The method of controlling the spindle rotation speed is called spindle speed control (the spindle rotates through a speed command), and the control of the spindle position is called spindle contour control (the spindle rotates through a movement command). The speed and position control function of the spindle is the CS contour control function. It can perform indexing and rigid tapping, and can interpolate and process contour curves with other feed axes.

Set the current operation authority to the machine manufacturer level.

There will be corresponding comments when the cursor moves to the corresponding option during the debugging setting process.

01CS axis contour control function debugging method

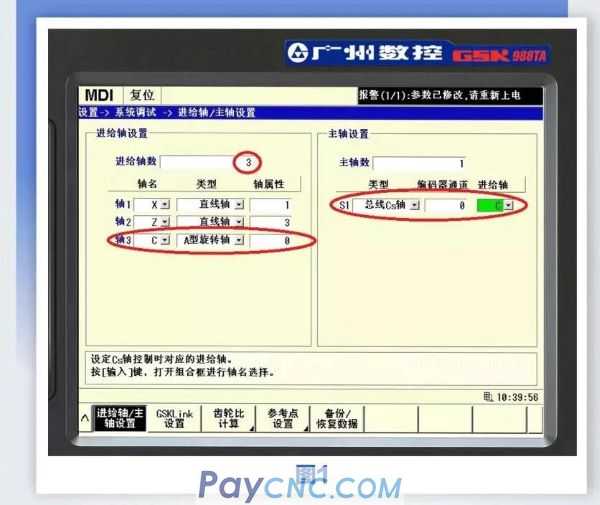

[Settings]-[System debugging]-[Feed axis/spindle setting]. Set it as shown in Figure 1.

[System]-[GSKLink]-[Communication]-[System Settings]. Set the GSKLink-CS axis logic ID number. Consistent with servo parameter PA156.

Power on the system again. Then modify the parameters according to the following figure:

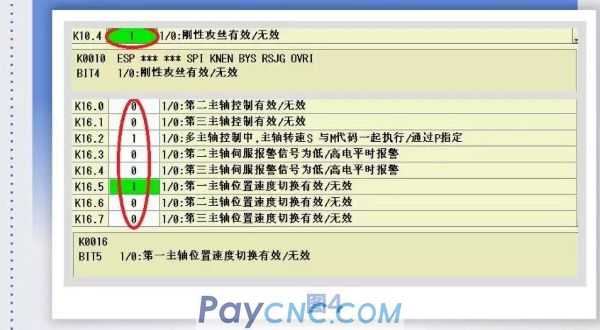

【System parameters】.

Ladder diagram PLC data

[System]-[Ladder Diagram]-[PLC Data]-[K Setting]

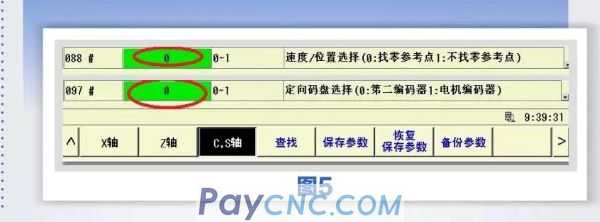

Set servo parameters

[System]-[GSKLink]-[Servo]-[Servo parameters]-[C, S axis]. Set according to the design requirements of the machine tool. The spindle switch and the CS axis contour control need to find the zero reference point and modify PA88 to "0". After modifying the parameters, press "Save parameters".

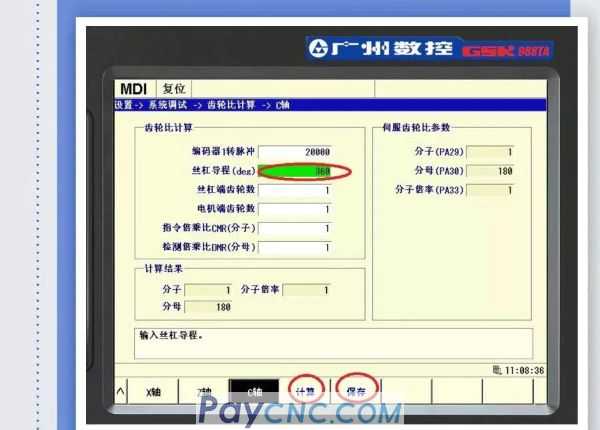

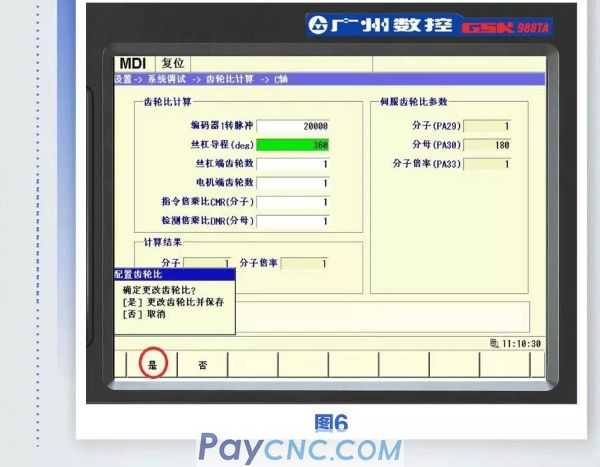

02Set C-axis electronic gear ratio

[Settings]-[System debugging]-[Gear ratio calculation]. Set the screw lead to "360" and press "Calculate" to save the calculated result to the servo.

03CS axis speed/position switching control

In the MDI mode, press the program key to execute the M14 command. If the system does not generate an alarm, it means it has successfully switched to the position control mode, and then execute G01H3600. If the spindle rotates ten times and stops at the starting point just now, verify that the gear ratio is set correctly; M15 command, the system does not generate an alarm, it means that it has successfully switched to speed control mode, and then executes M15 command, the system does not generate an alarm, it means it has successfully switched to speed control mode, and then executes M3 S500, the spindle rotates normally, indicating that the CS axis function has been The debugging is normal.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|