In order to ensure the safe operation of CNC machine tools, the straight line of the machine tool is usually set with two protection "defense lines" (soft limit (parameter setting limit) and hard limit (travel switch limit). In the actual use of the 218MC system bus version, since the absolute encoder is used, the limit switch can not be installed, because the hardware limit can be set in [Bus Setting], this alarm is directly produced within the system, if the customer wants to install Hardware limit switches are also available, but these two methods can only choose one of them, and cannot be used at the same time. The pulse version is generally recommended to install a hardware limit switch, so as to ensure safety. The following describes in detail the adjustment method of each axis limit of GSK218MC system:

01 authority login

When setting or modifying software parameters, you first need to obtain the corresponding permissions, as follows:

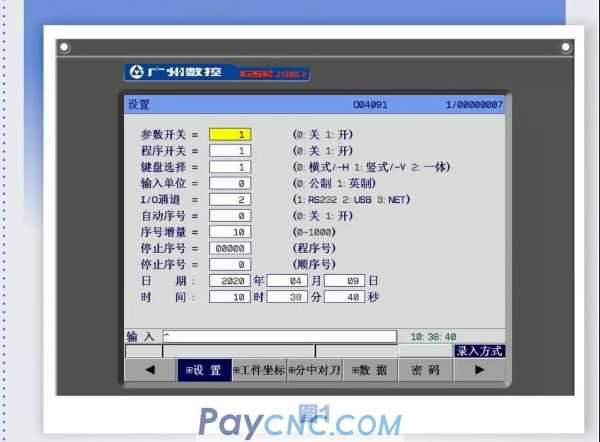

Press the setting key to enter the setting interface, the cursor moves to the parameter switch, in the input mode, enter 1 to open the parameter switch;

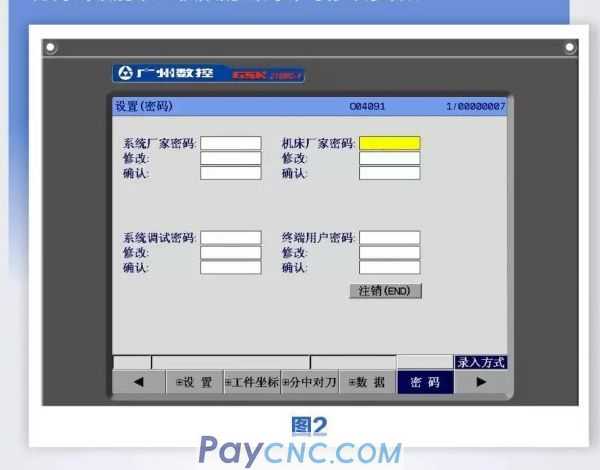

Press the [Password] soft key again to enter the [Setting (Password)] page, enter the password of the system debugging level or higher to modify the parameters.

02 Debugging process of hard limit of each axis

Press the system key to enter the system interface, and use the corresponding soft key to switch to display [+ bus configuration] interface

In the input mode, the cursor moves to the setting, press the enter key twice, after setting the machine zero, move the yellow square to the positive and negative side sister of the corresponding axis, manually set the negative boundary and The positive boundary makes the current machine tool absolute coordinates shift forward or backward by one value, and finally set the bit parameter No.61 # 6 to 1, the positive and negative limit is valid. Remove the alarm: As shown in Figure 4, a hardware limit overtravel alarm appears, and the tool can only move in the opposite direction. The tool moves in the opposite direction until it exits the prohibited area, and the overtravel alarm is automatically canceled.

External hard limit debugging process of each axis

Move the coordinate axes slowly in manual or handwheel mode to verify the effectiveness of each axis's overtravel limit switch, the correctness of the alarm display, and the effectiveness of the overtravel release button; when an overtravel triggers a hardware limit switch, An alarm will appear in the system. Press the overtravel release button and move in the opposite direction to cancel the system alarm. GSK218MC series system provides two connection methods of stroke limit switch to meet user needs.

For safety reasons, the hard limit switch uses a normally closed contact switch. It is not allowed to install a normally open electric shock switch. That is, when the external switch is turned off, it is considered that the knife reaches the limit point, and an alarm will occur, that is, the corresponding [diagnostic 】 【X signal】 If the corresponding point is 0, it will alarm.

Commissioning of two stroke limit switches

Use two travel switches, that is, one travel switch for each axis's positive and negative direction limit, K6.0 needs to be set to 0, the default value is 0.

Commissioning of single stroke limit switch

Use a single travel switch, that is, use only one travel switch, and use two stops to limit the positive and negative limit, you need to set K6.0 to 1, the default value is 0.

Note: When the machine tool is not equipped with a travel switch, please short-circuit the limit switch signal of the corresponding axis to the system + 24V, or set bit parameter N0; 61 # 6 (whether or not to ignore the hardware limit alarm) to 1.

03Soft limit adjustment

Remove the alarm: As shown in Figure 6, a software limit overtravel alarm appears, and the tool can only move in the opposite direction. The tool moves in the opposite direction until it exits the prohibited area, and the overtravel alarm is automatically canceled.

Stored stroke check 1: The outside of this area is a no-entry area. Machine tool manufacturers often set this area as the maximum stroke of the machine tool. Software limit setting parameters P66-P73: (this parameter is the machine coordinate value), as shown in Figure 7:

Bit parameter 10 # 1: Whether stroke detection before moving. As shown in Figure 8, when the program is executed, the system will first pre-read and calculate the coordinates that will be run. Using this function, the position of the overtravel in the subsequent program will be detected during the pre-read, and the system will alarm in advance without waiting When the program is executed to the alarm line, the alarm will be saved in advance to save time.

Bit parameter 11 # 6: After the power is turned on, before the manual return to the reference point, is the stroke detection performed (0: not performed, 1 performed). As shown in Figure 8, the software limit is established based on the machine tool coordinates. The incremental machine cannot determine the position of the machine before the machine zero is found. The parameters are used to determine whether the software limit alarm is detected before the machine returns to zero.

Bit parameter 11 # 7: Alarm during overtravel (0: before, 1: after). As shown in Figure 8, select the alarm before overtravel. When the machine coordinate value when moving the axis reaches or exceeds the first 5mm of the preset data parameter, a software limit alarm will be generated for early protection. When overtravel is selected, the alarm will occur, and the software limit alarm will only occur when the machine coordinate value is equal to or greater than the set value.

04 Conclusion

The operation of the above steps can quickly solve the problem of system limit. Guangzhou CNC's 208D system and 990MC system also refer to this method for operation adjustment and elimination. However, it should be noted that the soft limit cannot exceed the range of the hard limit, otherwise it will not play a protective role.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|