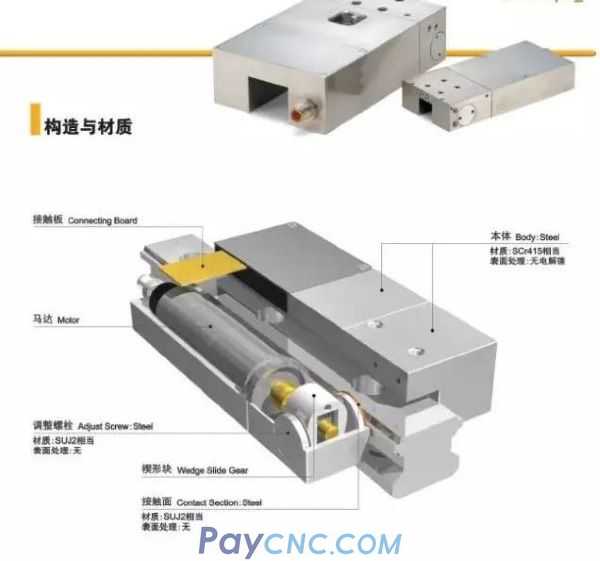

1. Structure and function

The duress device for the tumbling linear guide is composed of the main body of the duress, the driving element, and the coercive tissue. It is a high-performance functional component used in conjunction with the tumbling linear guide. The normally open type has the functions of fixing the table, precise positioning, avoiding vibration and improving rigidity; the normally closed type also has the effect of pressing the brake when the power is off.

2. Terminology

1. Normally open type: When air pressure or oil pressure is not supplied, the coercive tissue of the coercor is in a loose state.

2. Normally closed type: When air pressure or oil pressure is not supplied, the stressing organization of the coercor uses the effect of spring or screw to coerce the linear guide rail.

3. Persistence: The effect is in the direction of movement of the linear guide pair and the load in the vertical direction.

Persistence varies with the coefficient of static friction between the guide rail and the stress tissue. (The persistence in this product sample is the calculated value when the static friction coefficient is 0.1.)

4. Minimum operating pressure: the minimum pressure required for the normal use of the duress.

5. The highest operating pressure: the highest pressure promised during the normal use of the duress.

6. Maximum remaining pressure: The maximum remaining pressure allowed by the hydraulic pressure device after stopping the fuel supply.

7. Device pad: a pad that makes the height of the coercion device consistent with the height of the rolling linear guide pair.

8. Air consumption: the amount of air required for one stroke of the duress.

9. Hydraulic oil consumption: the amount of oil required for one stroke of the damper.

10. Response time:

Response time of the normally-open duress: when the system announces the signal to start supplying gas and oil, it is the time to start supplying gas and oil to the duress.

Normally closed duressor response time: when the system announces the signal to stop gas and oil supply, it is the time to stop the gas and oil supply to the duress.

11. Respond to the moment:

The response time of the normally-open duress: from the beginning of supplying air and oil to the duress, to the moment of clamping the linear guide.

The response time of the normally closed duress: from the suspension of the gas and oil supply to the duress to the moment when the linear guide is clamped.

Three, type

1. Air pressure normally open series

1) Features

a. Through the principle of wedge block expansion, pressure is used to complete the stress.

b. Small structure and strong persistence.

c. Novel planning to avoid rigid impact when tightening.

d. The installation is convenient, and it is directly connected with the workbench without changing the workbench scale.

e. Precise positioning, suitable for pneumatic clamping of motion shafts.

Note: The air pressure corresponding to the persistence in the table is 0.6MPa; the persistence is proportional to the pressure within the operating pressure range.

2. Air pressure normally closed with brake type series

1) Features

a. Use the spring energy storage effect on the wedge to complete the duress and brake.

b. Use air pressure to avoid duress.

c. Quick response to avoid falling and bumping of the vertical axis, which has the effect of maintaining the machine tool.

d. Convenient installation, directly connected with the workbench, without changing the workbench scale.

e. High positioning accuracy, suitable for fixed processing base workbench.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|