Maintaining CNC Control Systems

Best Practices for Reliability and Precision

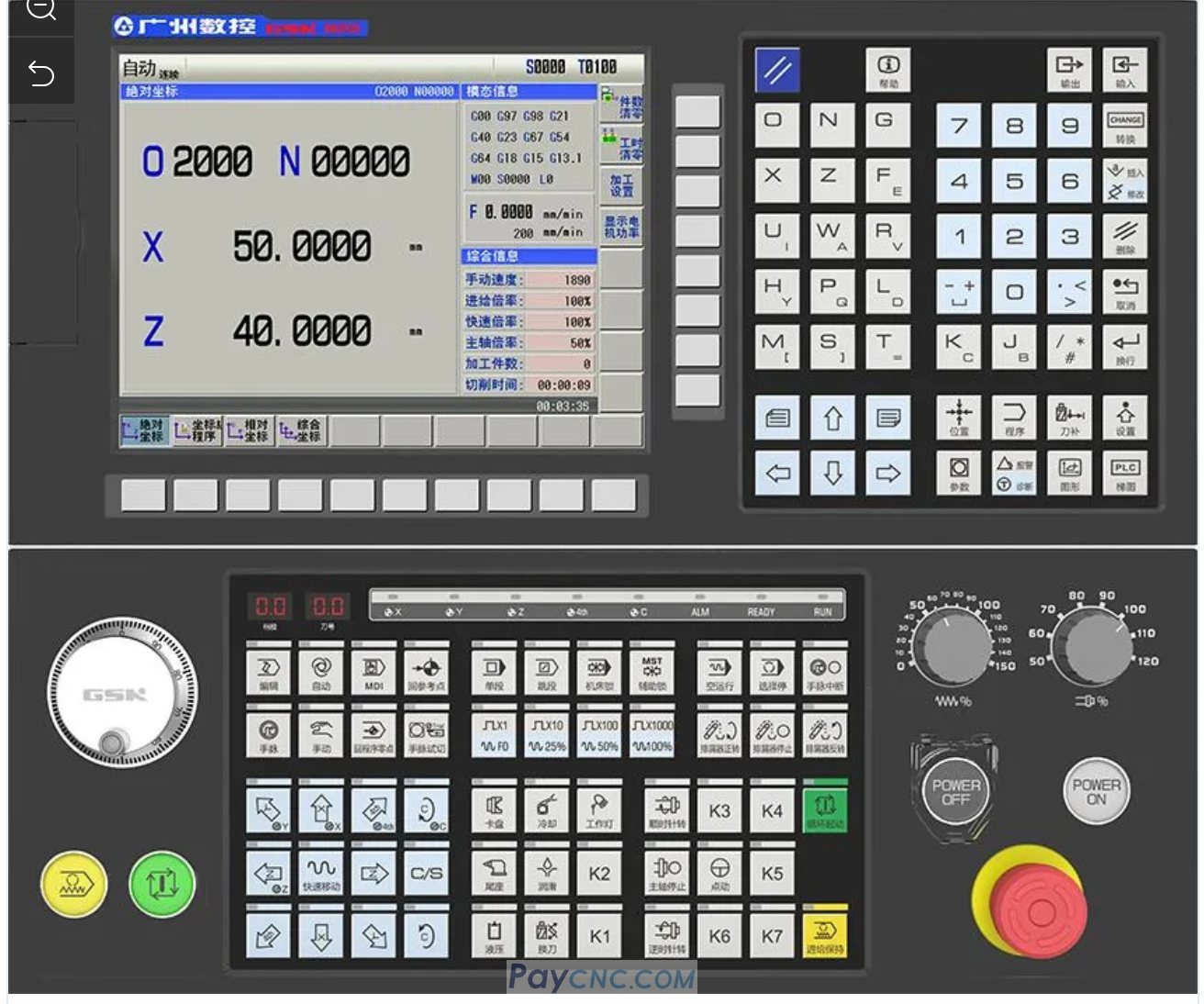

Computer Numerical Control (CNC) systems are at the core of modern manufacturing. They combine mechanical hardware, electronic components, and complex software to deliver high-precision machining across a wide range of industries. Because CNC machines often operate continuously and under demanding conditions, maintaining the CNC control system is essential to ensure long-term accuracy, productivity, and safety.

