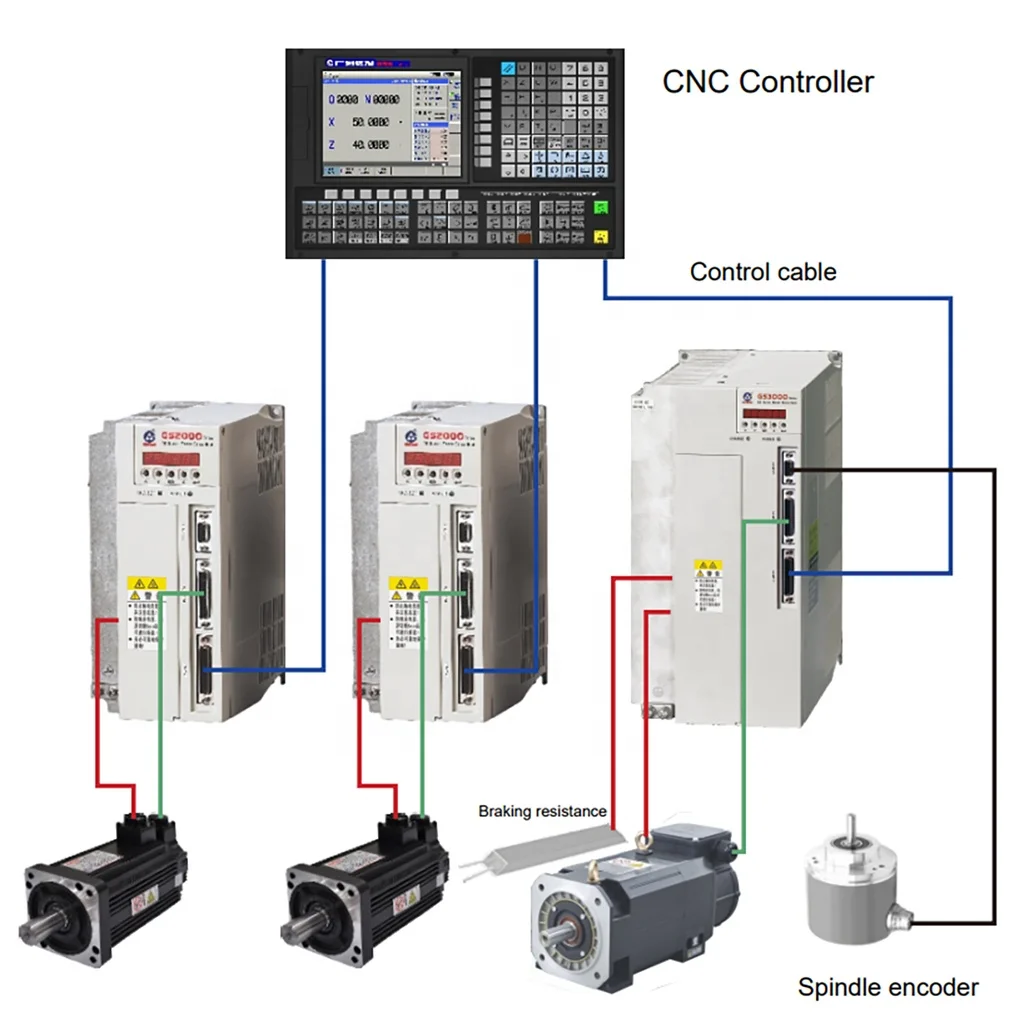

Since the GS series AC servo drive unit came out in 2011, relying on GSK advanced technology and strict production process, with superior product performance and high reliability, it can adapt to and give full play to the excellent performance of economical and popular CNC machine tools, and has won long-term success. favored by users. Adapt to three power levels, 45KW maximum output power, to meet the various needs of users.

