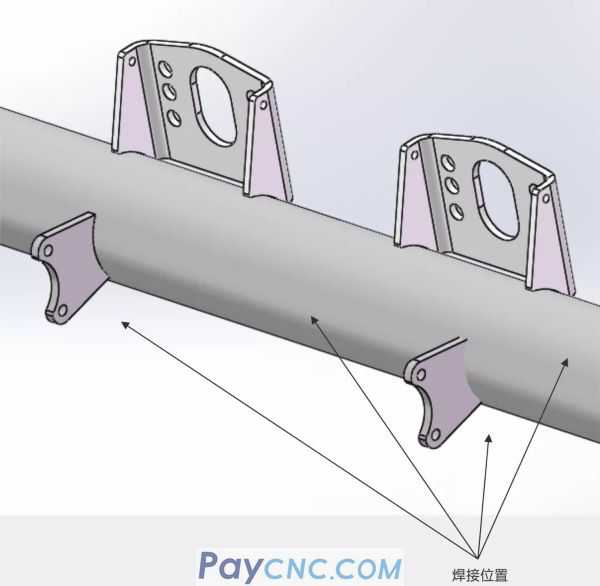

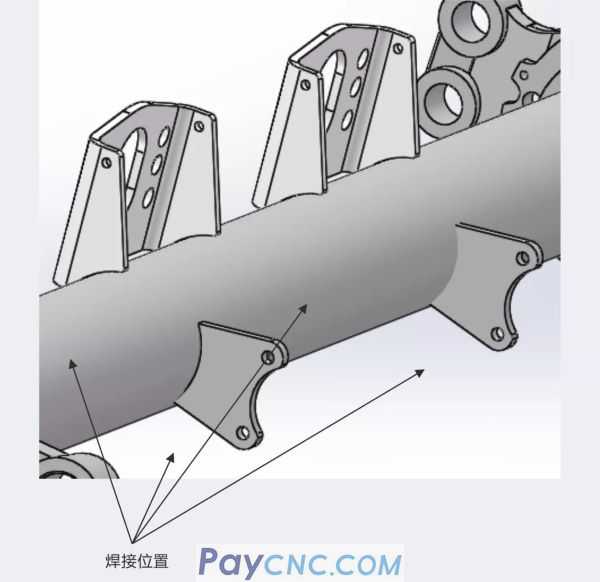

The workpiece has square shaft and round shaft full welding processing;

This welding robot only completes the full welding of the gas chamber seat and support plate;

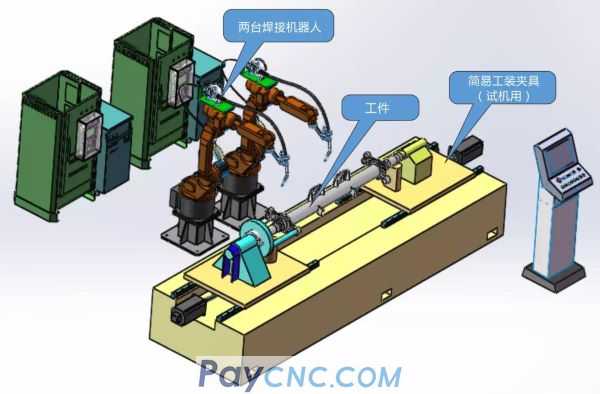

This welding adopts double robot symmetrical welding to reduce deformation, and a set of positioner (tooling);

Robot welding requires starting point location and seam tracking functions.

02

solution

2 RH06 welding robots, 2 gun cleaning mechanisms, 2 sets of anti-collision welding guns;

After the spot welding of the workpiece is completed, manually hoist the axle and weld one side of the complete weld seam;

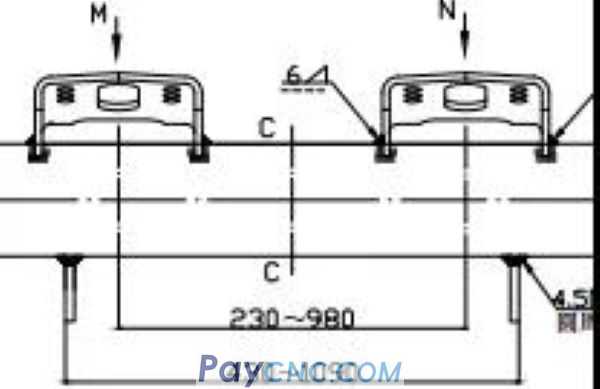

The length of the workpiece changes, which is driven and adjusted by the lead screw and servo motor;

On the other side of the spin welding, the installation and positioning of the axle is supported by an auxiliary cylinder.

03

Application effect

Double-station welding ensures product quality, avoids abnormal deformation problems, and improves work efficiency;

Reducing the burden of manual welding by welders and maintaining uniform stability can reduce the production cost of enterprises.

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|