GSK986GS new platform CNC system is a new generation of wear-through CNC system launched by Guangzhou CNC. It adopts dual CPU architecture and supports multi-task operation, multi-channel, secondary development, flexible production configuration (network, interconnection) and other functions.

The standard configuration is 4 axes and 3 linkages, which can be expanded up to 6 channels and 10 feed axes;

Motor equipped with absolute encoder;

The highest speed is 60000mm / min, the highest speed and high precision;

Super strong program instruction processing ability, preprocessing speed can reach 1000 / s;

The interpolation cycle is 1ms and the control accuracy is 0.1um / 0.0001 °.

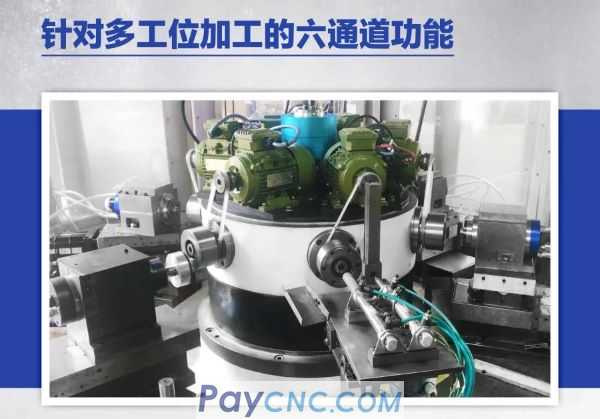

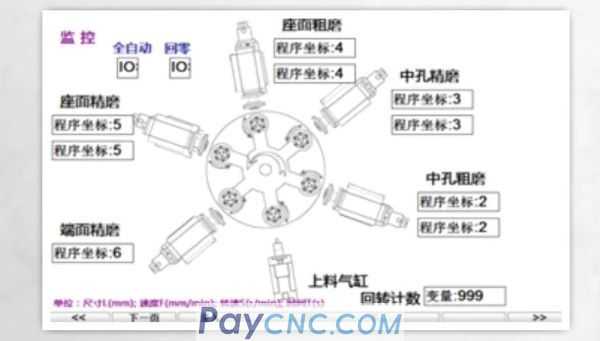

In order to meet the needs of efficient production, the new platform CNC system of GSK986GS has developed six-channel functions to meet the needs of customers. It can simultaneously meet the six-station seat / face grinding and middle hole grinding. Compensation, program conversion for grinding process, workpiece quality management, machine tool status monitoring, fault self-diagnosis and abnormal alarm and other comprehensive processing control functions, the operation input interface is simple and convenient. The six-channel function control interface has many user-defined functions, which can be defined according to the needs of customers to improve the user experience.

Multi-axis multi-channel control 01

Spindle synchronous control, realizing dynamic exchange of targets, etc .; feed axis synchronous control, coordinating strongly coupled multi-input / output control objects; multiple channels executing in parallel, realizing one system to control multiple machine tools or multi-station machining; each The channel controls each axis to realize asynchronous control of special machine tools.

Six channel interface customization 02

The six-channel work operation interface can be customized, and the definition of each station can be edited according to user needs, making the operation simple and easy to understand.

|