Adopt D-SUB socket, support digital pulse, analog voltage input, the first and second position feedback input are suitable for incremental encoder, no bus interface, suitable for economical and popular numerical control system.

| Drive model |

GS-N |

| communication bus |

No bus |

| Working mode |

Test run, jog, speed, position, internal speed, speed/position switching |

| Position control |

Pulse + direction, CCW pulse + CW pulse, A/B phase quadrature pulse three pulse differential signal input |

| Maximum pulse frequency: 1MHz |

| Position command electronic gear ratio: (1~32767)/(1~32767) |

| Speed control |

Speed command input: -10V~+10V or 0V~10V |

| Speed command electronic gear ratio: (1~32767)/(1~32767) |

| Speed range: 1~5000rpm (feed servo) |

Orientation function: 4-point orientation can be realized, and 4 orientation angles set by parameters can be selected by external

input signal |

| First position feedback |

A/B/Z three pairs of differential signal input, feed servo adaptation 5000p/r, 2500p/r |

| Second position feedback |

Feed servo optional interface, A/B/Z three pairs of differential signal input, suitable for 1024~8192p/r incremental encoder. |

| Position feedback output |

1:1 output A/B/Z differential signal based on the first or second position feedback input signal |

| DI/DO |

Input 11 points: servo enable, CCW start, CW start, speed/position switching, orientation start, orientation/speed selection |

1. Orientation/speed selection input; 2. Second speed gain selection, spindle clamping interlock signal, zero-speed clamping,

alarm reset |

Output 7 points: ready, zero speed output, position and speed arrival, orientation completion, alarm output, speed position

