The hot summer is here, and the temperature in some workshops is also rising, so the precision equipment in the workshops began to have problems, the processing accuracy became unstable, and sometimes it went bad. Some machine tools failed many times and went on strike from time to time. Have these situations occurred in your factory?

When these problems occur in factories, we should analyze the root causes and solve the problems from the root causes. The more sophisticated the equipment, the stricter the requirements for the ambient temperature used, which requires the attention of factory managers.

01

Unstable accuracy

For high-precision machining, the temperature problem must not be ignored, because the temperature difference is the enemy of accuracy. Specifically, materials will expand with heat and contract with cold. The steel we use expands linearly to a length of 12μm per meter when the temperature changes by 1°C. This is the fact that every machine in every corner of the world is unchanged.

If we don't care about the important issue of temperature, how do we discuss accuracy? Most of the machine components are steel and cast iron, which will change shape and length according to the room temperature and the heat generated by the machine itself!

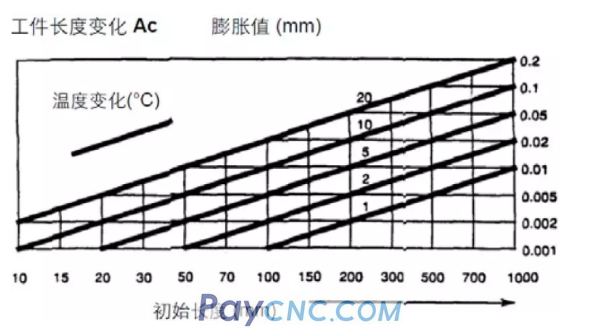

The expansion coefficient of steel is shown in the figure below:

For example:

Workpiece length: 200 mm

Temperature change: 10℃

Expansion value: 0. 02 mm

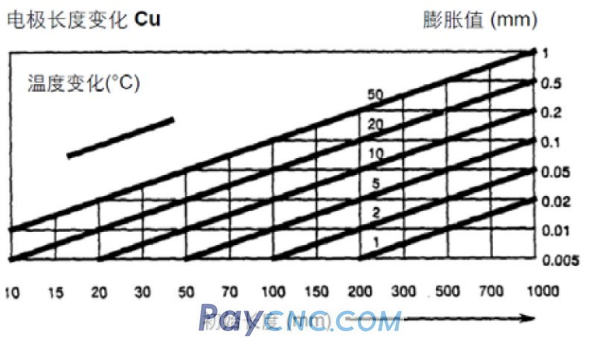

The coefficient of expansion of copper is shown in the figure below:

For example:

Electrode length: 200 mm

Temperature change: 10℃

Expansion value: 0.05 mm

In factories without precision machining experience, when doing precision machining, they often attribute unstable accuracy to equipment accuracy problems. For factories with precision machining experience, they all know that this is the most basic common sense, and they will attach great importance to the environmental temperature and the heat balance of the machine tool. They know very well that even high-precision machine tools can only obtain stable machining accuracy under a stable temperature environment and thermal equilibrium.

For high-precision machining of less than 3μm, the temperature must be controlled at a constant 20°C, with fluctuations less than 0.5°C/hour, and the air conditioning system maintains a constant temperature difference of ±1°C throughout the day. If the accuracy requirements are not so high, the control can be relatively broad, but the manager must have the concept of the effect of temperature on accuracy.

02

Malfunction

Some mold factories do not have air conditioners installed in the workshops. After the summer, the temperature in the workshop even exceeds 40℃, and some good CNC machine tools will definitely go on strike. In the high temperature environment, some mold factories try to remove various temperature alarms of the machine in order to allow the machine to continue processing, thinking that they are smart enough to make the machine work obedient. As everyone knows, hidden dangers are arising!

(1) Avoid machine failure or damage caused by condensation

For machine tools that use working fluid, such as machining centers, slow wire machine tools, and mirror discharge machines, when the ambient temperature is too high, the temperature of the working fluid will be higher, and once the temperature of the working fluid is too high, the machine will strike.

These machine tools are generally equipped with refrigerators. Some factories directly set the liquid temperature to 20°C, thinking that it is enough to lower the liquid temperature. At this time, the situation is that the ambient temperature is 40°C and the working fluid temperature is 20°C.

Think about it for a moment. The temperature difference between the working fluid and the environment is very large. If the fluid temperature is low and the ambient temperature is high, will there be a large amount of condensate in the part with the working fluid? You can go check it out! Just because of your stupid operation of setting the temperature, the guide screw of the machine tool is sweating. Over time will inevitably lead to severe rusting of parts; the circuit board of some machine tools is also sweating, and the consequences will be Don't mention it? In addition, the condensed water will be mixed into the working fluid. See how much water there is in your working fluid!

You may ask, what is the refrigerator used for? This requires a correct understanding: During the processing, the temperature of the working fluid must be higher than the ambient temperature. The purpose of using the refrigerator is to ensure that the temperature of the working fluid is consistent with the ambient temperature. Therefore, the correct setting method is to set the liquid temperature to the same "room temperature adjustment" as the environment. An important prerequisite here is to ensure a suitable ambient temperature.

The factory should install an air conditioning system to maintain a proper temperature, especially for precision numerical control equipment, which is the most basic requirement. Otherwise, there will be frequent failures and unstable processing quality. This kind of unwillingness to pay is definitely not worth the gain.

(2) Do a good job in the prevention of numerical control equipment

Of course, for ordinary numerical control equipment or non-precision processing, many factories cannot achieve a constant temperature environment, but the factory must do a good job of preventing numerical control equipment to ensure that the numerical control equipment can operate normally.

1) The air conditioner of the distribution box can work normally.

2) The door of the distribution box is tightly sealed. Some units simply open the distribution box to dissipate heat. This is a very dangerous thing. Outside dust entering the electric box will also cause damage to the components over time.

3) The power supply, drive circuit board, etc. with cooling fans can operate normally, and the cooling conditions are met.

4) Clean the ventilation trenches and heat sinks on the high-power circuit boards.

5) Maintenance personnel should conduct frequent inspections to eliminate hidden dangers in time.

In short, when the summer heat comes, I hope every factory can treat precision equipment well and remember to provide you with precision machine tools that continue to create value to escape the heat. Remind everyone that the remedy may not be too late. Please pay enough attention to it. Please forward it to the relevant personnel in the workshop. The value is unlimited!

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|