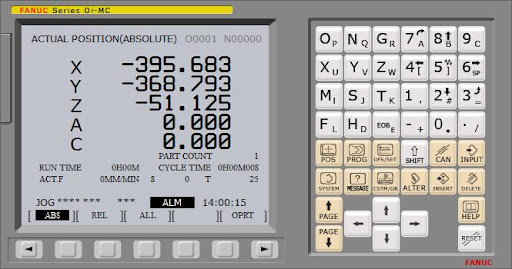

Fanuc 0i-MC Initial fault site: The machine tool occasionally had Z-axis 436 and 430 alarms during operation.

Fault resolution process:

After arriving at the site, the machine tool started up normally and moved all axes normally.

Checking the system alarm record, there was a Z-axis 436 alarm. Continue to move the Z-axis and check that the motor had no vibration. A few minutes later, Z-axis 430 and 436 alarms appeared.

Check the motor power cable to confirm that it was normal and check the relevant parameter settings without finding any major problems. Replace the Z-axis encoder, the above fault is eliminated, and the machine tool is normal.

However, after the machine tool worked normally for about 2 hours, the Z-axis occasionally had 410 or 411 alarms. Check the feedback cable and Z-axis brake voltage of the Z-axis. Check the Z-axis servo amplifier and Z-axis motor and no abnormalities were found.

Continue to move the Z-axis slowly with the handwheel. Careful observation found that the Z-axis had a short stop phenomenon when moving before the alarm. Continue to check the mechanical part to confirm that it is normal. It is suspected that there is a problem with the brake part of the Z-axis motor.

The 24V brake power supply was monitored with an oscilloscope and found that the voltage occasionally dropped below 1V, and then returned to normal in a short time.

After checking the peripheral circuit, it was found that the printed circuit board of the 24V power supply had been carbonized, resulting in the 24V voltage being intermittent. After the abnormal 24V was replaced with a printed circuit board of the same specification, the machine tool returned to normal. |