Institute uses 430 and 446 as the label.

3. Martensitic stainless steel.

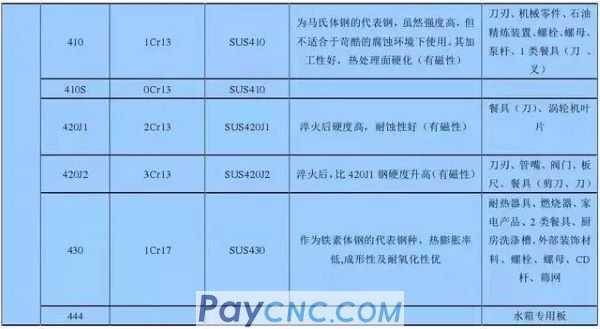

The matrix is a martensite structure (body-centered cubic or cubic), a stainless steel with magnetic properties and its mechanical properties can be adjusted by heat treatment. The American Iron and Steel Institute is marked with 410, 420 and 440 numbers. Martensite has an austenite structure at high temperatures, and when cooled to room temperature at an appropriate speed, the austenite structure can be transformed into martensite (that is, hardened).

4. Austenitic-ferritic (duplex) stainless steel.

The matrix has a two-phase structure of austenite and ferrite. The content of the lesser phase matrix is generally greater than 15%. It is a stainless steel that can be strengthened by cold working. 329 is a typical duplex stainless steel. Compared with austenitic stainless steel, dual-phase steel has higher strength, and has significantly improved resistance to intergranular corrosion, chloride stress corrosion and pitting corrosion.

5. Precipitation hardening stainless steel.

A stainless steel whose matrix is austenite or martensite and can be hardened by precipitation hardening treatment. The American Iron and Steel Institute uses the 600 series of numbers, such as 630, which is 17-4PH.

Generally speaking, in addition to alloys, the corrosion resistance of austenitic stainless steel is relatively excellent. In a low corrosive environment, ferritic stainless steel can be used. In a mildly corrosive environment, if the material is required to have high For strength or high hardness, martensitic stainless steel and precipitation hardening stainless steel can be used.

Features and uses

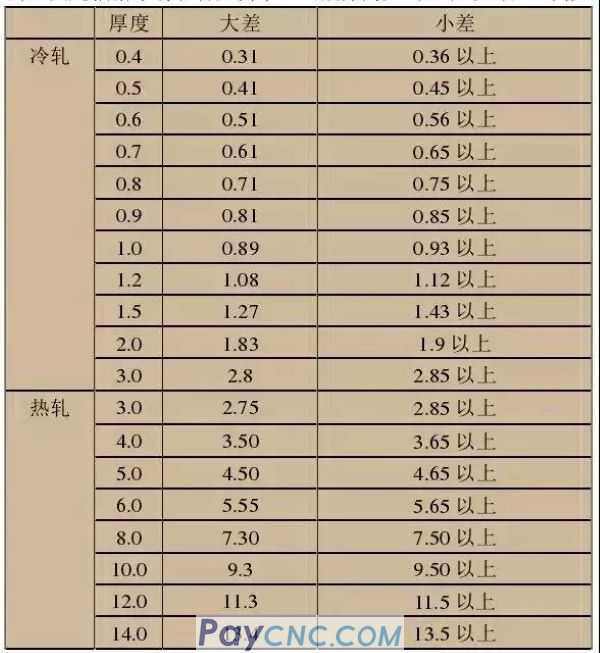

Thickness distinction

1. During the rolling process of the steel mill machinery, the rollers are heated and slightly deformed, which leads to deviations in the thickness of the rolled plates. Generally, the thickness of the middle and the sides are thin. When measuring the thickness of the board, the state stipulates that the middle part of the board head should be measured.

2. The reason for the tolerance is that according to the market and customer needs, it is generally divided into large tolerance and small tolerance: for example

What kind of stainless steel is not easy to rust?

There are three main factors affecting stainless steel corrosion:

1. The content of alloying elements.

Generally speaking, the chromium content of 10.5% steel is not easy to rust. The higher the content of chromium and nickel, the better the corrosion resistance. For example, the content of nickel for 304 material is 8-10%, and the content of chromium reaches 18-20%. Such stainless steel will not rust under normal circumstances.