status, encoder zero point (Z pulse) |

| Drive unit model |

GS2024 |

GS2030 |

GS2045 |

GS2050 |

GS2075 |

GS2100 |

GS2148 |

GS2200 |

| Rated output current |

7A |

12A |

14A |

22A |

32A |

43A |

43A |

63A |

| Max instantaneous output current |

13A |

17A |

25.5A |

28.3A |

42.4A |

56.6A |

84A |

113A |

| Braking resistor |

Built-in braking resistor (optional external braking resistor) |

External braking resistor |

| Drive unit model |

GS3048 |

GS3050 |

GS3075 |

GS3100 |

GS3148 |

GS3150 |

GS3198 |

GS3300 |

| Rated output current |

13A |

14.1A |

26A |

42.4A |

42.4A |

48A |

58A |

102A |

| Max instantaneous output current |

28.3A |

28.3A |

42.4A |

56.6A |

84.9A |

84.9A |

113A |

168A |

| Braking resistor |

External braking resistor |

| Drive unit model |

GS4048 |

GS4050 |

GS4075 |

GS4100 |

GS4148 |

GS4150 |

GS4198 |

| Rated output current |

13A |

14.1A |

26A |

42.4A |

42.4A |

48A |

63.6A |

| Max instantaneous output current |

28.3A |

28.3A |

42.4A |

56.6A |

84.9A |

84.9A |

113.1A |

| Braking resistor |

External braking resistor |

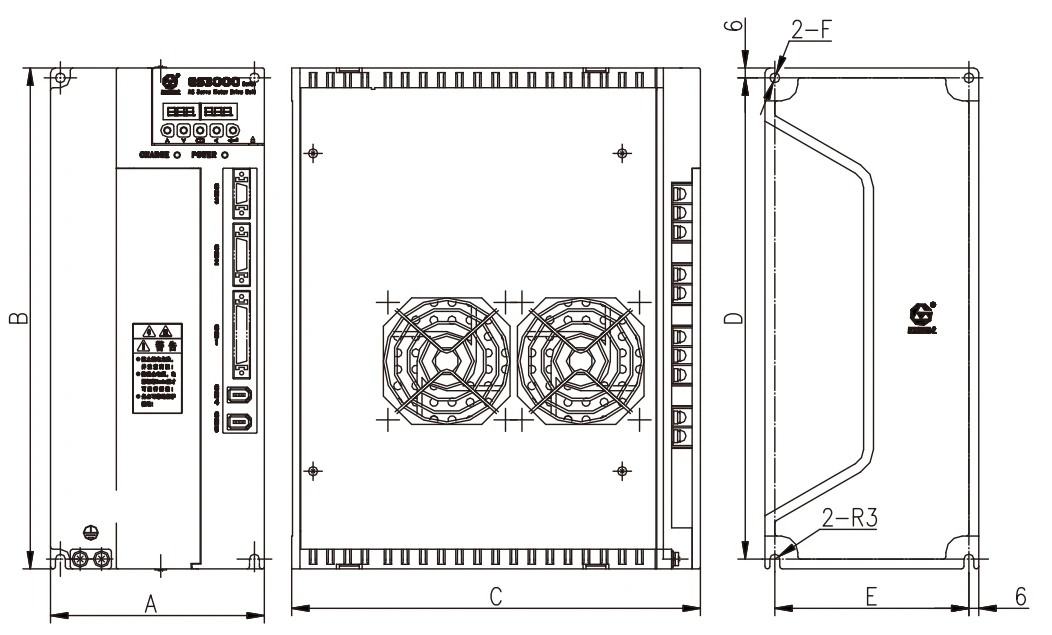

| Product Model |

A |

B |

C |

D |

F |

E |

| GS2024 |

55 |

175 |

179 |

165±0.25 |

43±0.25 |

φ6 |

| GS2030/GS2045 |

91.6 |

190 |

182 |

178±0.25 |

78±0.2 |

φ6 |

| GS2050/GS3048 |

112 |

230 |

182 |

218±0.25 |

100±0.2 |

φ6 |

| GS2075/GS3050 |

120 |

270 |

218 |

258±0.25 |

108±0.2 |

φ6 |

| GS2100/GS3075/GS2148 |

130 |

305 |

248.5 |

293±0.25 |

118±0.2 |

φ6 |

| GS3100/GS3148/GS2200 |

160 |

305 |

273.5 |

293±0.25 |

148±0.2 |

φ6 |

| GS3150/GS3198 |

172 |

350 |

288 |

334±0.25 |

155±0.2 |

φ7 |

| List of GS series servo drives adapted to SJT series servo motors |

| |

Motor Specifications |

Encoder |

Adapter drive model |

| |

Motor model |

Rated power kW |

Rated torque N·m |

Rated speed

rpm |

Rated current A |

A2 |

| 1 |

80SJTA-M024C |

0.5 |

2.4 |

2000 |

2.5 |

√ |

GS2024T |

| 2 |

80SJTA-M024E |

0.75 |

2.4 |

3000 |

3.8 |

√ |

| 3 |

80SJTA-M032C |

0.66 |

3.2 |

2000 |

3.2 |

√ |

| 4 |

130SJT-M040D |

1.0 |

4 |

2500 |

4 |

√ |

| 5 |

80SJTA-M032E |

1.0 |

3.2 |

3000 |

5.5 |

√ |

GS2030T |

| 6 |

110SJT-M040D |

1.0 |

4 |

2500 |

4.5 |

√ |

| 7 |

110SJT-M040E |

1.2 |

4 |

3000 |

5 |

√ |

| 8 |

130SJT-M050D |

1.3 |

5 |

2500 |

5 |

√ |

| 9 |

130SJT-M060D |

1.5 |

6 |

2500 |

6 |

√ |

| 10 |

130SJT-M100B |

1.5 |

10 |

1500 |

6 |

√ |

| 11 |

110SJT-M060D |

1.5 |

6 |