This article outlines key principles, common failure points, and best practices for maintaining CNC control systems.

Importance of CNC Control System Maintenance

The control system acts as the “brain” of the CNC machine. It interprets G-code, manages motion control, monitors sensors, and interfaces with mechanical subsystems. When the control system fails or becomes unstable, production stops immediately. Regular maintenance helps to:

Reduce unexpected downtime

Improve machining accuracy and repeatability

Protect electronic components from heat, dust, and vibration

Extend the lifespan of drives, motors, and control modules

Improve operator and machine safety

Common Issues in CNC Control Systems

Electrical Failures

Power supply degradation

Loose terminal connections

Damaged cables or connectors

Grounding and EMI interference problems

Symptoms include boot failures, random resets, screen flickering, or axis alarms.

Software and Parameter Problems

Corrupted system files

Incorrect PLC/PMC logic

Parameter loss due to battery failure

Firmware incompatibility

These issues often result in alarm codes, axis errors, or machine initialization failures.

Cooling and Environmental Issues

Dust accumulation inside the control cabinet

Failed fans or filters

Overheating of servo drives or power modules

Environmental factors—especially humidity—can accelerate corrosion.

Mechanical-Electrical Interface Problems

Encoder feedback errors

Sensor misalignment

Limit switch failure

These commonly cause servo errors, positioning inaccuracies, or prohibited machine movements.

Essential Maintenance Practices

Scheduled Cleaning of Control Cabinets

Remove dust with dry compressed air

Clean or replace filter mats

Inspect ventilation fans

Ensure all boards and connectors are dry and free of corrosion

A clean environment significantly reduces overheating and electrical failures.

Regular Inspection of Power and Grounding Systems

Measure output voltage of the power supply

Check grounding resistance

Ensure proper shielding of signal wires

Tighten terminals and bus bars

Stable power is critical for reliable machine control.

Backup and Verification of Parameters

Regularly back up CNC parameters, PLC/PMC programs, offset tables, and machine configurations

Verify backups after software upgrades or battery replacement

Store backups securely (USB, cloud, or internal network)

This prevents system corruption from turning into a long downtime event.

Servo System Maintenance

Check servo motor temperature and noise

Inspect encoder feedback lines

Verify servo gains, following error, and tuning status

Clean motor cooling channels

Proactive servo maintenance prevents axis instability and mechanical wear.

Battery Monitoring

Most CNC controls rely on batteries to retain memory (FANUC, Mitsubishi, Siemens, etc.).

Replace batteries every 1–2 years

Replace with power ON, when recommended by the manufacturer

Document replacement date and type

Battery failure can result in total loss of parameters.

Troubleshooting Guidelines

When the Control System Fails to Boot

Check power supply output and fuses

Inspect the main CPU board and memory modules

Confirm that system batteries are not dead

Review last known alarms or events

When Axis Alarms Occur

Check servo drive LEDs and alarm codes

Inspect encoder cables

Verify limit and home switches

Check servo gain settings

When the HMI or Display Is Unresponsive

Inspect the display power cable

Test the I/O panel connections

Check the operator panel PCB for damage

Reinstall or reload HMI software if necessary

Upgrading and Modernization

Older CNC systems may lack modern features or spare parts availability. Retrofitting or upgrading the control system can:

Improve motion accuracy

Reduce maintenance costs

Increase processing speed

Enhance connectivity (Ethernet, USB, fieldbus)

Extend overall machine life

Common upgrades include new servo drives, modern CNC controllers, touch-screen HMIs, and updated PLC logic.

Effective maintenance of CNC control systems is essential for maximizing machine uptime, ensuring machining precision, and protecting valuable equipment investments. By following a structured maintenance plan—covering electrical systems, software, cooling, servo components, and backups—manufacturers can significantly reduce failures and extend the lifespan of their CNC machines. |