Customer request

The robot replaces the people to sort and choose the glass tube to realize the automatic and stable production of reciprocating and fast handling sorting;

The robot grabs the glass tube from the conveyor line and puts it into the shaping cutter;

Production speed: 0.8 seconds / piece, 24 hours continuous production.

solution

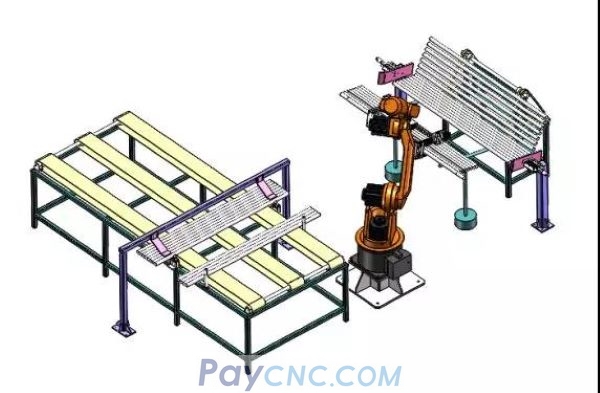

Adopting one RB20 handling robot, with the pipe cutting conveyor line, one sorting and positioning device, and one feeding conveyor to complete the automatic trimming, sorting and high-temperature forming manufacturing process of the neon tube;

The robot hand grip adopts a flexible design. For the production of different pipe diameters, the clamping force and position can be adaptively adjusted, and it is compatible with all workpieces to capture 20-30 pieces of lamps and tubes at a time.

The sorting and positioning device is designed with automatic sorting lamp, shaping positioning and sorting function to prevent pinching and falling abnormalities;

Application effect

The robot replaces the manual and can continue to work 24 hours a day to stabilize the work task;

The glass manufacturing industry is a dangerous industry, especially high-temperature and high-efficiency production, glass shards and dust, which have a certain impact on workers' working environment and physical and mental health. Robots can avoid various accidents and provide production efficiency. ;

Experts believe that the application of robots in the glass manufacturing industry is the trend of the times, which is not only the driving force of the market, but also the upgrading of production technology.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|