Features:

·Using 35°~40° large helix angle that emphasizes cutting sharpness.

·The chip flute design takes into account the infiltration of cutting oil and chip removal.

·The cutter body is made of high-vanadium high-speed steel with high toughness.

Processing case:

Difficult to process Kovar alloy can also be drilled easily, realizing efficient and durable drilling.

After machining 230 holes (approximately 2.5m), the tool wear is small and the machining can still be continued.

02 VPH-GDS (Powder high-speed steel short edge drill for quenched and tempered steel)

Features:

·Large core thickness design realizes high rigidity of the tool.

·The cutter body is made of powdered high-speed steel, and the surface coating can be selected according to the processing material.

Processing case:

A well-known domestic electronic cigarette manufacturer uses VPH-GDS to process N6 pure nickel electronic cigarette electrodes.

The competitor's product is the mainstream high-speed steel drill bit in the market. In the test, the processing life of OSG's VPH-GDS is twice that of the competitor's product.

Scope of application:

03 AD/ADO-DIN hard alloy DIN standard drill bit

Features:

The series is the most representative cemented carbide 2-blade drill series in the A-Brand series. On the basis of AD/ADO, OSJ has developed the DIN specification series, which adopts the DIN6537 standard in the design of overall length, groove length and shank diameter.

·The surface adopts the EgiAs coating independently developed by OSG, which has high wear resistance and can optimize the toughness of the tool.

·The large chip pocket can improve the chip removal performance of the tool.

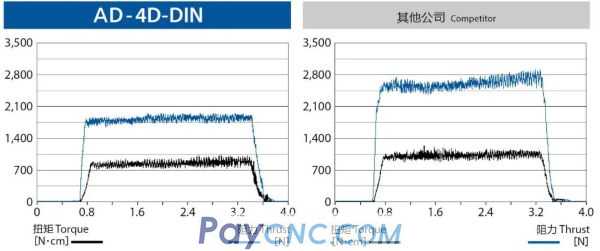

·The wavy blade can cut finely divided chips, and maintain low resistance and stable torque during processing.

Processing case:

AD-4D-DIN can maintain low resistance and stable torque during processing.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|