2. The smelting process of the manufacturer will also affect the corrosion resistance of stainless steel.

A large stainless steel plant with good smelting technology, advanced equipment and advanced technology can guarantee the control of alloying elements, the removal of impurities, and the control of the cooling temperature of the billet, so the product quality is stable and reliable, the internal quality is good, and it is not easy to rust. On the contrary, some small steel mills have backward equipment and technology. During the smelting process, impurities cannot be removed, and the products produced will inevitably rust.

3. External environment, dry and ventilated environment is not easy to rust.

However, the air humidity is high, continuous rainy weather, or the environment with high pH in the air is easy to rust. 304 stainless steel, if the surrounding environment is too bad, it will rust.

How to deal with stainless steel rust spots?

1. Chemical methods

Use pickling paste or spray to assist the re-passivation of the rusted parts to form a chromium oxide film to restore the corrosion resistance. After pickling, in order to remove all contaminants and acid residues, it is very important to rinse properly with clean water. After all treatments, re-polishing with polishing equipment and sealing with polishing wax. For those with slight rust spots, you can use a 1:1 gasoline and engine oil mixture to wipe off the rust spots with a clean cloth.

2. Mechanical method

Sandblasting, using glass or ceramic particle shot blasting, annihilation, brushing and polishing. It is possible to use mechanical methods to wipe off the contamination caused by previously removed materials, polishing materials or oblivious materials. All kinds of pollution, especially foreign iron particles, can become a source of corrosion, especially in humid environments. Therefore, mechanically cleaned surfaces should be properly cleaned under dry conditions. The use of mechanical methods can only clean the surface, and cannot change the corrosion resistance of the material itself. Therefore, it is recommended to re-polishing with polishing equipment after mechanical cleaning and sealing with polishing wax.

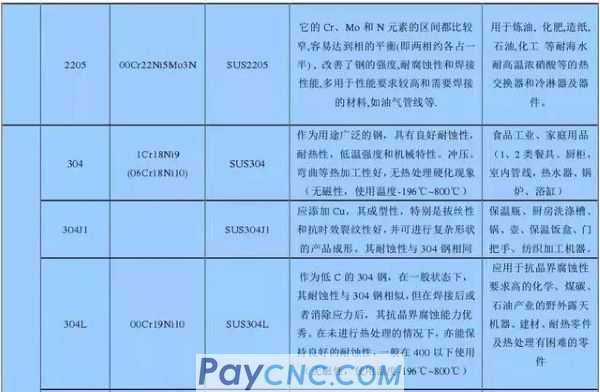

Commonly used stainless steel grades and performance of instruments

1. 304 stainless steel. It is one of the most widely used austenitic stainless steels. It is suitable for the manufacture of deep-drawing forming parts and acid pipes, containers, structural parts, various instrument bodies, etc. It can also manufacture non-magnetic, low-temperature equipment and part.

2. 304L stainless steel. In order to solve the problem of the severe intergranular corrosion tendency of 304 stainless steel due to the precipitation of Cr23C6, the ultra-low carbon austenitic stainless steel developed, and its sensitized state of intergranular corrosion resistance is significantly better than that of 304 stainless steel. Except for the slightly lower strength, other properties are the same as 321 stainless steel. It is mainly used for corrosion-resistant equipment and parts that cannot be solid-solution treated after welding, and can be used to manufacture various instrument bodies.

3. 304H stainless steel. The internal branch of 304 stainless steel has a carbon mass fraction of 0.04%-0.10%, and its high temperature performance is better than that of 304 stainless steel.

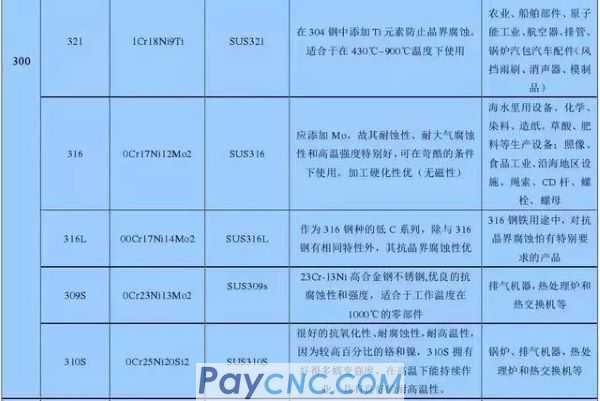

4. 316 stainless steel. Molybdenum is added to the 10Cr18Ni12 steel, so that the steel has good resistance to reducing media and pitting corrosion. In seawater and other various media, the corrosion resistance is better than 304 stainless steel, which is mainly used for pitting-resistant materials.

