The 218MC data backup, restore and transfer function adopts a relatively simple way, because the CNC machine tool is composed of the machine tool hardware and the CNC system software, and the CNC machine tool parameter is a key value in the system software, which determines The functions and control accuracy of CNC machine tools are important data that the machine tool manufacturer obtains after a series of tests and adjustments according to the characteristics of the machine tool. It is the key to ensuring the normal operation of the CNC machine tool. Once a parameter is lost or incorrectly changed, the machine tool Some of the functions cannot be realized or the system is chaotic or even paralyzed. Therefore, it is very necessary to perform correct, complete and effective parameter backup after the CNC machine tool has been debugged or adjusted. The backup, restoration and transmission functions of system data are thus born. The following details the backup, restoration and transmission functions of system data:

01

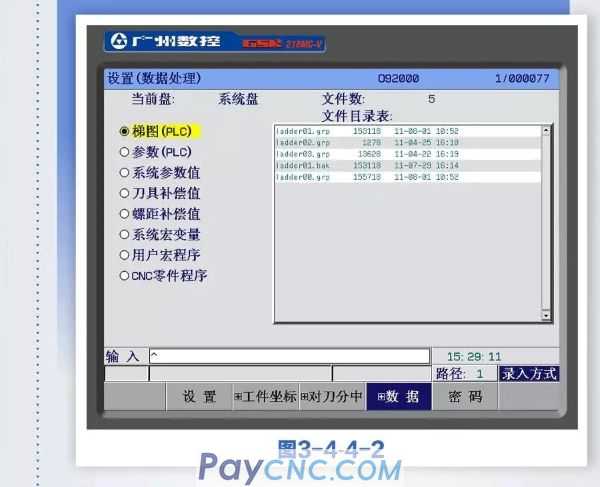

Press【+Data】soft key to enter the setting (data processing) interface. User data (ladder diagram, ladder diagram parameter, system parameter value, tool compensation value, pitch compensation value, system macro variable, user macro program, CNC part program) can be backed up (save) and restored (read); U disk or PC for data output and input operations. While backing up and restoring data, it does not affect the part program stored in the CNC (see Figure 3-4-1)

Operation method:

Press the soft key【Password】to set the corresponding level password in the password interface. (The default password of the machine tool manufacturer is 111111 or ADMIN)

Press [Data] twice to enter the data processing operation interface, as shown in Figure 3-4-4-2

button

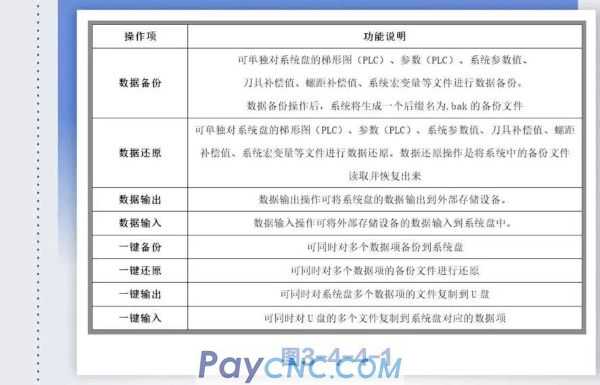

Enter the function of each operation item on the next page, see Table 3-4-4-1

Press the up and down arrow keys to select the target file, and press the left and right keys to switch between the data item directory and the file directory.

Press the corresponding soft keys to perform data backup, data restore, data output, data input, one-key backup, one-key restore, one-key output, and one-key input operations.

Note:

When the I/O channel is set to U disk, the data output and data input soft keys have the same function.

For data output/input operations, please ensure that the I/O channel settings are correct. When using a U disk, the I/O channel should be set to 2; when using the transmission software through a PC, the I/O channel should be set to 0 or 1.

The content of one-key operation is determined by the password authority. (The default password of the machine tool manufacturer is 111111 or ADMIN)

1. It is set by bit parameter NO:54#7; at the time of debugging and above authority, whether one-key input/output is valid for the part program.

2. Set by bit parameter NO: 27#7: whether to prohibit editing of program number 80000-89999 subprogram.

3. Set by bit parameter NO:27#4: whether to prohibit editing of the program number 90000-99999 subprogram.

The LADCHI**.TXT file is invalid after being transferred to the system, and it needs to be powered off to be valid.

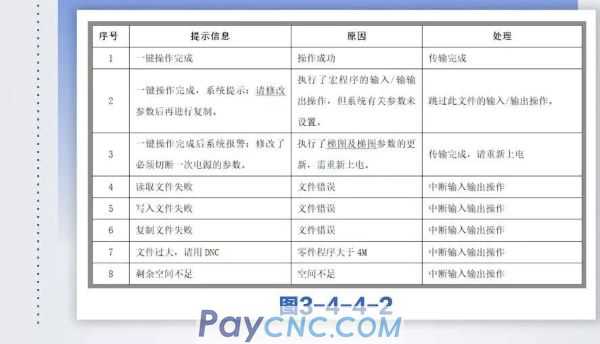

In the process of data processing, the system has set up relevant operation prompts, and the prompt content is shown in Table 3-4-4-2

02 end

Through the above description, you can quickly understand the data backup, restoration and transmission functions, and effectively provide an intuitive and concise display interface. According to the fault phenomenon and parameter description, find the corresponding parameters for troubleshooting and set the correct parameters. This method is very practical in the process of using machine tool parameters for equipment maintenance. This method can be used to deal with many common machine tool failures. When the parameters are lost and changed in a wide range, the only way to restore the parameters is to use the backup and reinstallation of the parameters. Use the backup data of the machine tool to download and restore parameters. This method is simple, easy to implement, efficient and reliable, and is the main method for parameter recovery.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|