|

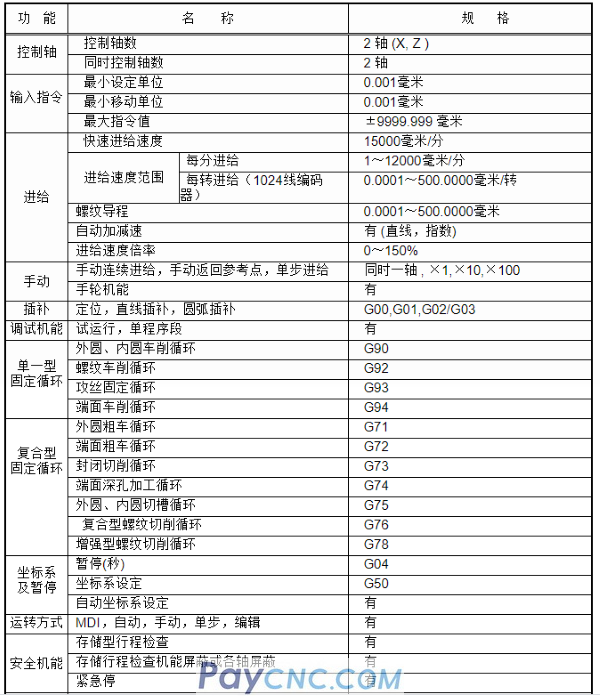

Controlled Axes

|

Number of axis controlled

|

2 axes (X, Z)

|

|

Number of axis controlled simultaneously

|

2 axes

|

|

Command

|

Least Command Unit

|

0.001 mm

|

|

Least Move Unit

|

0.001 mm

|

|

Maximum Command Value

|

±9999.999 mm

|

|

Feed

|

Traverse (Maximum)

|

15000 mm/min

|

|

Feed rate range

|

mm/min (Per-Minute Feed)

|

1~12000 mm/min

|

|

mm/r(Encoder of 1024 pulse/r is required) (Per-Revolution Feed)

|

0.0001~500.0000mm/r

|

|

Lead of Thread

|

0.0001~500.0000 mm

|

|

Automatic Acceleration/Deceleration

|

Provided(linear, exponential)

|

|

Feed Rate Override

|

0~150%

|

|

Manual

|

Manual Continuous Feed, Manual return To Reference Point, Step feed

|

One axis a time, ×1, ×10, ×100

|

|

Manual pulse generator

|

Provided

|

|

Interpolation

|

Positioning, linear/circular interpolation

|

G00, G01, G02/G03

|

|

Test

|

Dry run, Single Block

|

Provided

|

|

Canned cycle

|

Inner/outer diameter cutting cycle

|

G90

|

|

Thread cutting cycle

|

G92

|

|

Canned Tapping Cycle

|

G93

|

|

Facing cycle

|

G94

|

|

Multiple repetitive cycle

|

Outer Diameter Rough Turning Cycle

|

G71

|

|

Rough Facing Cycle

|

G72

|

|

Canned Turning Cycle

|

G73

|

|

End Peck drilling Cycle

|

G74

|

|

External/Internal Slotting Cycle

|

G75

|

|

Multiple Thread Cutting Cycle

|

G76

|

|

Enhanced Thread Cutting Cycle

|

G78

|

|

Coordinate system and Dwell

|

Dwell(sec)

|

G04

|

|

Coordinate system setting

|

G50

|

|

Auto coordinate system setting

|

Provided

|

|

Run mode

|

MDI, Auto, Jog, Step, Edit

|

Provided

|

|

Safety

|

Stored Stroke Check

|

Provided

|

|

Stored Stroke Check Disabled/ Every Axis Disabled

|

Provided

|

|

Emergency Stop

|

Provided

|

|

Program storage and edit

|

Program Storage Capacity, Stored Program Number

|

32kB, 63

|

|

Program Edit

|

Insert, modify, delete, copy

|

|

Program No. , Sequence No., Address, Word Search

|

Provided

|

|

Decimal Point Programming, Optional Block Skip

|

Provided

|

|

Flash Memory

|

Provided (six partitions)

|

|

Display

|

LCD

|

800×480, 7 inch color LCD

|

|

Position, Program, Tool Compensation, Alarm, Test, Diagnosis, Parameter

|

Provided

|

|

Graph, Work-piece Counts

|

Provided

|

|

M, S, T function

|

I/O: 20/16 points

|

Input: (panel: 4 points, machine tool: 16 points)

|

|

Miscellaneous Function

|

2-digit M code

|

|

Spindle Function

|

2-digit S code (gears) or

4-digit S code (analog spindle)

|

|

Analogue Spindle(S4 bit), Constant Surface speed Cutting

|

Provided (8-bit D/A output)

|

|

Tool Function

|

T01~T08

|

|

Tool Rest Signal Timing Scan Check function

|

Provided

|

|

Compensation function

|

Tool Compensation Memory

|

±6 bit, 8 groups

|

|

Tool Compensation Count Mode Input

|

Provided

|

|

Tool Compensation Measurement Mode Input

|

Provided

|

|

Tool Tip (Nose) Radius Compensation (Tool Compensation C)

|

Provided

|

|

Backlash Compensation

|

Provided

|

|

Switch

|

Program Switch, Parameter Switch

|

Provided

|

|

Communication

|

RS232 communication

|

Provided

|

|

U Disk Communication

|

Provided

|

|

Other functions

|

Circular Radius R Setting

|

Provided

|

|

Electronic Gear Ratio

|

Provided

|

|

Back Tool Rest Selection

|

Provided

|

|

Power Off Work-Piece Coordinate Recall

|

Provided

|

|

Rotary Axis Setting

|

Provided

|

|

Clock

|

Provided

|

|

Tailstock function

|

Provided

|

|

Auto lubricating function

|

Provided

|

|

Power Off Work-Piece Coordinate Recall

|

Provided

|

|

Suited driver for CNC system

|

KND step motor driver

|

|

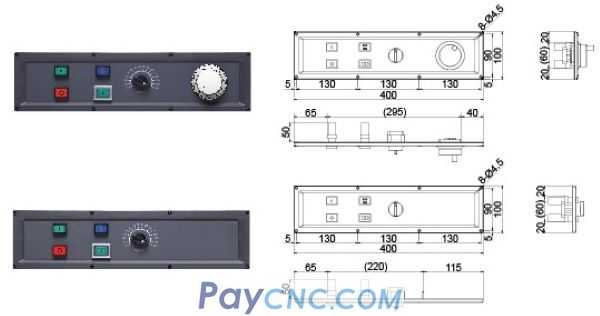

The Add-on Panel of CNC System for Lathes

|

Optional

|