Guarantee machine accuracy and improve work efficiency.

Channel 1 is turned and channel 2 is milled;

The ladder diagram realizes the lathe passage with Shenyang SFW-12 station servo turret, and the milling machine channel is equipped with HWD-24 station disc knives;

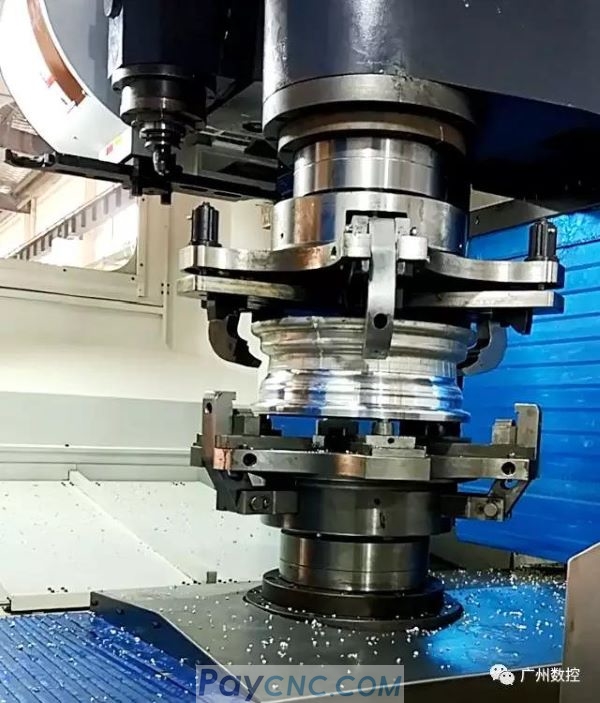

It can realize shaft/radial turning, drilling, boring, milling, tapping and other composite processing;

The ladder diagram channel 1 increases the control logic of the Shenyang SFW-12 station servo turret, and the channel 2 increases the control logic of the HWD-24 station disc magazine.

The two-channel X, Z, Y and B axes are all servo motors with 17-bit absolute encoders. The two-channel spindles are equipped with HEIDENHAIN ERA180 encoders and subdivision boxes IBV600 1000 lines as feedback devices.

The matching system channel 1 parameter is the lathe code command, the channel 2 parameter is the milling machine code command, and the dual channel realizes one vehicle and one milling configuration.

The workpiece transfer processing is realized between the two channels, and the processing efficiency is improved;

The ladder diagram realizes the normal SGW-12 station servo turret and the HWD-24 station disc knives to change the knife normally;

The machine tool realizes drilling, milling and tapping of end faces and cylindrical faces.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|