GSK25iMc is an iteratively upgraded high-performance, high-reliability five-axis CNC system based on the original GSK25i series. It is suitable for the control of multi-function machining centers, boring, milling, drilling, turning, grinding and other machine tools, compound machine tools and automation equipment.

GSK25iMc VS GSK25iMc

The improvement of GSK25iMc relative to GSK25iMb

01

Brand new high-performance hardware platform, processing speed is greatly improved;

Integrated low power consumption, maintenance-free metal structure chassis, increase service life.

02

The independent key operation panel adds two sets of differential signal input interfaces (can be used for the second and third handwheels);

The independent key operation panel adds user IO input and output control functions, 16 input points and 4 output points.

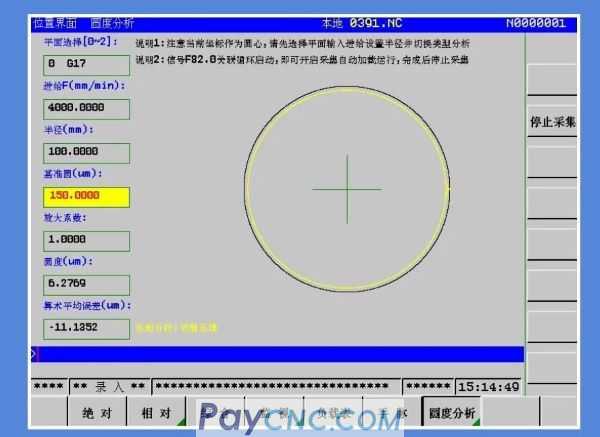

03Added roundness error analysis

One-click collection of actual roundness on site and preset standard circles for comparison and error analysis, realize data visualization, assist roundness test, and simplify debugging steps;

It supports 4 data sources including PID, servo feedback, grating feedback and commands.

04 Added coordinate centering

Move the feed and read the two-point coordinates of the workpiece contour, and quickly complete the two-point centering;

Support the preset height of the tool block;

Protect the surface of the workpiece to the greatest extent while simplifying user calculations;

Support 6 standard workpiece systems;

Protect the surface of the workpiece to the greatest extent while simplifying user calculations;

Supports two kinds of conventional workpiece contour coordinates of rectangle and circle.

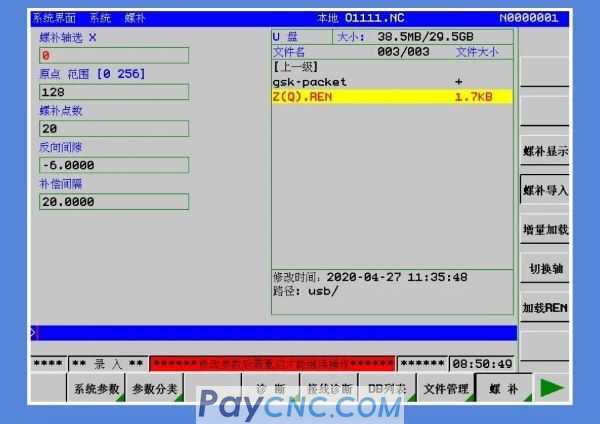

05Added automatic setting function of screw compensation

One-click loading of the corresponding axis and selecting the REN file can quickly complete the pitch compensation parameter setting and pitch compensation data writing;

Realize the zero operation of screw compensation parameters and data, completely avoid data errors or omissions caused by manual setting, and strictly control the correct rate of data.

06With higher performance servo motor, higher precision encoder

Flat structure, suitable for special installation occasions;

Easy-to-plug design, higher protection level;

Improve machining accuracy and surface quality

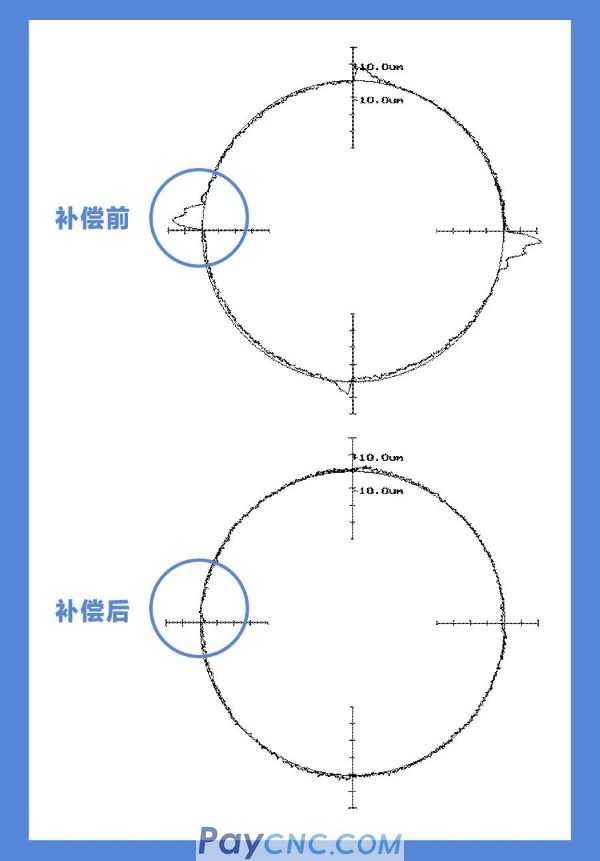

07Processing roundness improved significantly

Application of high-precision interpolation algorithm, high-response servo, friction compensation function to obtain high processing performance.

Typical application effect

Improve roundness

Eliminate the traces of the elephant

08 Further optimization of interpolation path, speed and acceleration

Curve interpolation path smoothing algorithm optimization

Speed and acceleration smoothing algorithm optimization

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|