The machining center is equipped with a disc-type tool magazine. Occasionally, there will be a tool jam during tool change. In order to enable the majority of users to quickly solve the problem, the following uses VMC850 / GSK25iM-H as a case for fault analysis and troubleshooting.

01 Failure phenomenon

During the tool change process, the tool magazine robot is out of position due to an alarm, as shown in Figure 1

02 Fault diagnosis

Most of the faults are caused by insufficient air pressure alarm. Of course, there are some small probability events such as power failure during the tool change.

03 Troubleshooting

If the card cutter fails, you must first solve the problem of insufficient air pressure or restore the normal power supply of the machine tool, and then manually reset the manipulator. The specific operation methods are as follows.

The 40 # tool magazine uses a 12mm wrench. There is a motor with a semi-circular pull ring (brake pull ring) above the tool magazine.

Pull the pull ring upwards to the top of the knife to release the manipulator brake.

Note: Some manipulator motors use pull-dry brakes, and the operation method for releasing the brakes is shown in Figure 4.

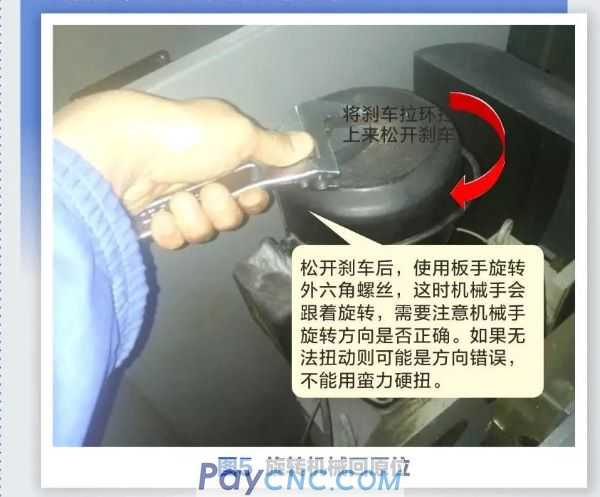

Then use a wrench to turn the six-angle screw of the motor shaft, as shown in the specific direction shown in Figure 5, until the manipulator is shaken back to its original position.

Whether the mechanical knife is reset can see the sensor light in the window of the tool magazine, as shown in Figure 6, and then put the brake ring of the motor down to complete the mechanical reset.

Finally, the vertical knife sleeve can be leveled, find the two-way solenoid valve as shown in Figure 7, and manually return the knife sleeve to the horizontal.

There are two small buttons under the solenoid valve. The valve is red. The colors of other valves may be different, but the position is the same. The function is the same. As shown in Figure 8, press the button. Press another), the tool sleeve is level, and the tool magazine is returned.

04 Conclusion

The types of tool magazines commonly used in machining centers are disc-type tool magazines, bucket-type tool magazines, and chain-type tool magazines. Among them, the largest sales are disk-type tool magazines, because of their fast tool change speed and high stability. Well protected and loved by customers. The tool magazine of the machining center is a very frequent start and stop component of the CNC machine tool during use. Therefore, it is very important to regularly check the fastening of each part of the tool magazine, and it is also an important measure to avoid the failure of the tool magazine.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|