2500 |

7 |

√ |

GS2045T |

| 12 |

110SJT-M060E |

1.8 |

6 |

3000 |

8 |

√ |

| 13 |

130SJT-M050E |

1.57 |

5 |

3000 |

7.2 |

√ |

| 14 |

130SJT-M060E |

1.88 |

6 |

3000 |

7.8 |

√ |

| 15 |

130SJT-M075D |

1.88 |

7.5 |

2500 |

7.5 |

√ |

| 16 |

130SJT-M075E |

2.36 |

7.5 |

3000 |

9.9 |

√ |

GS2050T |

| 17 |

130SJT-M100D |

2.5 |

10 |

2500 |

10 |

√ |

| 18 |

130SJTB-M150B |

2.4 |

15 |

1500 |

10 |

√ |

| 19 |

175SJT-M150B |

2.4 |

15 |

1500 |

11 |

√ |

| 20 |

175SJT-M120E |

3 |

9.6 |

3000 |

13 |

√ |

GS2075T |

| 21 |

175SJT-M150D |

3.1 |

12 |

2500 |

14 |

√ |

| 22 |

175SJT-M180B |

2.8 |

18 |

1500 |

15 |

√ |

| 23 |

130SJTE-M150D |

3.9 |

15 |

2500 |

19.5 |

√ |

GS2100T |

| 24 |

175SJT-M180D |

3.8 |

14.5 |

2500 |

16.5 |

√ |

| 25 |

175SJT-M220B |

3.5 |

22 |

1500 |

17.5 |

√ |

| 26 |

175SJT-M220D |

4.5 |

17.6 |

2500 |

19 |

√ |

| 27 |

175SJT-M300B |

4.7 |

30 |

1500 |

24 |

√ |

| 28 |

175SJT-M300D |

6 |

24 |

2500 |

27.5 |

√ |

GS2148T |

| 29 |

175SJT-M380B |

6 |

38 |

1500 |

29 |

√ |

| 30 |

130SJTG-M040GH |

1.7 |

4 |

4000 |

4.8 |

√ |

GS3048T |

| 31 |

130SJTG-M050GH |

2.1 |

5 |

4000 |

6 |

√ |

| 32 |

130SJTG-M060GH |

2.5 |

6 |

4000 |

7.2 |

√ |

| 33 |

130SJTG-M075GH |

3.1 |

7.5 |

4000 |

7.5 |

√ |

| 34 |

130SJTG-M100GH |

4.2 |

10 |

4000 |

10 |

√ |

GS3050T |

| 35 |

175SJTG-M120EH |

3.8 |

12 |

3000 |

10.5 |

√ |

| 36 |

175SJTG-M150EH |

4.7 |

15 |

3000 |

12.5 |

√ |

GS3075T |

| 37 |

175SJTG-M180EH |

5.7 |

18 |

3000 |

15.5 |

√ |

| 38 |

175SJT-M380BH |

6 |

38 |

1500 |

15 |

√ |

| 39 |

175SJTG-M220EH |

6.9 |

22 |

3000 |

18.5 |

√ |

GS3100T |

| 40 |

175SJT-M500BH |

7.8 |

50 |

1500 |

20 |

√ |

| 41 |

175SJTG-M300EH |

9.4 |

30 |

3000 |

25 |

√ |

GS3148T |

| 42 |

175SJTG-M380EH |

11.9 |

38 |

3000 |

32 |

√ |

| 43 |

175SJT-M380DH |

7.9 |

38 |

2500 |

26 |

√ |

| 44 |

175SJT-M500DH |

10.5 |

40 |

2500 |

33 |

√ |

| Note: The GS-N series feed servo drive unit is equipped with a 5000-line incremental encoder servo motor as standard; if you need a servo motor with a power-off brake and other outlet methods, please refer to the GSK servo motor ordering guide |

GS4000

GS4048Y-NP2

GS4050Y-NP2

GS4075Y-NP2

GS4100Y-NP2

GS4148Y-NP2

GS4150Y-NP2

GS4198Y-NP2

GS4048Y-CP2

GS4050Y-CP2

GS4075Y-CP2

GS4100Y-CP2

GS4148Y-CP2

GS4150Y-CP2

GS4198Y-CP2

GS4048Y-LP2

GS4050Y-LP2

GS4075Y-LP2

GS4100Y-LP2

GS4148Y-LP2

GS4150Y-LP2

GS4198Y-LP2

|