Brief introduction to FANUC second reference point setting

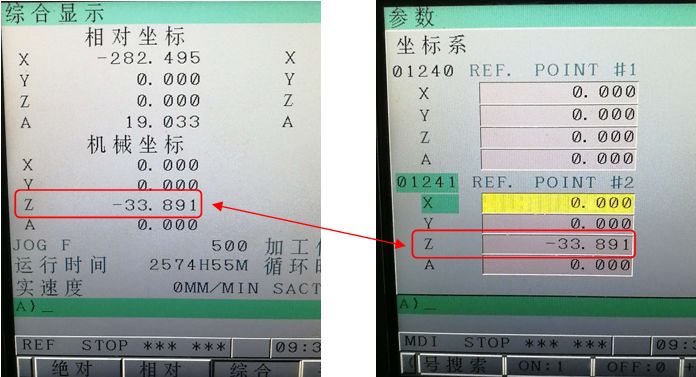

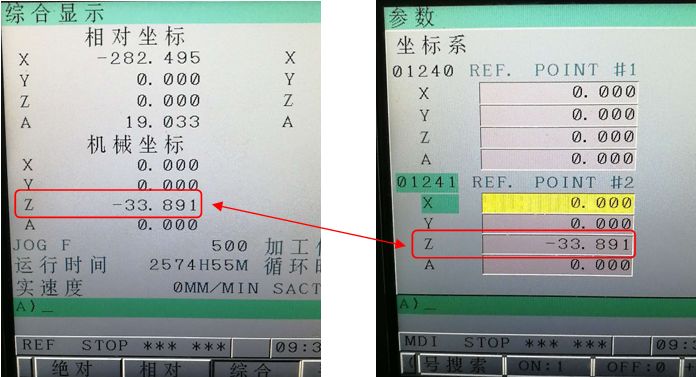

No.1240: Coordinate value of the first reference point in the mechanical coordinate system

No.1241: Coordinate value of the second reference point in the mechanical coordinate systemNo.1242: Coordinate value of the third reference point in the mechanical coordinate systemNo.1243: Coordinate value of the fourth reference point in the mechanical coordinate system

Among them, parameter No.1240 is protected, and the machine tool returns to the reference point by returning to the coordinate values under this parameter. We can set the mechanical coordinate values in parameters No.1241, No.1242, and No.1243. When using them, we can call the second reference point, the third reference point, and the fourth reference point through G30. The first reference point is called through G28.

For example: G30 P2 X0 Y0 Z0; when executing this instruction, the machine tool will go to the XYZ coordinate value in parameter No.1241.

If you need to set the third reference point, the programming method is: G30 P3 X0 Y0 Z0; execute this command, the machine tool will move to the XYZ coordinate value in parameter No.1242.

The second, third and fourth reference points can be used as tool change points in the tool magazine or fixed points for robot to pick up and place parts. When the position needs to be changed, modify the XYZ coordinate values in parameters 1241~1243. |