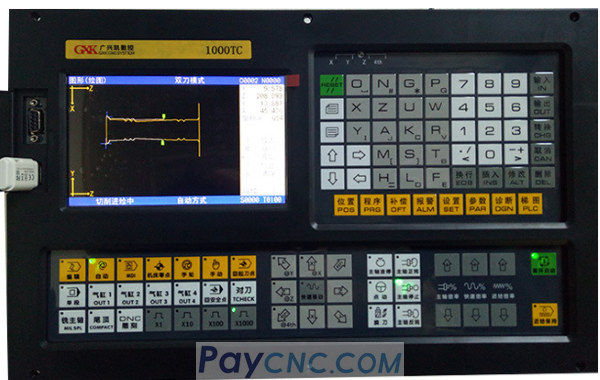

product manual:

GXK1000TC lathe CNC system is a single/double-axis CNC system based on GXK1000T lathe CNC system for software and hardware redesign. It uses 32-bit embedded CPu and ultra-large-scale programmable device FPGA, using real-time multi-task control technology and hardware plug-in. Complementary technology, realizes motion control with μm precision, high speed, high precision and high reliability with high integration, simple operation, complete programming instructions, unique acceleration and deceleration control and interpolation algorithm, significantly improving parts The processing efficiency, precision and surface quality have a high performance-price ratio and are the choice of economical CNC lathes.

* X, Z, Y, A four-axis control, Y-axis, A-axis axis name, axis type can be defined

* 1ms interpolation period, control accuracy 1μm, 0.1μm optional

*Speed 60m/min (speed 24m/min at 0.1μm)

*Adapting the servo spindle can realize automatic switching of asynchronous servo spindle turning and milling, and can also be electromagnetically switched.

* Built-in multi-PLC program for automatic loading and unloading.

* Support both woodworking car function and milling twist column and engraving function. The system software includes both perfect cutting processes.

* Support double-blade and single-blade one-time forming, support double-knife and single-knife repeated turning forming

* Support statement macro code programming, support macro call with parameters

* Breakpoint memory function, the electrical position will not be lost during processing

* Graphic display, real-time processing trajectory movement tracking display.

* Import of processing files supports manual editing of G commands, U disk G code files and dxf files for direct reading, and Chinese DBF file import.

* Control 4 step/servo motors at the same time, support 4-axis G code command

*External handheld box function

* Supports metric/imperial programming with automatic tool setting and tool life management

*Support Chinese and English display, selected by parameters

* With USB interface, support U disk file operation, system configuration and software upgrade

*Key file backup and restore, system parameter backup and restore function

*Support four-station electric tool holder function   |

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|