Macro program turning trapezoidal thread

N10 T1D1M3S300

N20 R1=0.2;---cut depth per cut

N30 R2=1;-Mark of current cutting times

N40 R3=0;--Total cutting times

N50 R4=3.5;-total depth of cut

N60 R5=30;-blank diameter

N70 R6=10;-Longitudinal starting point (z direction)

N80 R7=-30;---longitudinal end point (Z direction)

N90 R8=6;--lead

N100 R9=0;---start point offset angle

N110 R10=1.93;---groove bottom width

N120 R11=1;---tool width

N130 R2=1

N140 R3=R4/R1; calculate the total number of cuts

N150 AAA:; cycle mark

N160 G94F1000; G1 feed rate 1000mm per minute

N170 G0Z=R6+(R4-R1*R2)*TAN(19.8)+(R10-R11)/2; z-axis starting point offset right

N180 G1X=R5-2*R1*R2; X axis feed

N190 G33Z=R7K=R8 SF=R9; thread cutting

N200 STOPRE

N210 G0X=R5+2; X axis retracts (exit blank 2mm)

N220 Z=R6-(R4-R1*R2)* TAN(19.8)-(R10-R11)/2; Z axis starting point left offset

N230 G1X=R5-2*R1*R2; X axis feed

N240 G33Z=R7K=R8 SF=R9; thread cutting

N250 STOPRE

N260 G0X=R5+2; X axis retracts (exit blank 2mm)

N270 R2=R2+1; current cutting times plus 1

N280 IF R2>R3 GOTOF BBB; The cutting times are less than the total times and jump to AAA to continue execution

N290 GOTOB AAA

N300 BBB:

N310 G0Z=R6+(R10-R11)/2; z-axis starting point offset right

N320 G1X=R5-2*R4; X axis feed

N330 G33Z=R7K=R8 SF=R9; thread cutting

N340 STOPRE

N350 G0X=R5+2; After the cycle is completed, the X axis reaches the starting point

N360 Z=R6+2; Z axis returns to the starting point

N370 M30; End of subroutine

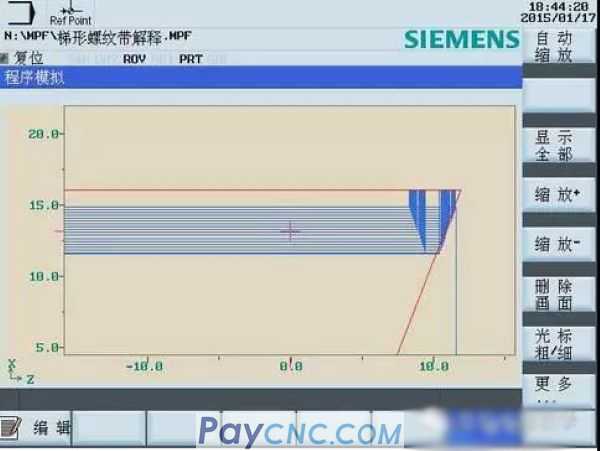

The simulation is as shown in the figure below, no question haha

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|