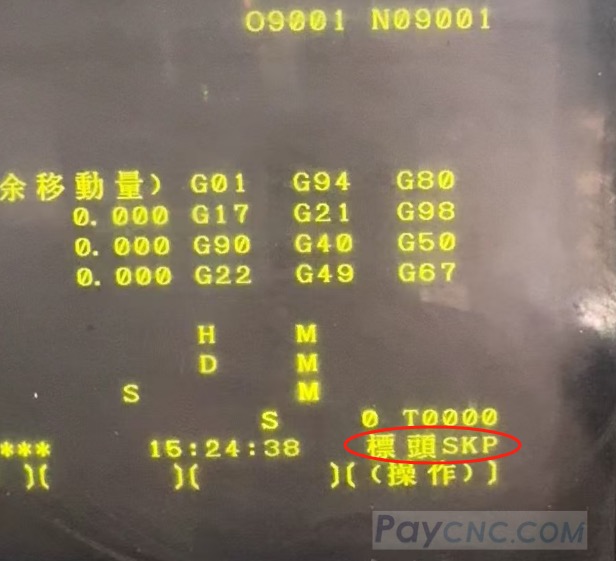

Fault of "header SKP" flashing on CNC vertical lathe

Fault phenomenon: The CNC vertical lathe adopts FANUC 0T CNC system. When the EDIT/AUTO mode is selected, the "header SKP" on the machine display flashes continuously and cannot run normally. Only by pressing the RESET key can it switch to other modes (such as MDI mode), and there is no such fault phenomenon in other modes.

Fault analysis and solution: The "header SKP" flashes on the machine tool. Generally, it is because the processing program is being transmitted through the RS232 communication interface. When the program transmission is completed, the machine tool can return to normal. However, the processing program of this machine tool has been transmitted and is not in the program transmission state at all. The parameters related to the CNC system, computer and communication (such as baud rate, data bit, stop bit, etc.) are all normal. In addition to eliminating common fault causes, the machine tool was set to MDI mode to check whether the program could be manually input normally. It was found that when the G code (such as G01) was input and the "input" button was not pressed, the G code had been entered into the system. The cause of the fault may be related to the "input" button. Then the button was removed and water droplets were found inside. At the same time, its resistance value was measured to be about 95Ω (the button was in the normally open state), close to the "short circuit" state. The normal resistance value should tend to infinity, close to the "open circuit" state. After cleaning and drying the button, reinstall it for testing. No "header SKP" flashed, and the fault was eliminated. In order to clarify the root cause of the fault, select EDIT/AUTO mode and press the "input" button to reproduce the fault (this phenomenon is rarely noticed by operators and maintenance personnel), further verifying that the fault was caused by abnormal buttons.

Summary: The special feature of this fault is that it seems to be a communication fault, but it is actually a hardware fault (water ingress and short circuit in the key). This type of fault is relatively rare and very confusing. When faced with this type of fault, we must first understand the process and principle that caused the fault, and then try to start from other aspects related to the fault, and then find a breakthrough in fault diagnosis. For example: in this example, verify whether the G code can be input normally in the MDI state, so as to find out the "input" key fault. |