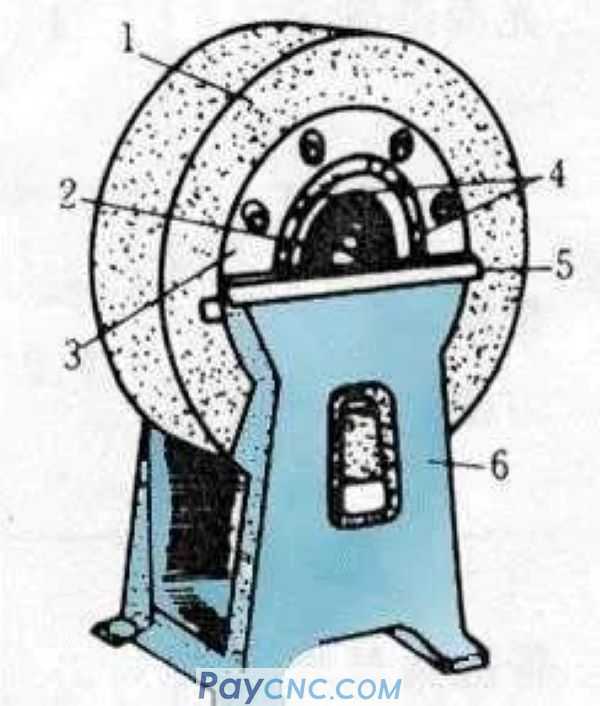

The grinding wheel balance frame is an accessory that the grinder must be equipped with. It can be used to statically balance the grinding wheel to achieve the purpose of using the grinding wheel correctly. It is one of the means to check the uniformity and geometric shape of the helper wheel. It is the key to ensuring the user's grinding quality . The level meter can also detect the static balance of precision workpieces. Two: production process

The grinding wheel balance frame uses high-quality materials as the balance shaft. After heat treatment and precise processing and assembly, it has high precision and stable performance. It is an ideal machine tool accessory.

Three: Specifications

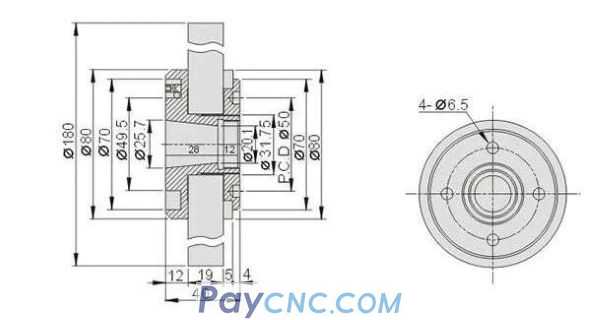

The specifications and special specifications of the grinding wheel balance frame can be customized. Generally, the grinding wheel with a diameter greater than >125mm must be balanced so that the center of gravity of the grinding wheel coincides with the axis of rotation. The unbalanced grinding wheel will vibrate when rotating at high speed, which will affect the processing quality and accuracy of the machine tool. In severe cases, it will also cause machine damage and grinding wheel fragmentation. The original problem of imbalance is mainly the uneven density of each part of the grinding wheel, asymmetric geometry and Installation eccentricity, etc. Therefore, balance must be performed before installing the grinding wheel. The balance of the grinding wheel has two types: static balance and dynamic balance. Under normal circumstances, only static balance is required, but when high-speed grinding speed is greater than >50m/s and high-speed grinding, dynamic balance must be performed. When balancing, install the grinding wheel on the balance mandrel, and then place the grinding wheel with the mandrel flat on the balance guide rail of the grinding wheel balance bracket. The grinding wheel will swing back and forth until the swing stops. The balanced grinding wheel can stand still in any position. If the grinding wheel is unbalanced, the heavier part will always turn to the position of the movable balance block at this time to achieve balance.

