|

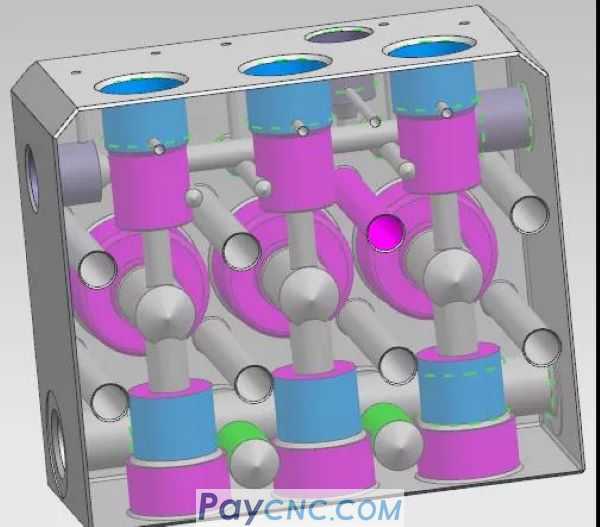

The processing material is 316 forged steel, which is processed according to the drawings (processing ¢3, 5.5, 6, 8, 8.5, 10.5, 12, 15, 18 and other deep holes, thread, fine holes and other features).

solution

Draw 3D models according to customer drawings, formulate processing strategies, and process processing procedures;

Make one sample in six processes;

It is recommended that the processing machine be equipped with a water outlet function in the spindle center and a set of 4th axis rotating worktable with hydraulic brake;

For mass production, use a special center water outlet drill for stainless steel for drilling. ¢15 and 18 use U drill for drilling, G3/8, G1/2, M20x1.5, M27x2 use thread milling cutter (milling cutter) for milling, some of the features in the figure Processing with forming knife;

The shape is processed with hexahedron and chamfer by ordinary face milling;

The front (large hole surface), left and right sides, using a VMC850L machine tool + 4th axis rotating table, one clamping, 3 sides in one process;

On the back, upper and lower sides, a VMC850L machine tool + 4th-axis rotating table is used for one-time clamping and three faces are processed in one process.

Processing effect

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|