5. 316L stainless steel. Ultra-low carbon steel has good resistance to intergranular corrosion in the sensitized state, and is suitable for the manufacture of welded parts and equipment with thick cross-section dimensions, such as corrosion-resistant materials in petrochemical equipment.

6. 316H stainless steel. The internal branch of 316 stainless steel has a carbon mass fraction of 0.04%-0.10%, and its high temperature performance is better than that of 316 stainless steel.

7. 317 stainless steel. The resistance to pitting and creep is better than that of 316L stainless steel. It is used to manufacture petrochemical and organic acid corrosion resistant equipment.

8. 321 stainless steel. Titanium-stabilized austenitic stainless steel, adding titanium to improve intergranular corrosion resistance, and has good high-temperature mechanical properties, which can be replaced by ultra-low carbon austenitic stainless steel. Except for special occasions such as high temperature or hydrogen corrosion resistance, it is generally not recommended to use.

9. 347 stainless steel. Niobium-stabilized austenitic stainless steel, adding niobium to improve intergranular corrosion resistance. The corrosion resistance in acid, alkali, salt and other corrosive media is the same as that of 321 stainless steel. The welding performance is good. It can be used as a corrosion-resistant material and can be used as a corrosion-resistant material. Hot steel is mainly used in thermal power and petrochemical fields, such as making vessels, pipes, heat exchangers, shafts, furnace tubes in industrial furnaces, and furnace tube thermometers.

10. 904L stainless steel. Super completely austenitic stainless steel is a kind of super austenitic stainless steel invented by Finnish Outokumpu (OUTOKUMPU). Its nickel mass fraction is 24% to 26%, carbon mass fraction is less than 0.02%, and it has excellent corrosion resistance. It has good corrosion resistance in non-oxidizing acids such as sulfuric acid, acetic acid, formic acid, and phosphoric acid, as well as good crevice corrosion and stress corrosion resistance. It is suitable for sulfuric acid of various concentrations below 70°C, and has good corrosion resistance in acetic acid at any concentration and at any temperature and mixed acid of formic acid and acetic acid under normal pressure. The original standard ASMESB-625 put it into nickel-based alloy, and the new standard put it into stainless steel. China only has similar grades of 015Cr19Ni26Mo5Cu2 steel. The key material of a few European instrument manufacturers uses 904L stainless steel. For example, the measuring tube of E+H mass flowmeter uses 904L stainless steel, and the case of Rolex watches also uses 904L stainless steel.

11. 440C stainless steel. Martensitic stainless steel has the highest hardness among hardenable stainless steel and stainless steel, with a hardness of HRC57. Mainly used to make nozzles, bearings, valve cores, valve seats, sleeves, valve stems, etc.

12. 17-4PH stainless steel. Martensitic precipitation hardening stainless steel, with a hardness of HRC44, has high strength, hardness and corrosion resistance, and cannot be used at temperatures higher than 300°C. It has good corrosion resistance to the atmosphere and diluted acid or salt. Its corrosion resistance is the same as 304 stainless steel and 430 stainless steel. It is used to manufacture offshore platforms, turbine blades, valve cores, valve seats, sleeves, and valve stems. Wait.

In the instrument profession, combined with versatility and cost issues, the conventional austenitic stainless steel selection order is 304-304L-316-316L-317-321-347-904L stainless steel, of which 317 is less used, 321 is not recommended, and 347 is used In terms of high temperature and corrosion resistance, 904L is only the default material for some components of individual manufacturers, and 904L is generally not actively selected in the design.

In the design and selection of instruments, there are usually occasions where the material of the instrument is different from the material of the pipe, especially in high-temperature conditions. It is necessary to pay special attention to whether the choice of the material of the instrument meets the design temperature and design pressure of the process equipment or pipeline, such as pipeline For high-temperature chromium-molybdenum steel, and stainless steel is selected for the instrument, there may be a problem at this time, and you must consult the temperature and pressure gauge of the relevant material.

In the instrument design and selection, various systems, series, and grades of stainless steel are often encountered. The selection should be based on the specific process medium, temperature, pressure, stressed parts, corrosion, cost and other aspects.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|