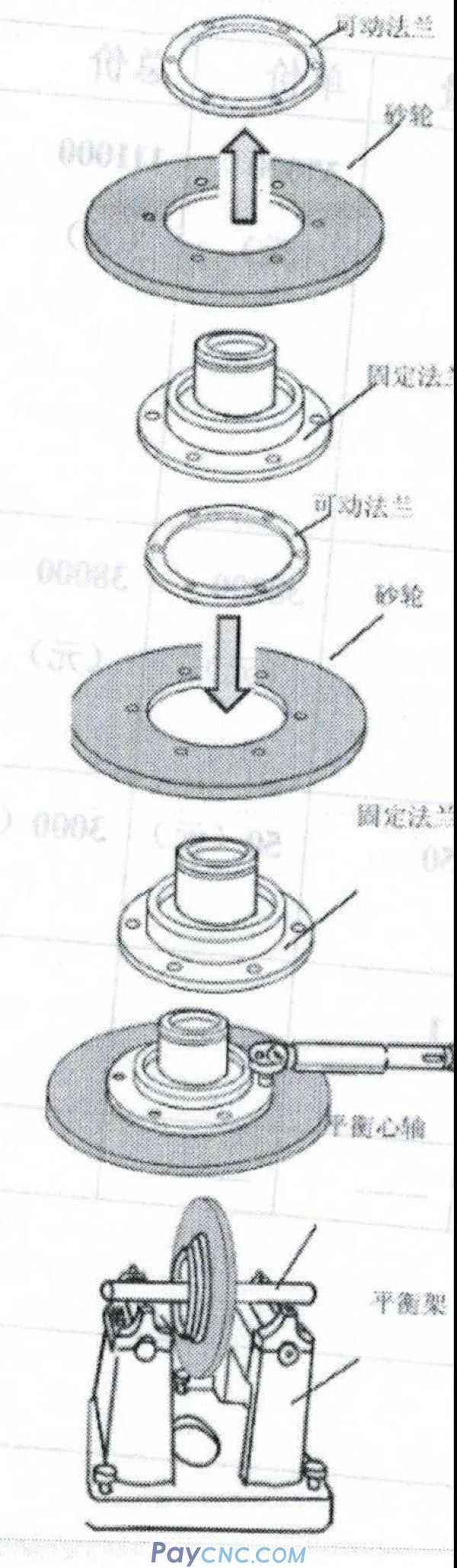

How to use the wheel balance bracket and steps. Loosen and remove the screws on the flange. Take out the movable flange upward and remove the grinding wheel from the fixed flange. Clean the fixed flange surface, use oil stone to remove the scratches and repair corrosion on the contact surface of the flange and the grinding wheel. Loosen the screws of the balance weight in a clockwise direction, and remove the three balance grinding wheel blocks from the groove of the flange. Clean the contact surface of the flange and the new grinding wheel with oilstone to remove the damage and rust. Clean the inside of the grinding wheel and install the grinding wheel on the fixed flange.

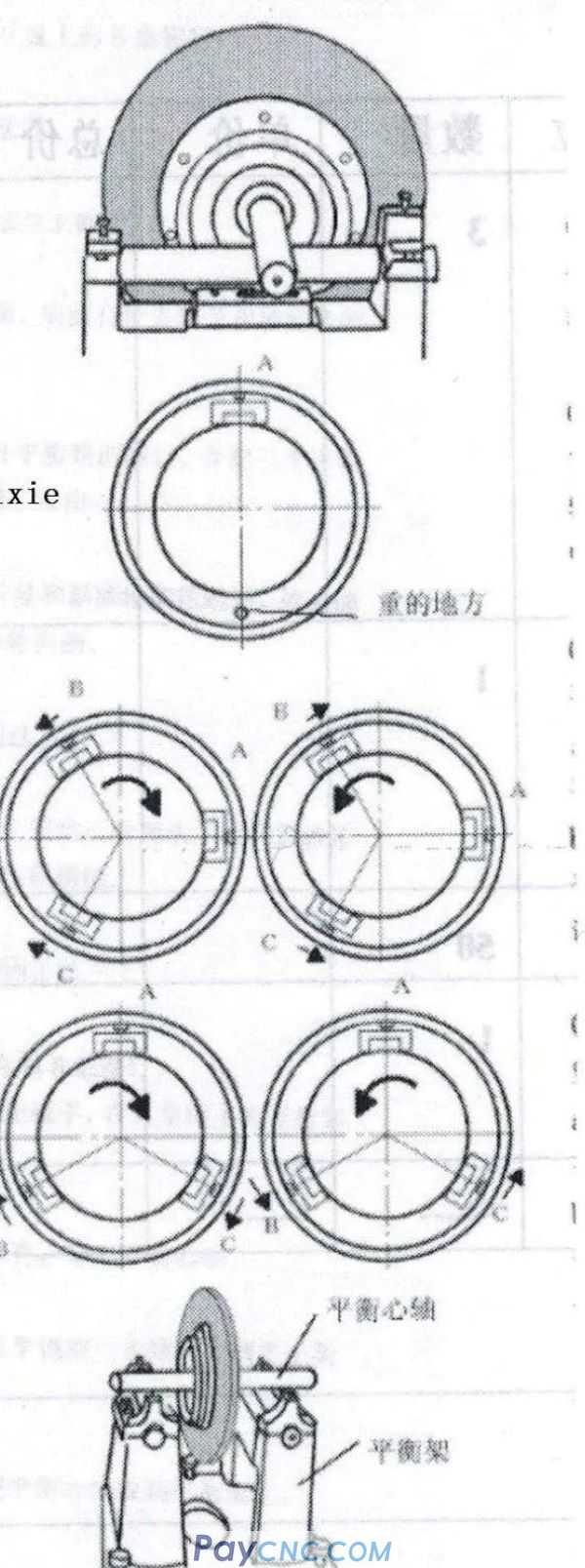

Clean the movable flange. Use oilstone to clean the contact surface of the flange and the new grinding wheel, remove the scratches and rust, and install the movable flange to the fixed torque of the fixed flange screw. Tighten the screws on the diagonal. Clean the taper hole of the flange and put on the balance mandrel. Look at the leveling adjustment of the three screws of the balance frame, level the balance and place the balance spindle on the balance frame. When the grinding wheel has an imbalance, the heavy ground is below when it stops. At this time, use chalk to make a mark on the upper side of the flange. Install a balance weight on the chalk mark. Rotate the screw counterwise to gently tighten the balance weight in the groove of the flange. Rotate the grinding wheel, and install a balance block on the left and right distances from the chalk mark. Turn the screw counterclockwise to gently tighten the balance weight in the groove of the flange. Rotate the grinding wheel so that the marked chalk mark is in a horizontal position and release your hand. When turning clockwise, follow the method shown on the left: move the balance weight by the same angle in the relative direction. When turning counterclockwise, follow the method shown on the left: move the balance weight in the opposite direction by the same angle. Adjust until the hand leaves, the grinding wheel is still. Rotate the grinding wheel so that the marked chalk mark is in a vertical position, and release your hand. When turning clockwise as shown in the figure, follow the method shown on the left: move the balance weight clockwise in the same direction by the same angle. When turning counterclockwise, follow the method shown on the left: move the balance weight counterclockwise in the same direction by the same angle. Adjust until the hand leaves, the grinding wheel is still. Repeat the operation of the item to balance the grinding wheel. After balancing, tighten the screws of the balance weight. Remove the grinding wheel from the balance frame and remove the balance mandrel from the flange. The balance correction of the grinding wheel is completed.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|