Principle of reference point return

The turret reference point “machine reference point” is located within the travel range of the turret. the NC unit creates the machine coordinate system, and the machine reference point serves as the origin of this coordinate system. The turret position is controlled by the machine coordinate system reference point. When the machine is first powered up, there is no reference point data in NC. In order to establish the reference point, a return to reference point operation is performed before automatic operation. By returning to the reference point, a fixed point becomes the machine reference point in the following manner.

A. When the return reference point key on the operation panel is pressed, the return reference point mode signal is turned on.

B.The turret is moved to the reference point position for each axis using the axis move switch.

C.When the reference point limit switch is triggered by the block, the deceleration signal turns on, the turret decelerates, and the turret moves to the machine reference point at the return to reference point speed.

D. When the reference point limit switch is released from the block, the turret moves continuously until the encoder sends the first grid signal. (This is the electronic reference point.) The turret continues to move from this point by the reference point offset amount. This point is saved as the machine reference point and, at the same time, the Return to Reference Point indicator is illuminated.

E. The grid signal is always on at a fixed point unless there is no change in relative position between the encoder input axis and the screw. The reference point offset is a fixed value set via the NC parameter. In this way, the machine reference point is accurately established.

Since the machine reference point is the datum of the machine coordinate system, it is important to return to the reference point.

When the machine is powered off, the record of the machine reference point is lost. Therefore, when the power is turned on, the first thing you must do is to return to the machine reference point.

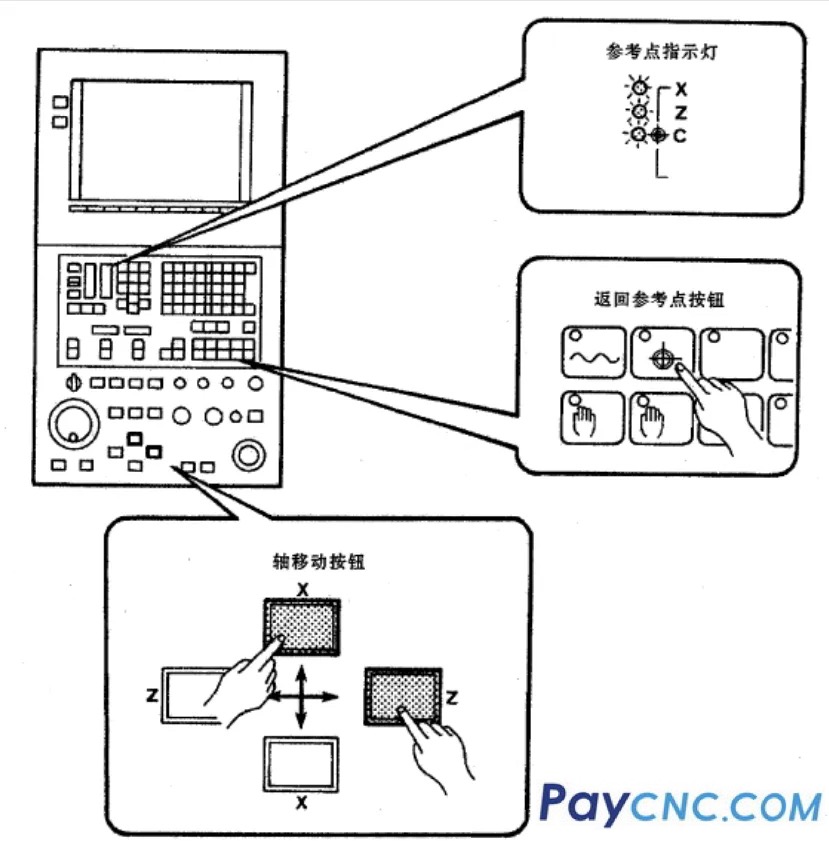

1. Press the reference point return button (HOME).

2. Press the Axis Move button so that the turret is at least 30mm (1.18in.) or more away from the reference point in the negative direction.

-When the reference point block is detected during axis travel, the direction of axis travel changes to the direction of returning to the reference point, and the travel speed changes to “return to reference point speed”.

For example, if the X-axis negative travel button is pressed near the X-axis reference point, when a reference point block is detected, the direction of axis travel becomes positive.

3. Keep a positive axis movement button pressed.

-When this button is released, the movement stops.

-When a reference point stopper is detected, the travel speed changes to the reference point return speed, at which point travel does not stop even if this button is released.

4. When the reference point return indicator (“X” or “Z”) lights up, release the pressed button. |