The KY980TB/KY980Tc lathe CNC system is a dual/three-axis CNC system based on the KY000T lathe CNC system for software and hardware re-optimization. The system adopts 32-bit high-performance CPU and ultra-large-scale programmable device FPGA. Real-time control and hardware interpolation technology ensure the high efficiency of the system with μm-level precision. The editable PLC makes the logic control function more flexible and powerful. The KY980TB system can control 3 feed axes, 1 analog spindle, 1ms high-speed interpolation, and 0.1μm control accuracy, which significantly improves the efficiency, accuracy and surface quality of parts processing.

Functional characteristics

· Number of control axes: 3 feed axes, one analog spindle;

· Number of linkage axes: straight line 3 axes; arc 2 axes;

· Adapted servo spindle can realize spindle continuous positioning, rigid tapping and rigid thread processing

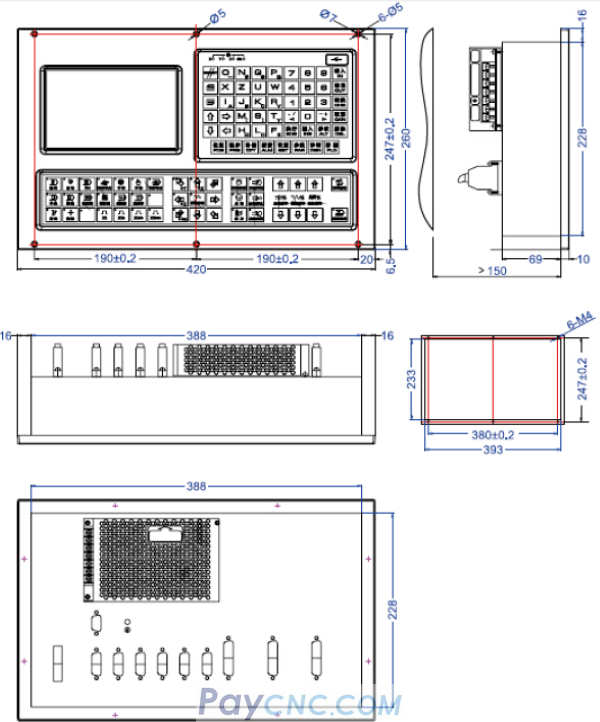

· 8.0-inch widescreen LCD with a resolution of 800×480

· Adopt 32-bit high-performance CPU and ultra-large-scale programmable device FPGA

· 56M user storage space

· Real-time all-round self-diagnosis function, real-time display of various statuses

· Feed per minute, feed per revolution

· Metric and imperial input methods

· Machine tool return to reference point

· Fast override: F0, 25%, 50%, 100%, four levels of real-time adjustment

· Feedrate override: 0~150%, total 16 levels, real-time adjustment

· 1 spindle encoder feedback, the number of spindle encoder lines can be set (100p/r~5000p/r)

· Transmission ratio between encoder and main shaft: (1~255): (1~255)

· Spindle speed: can be given by S code or PLC signal, the speed range is 0r/min~9999r/min

· Spindle override: 50%~120% total 8 levels real-time adjustment

· Spindle constant line speed control

· Interpolation methods: linear interpolation, circular interpolation (supporting three-point circular interpolation), thread interpolation, rigid tapping

· Automatic chamfering function

· ISO code, support sentence type macro code programming, support relative coordinate, absolute coordinate and mixed coordinate programming

· Program call: support macro call with parameters, 4-level subroutine nesting

· Independent backlash compensation for each axis, memory type pitch error compensation* Tool length compensation

· Tool nose radius compensation (C type), tool wear compensation, tool life management

· Tool setting methods: fixed-point tool setting, trial cutting tool setting, tool setting back to reference point, automatic tool setting

· Tool offset execution mode: modify coordinate mode, tool movement mode

· Independent setting of maximum speed and acceleration/deceleration for each axis

· Spindle constant line speed control

· Thread function

· Flexible tapping

· Emergency stop, hardware travel limit, software travel check

· Chinese and English page switching

· Display real-time time, number of processed pieces, processing time and other information

· Various interpolation command functions and M, S, T functions, etc.

· Data backup and recovery, upgrade function

Special advantage

1. Speed advantage

· The highest fast moving speed can reach 60m/min

· Maximum cutting speed can reach 30m/min

· Cutting feed: front acceleration/deceleration linear type, front acceleration/deceleration S type, rear acceleration/deceleration linear type, rear acceleration/deceleration exponential type

· Rapid traverse: front acceleration/deceleration linear type, front acceleration/deceleration S type, rear acceleration/deceleration linear type, rear acceleration/deceleration exponential type

· Thread cutting: linear and exponential

· The start speed, end speed and acceleration/deceleration time of acceleration/deceleration are set by parameters

· Program preprocessing can realize smooth and seamless connection between program segments; smooth transition can be selected between program segments

2. Precision advantages

· Lead screw pitch compensation and memory type pitch error compensation to maximize machining accuracy

· 1ms high-speed interpolation, control accuracy 1μm, 0.1μm optional, significantly improve the efficiency, accuracy and surface quality of parts processing.

3. Interface advantages

· Users can edit I/0 logic control by themselves, 18 input/18 output, input signal can realize high and low level online switching

· PLC program communication download

· USB removable U disk copy interface, can realize U disk DNC function, realize external mass storage, can realize system upgrade, parameter, ladder diagram copy/restore

· RS232: Two-way transmission of parts programs, parameters and other files, supporting serial port upgrade of PLC programs and system software

· Can be equipped with external handwheel or panel handwheel

· Spindle frequency conversion control, feed axis pulse control

4. Operational advantages

· Full-screen editing system, online modification of tool offsets, parameters and other operations

· Two-dimensional tool path display, and graphics can be arbitrarily zoomed in, zoomed out, and translated, and the direction of the graphics coordinate system can be changed

· Multi-level password protection can be realized, such as program, parameter, ladder diagram protection, convenient on-site management

· Compatible with domestic and foreign mainstream CNC system instruction codes

· Real-time adjustment of spindle, feed and fast speed

· Start processing at any block, start processing at any tool number

· During processing, single-stage and continuous switching at will

· Support handwheel trial cutting function

· Support program/program segment/word retrieval, modification, deletion, copy, paste

· View the alarm record, which is convenient for finding program errors or machine failures

· Support help function, you can view code meaning and operation guide

· Support online editing PLC

· Support multiple PLC programs (up to 20), the current running PLC program can be selected

· Chinese and English interface switching

· User-defined I/O

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|