K1000MII&K1000M4II are superior CNC systems for milling machine and machine center, which adopt with high performance 32-bit microprocessor, new structure design and open PLC process.

They are employed with 8.4 inch color LCD display. They can control 3/4 feeding axes, 3/4 simultaneously controlled axes. They can be matched with KND or YASKAWA Digital AC servo driver. K1000MII&K1000M4II are suitable for CNC Milling Machine and Machine Center.

l Adopt 32-bits powerful CPU to achieve high-speed, high-precision control. The maximum speed reaches up to 30 m/min

l 7.5/8.4 inch TFT LCD with the resolution of 640×480.

l Six layer main board applying custom-build FPGA, high integration technology, perfect structure design ensures that the system has high reliability and high anti-interface capability.

l Support the open-style PLC function to meet the secondary development of the machine tool builder.

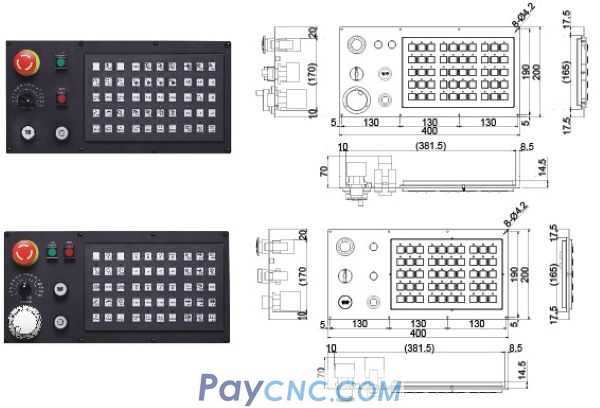

l Two types of machine control panels including the standard panel with film-buttons and one with pushed buttons are available. On the later one the functions of the 50 pushed buttons and 50 lamps are able to defined by customs.

l Remote I/O modules based on CAN bus can be use to extend the number of I/O points up to 512/512.

l Chinese operation interface and full help information make the operation more conveniently.

l Perfect self-diagnosis function. Display the internal and external states in real time and alarms will be issued timely when some abnormity happen.

l Powerful instruction execution ability to achieve the high-speed, small-line-section machining

l High-speed DNC machining are available based on the transmit rate reaches up to 115200 bps and large program buffer space.

l 640 kB internal program memory space. U-disk port can be use to extend the space of program and to perform DNC machining.

l Rich NC functions: macro program B, rigid tapping, local coordinate system, coordinate system rotation, coordinate scaling, polar coordinate system, etc.

|

Function

|

Specification

|

Function

|

Specification

|

|

Model

|

K1000MII

|

K1000M4II

|

Program

|

Absolute / incremental mixture programming. Decimal point function in programming

|

|

Axis

|

X、Y、Z

|

X、Y、Z、4

|

Workpiece coordinates

|

G54~G59

|

|

Interpolation axis number

|

3

|

4

|

Subprogram calling function

|

Provided

|

|

Interpolation

|

Linear interpolation, arc interpolation, helical line interpolation, polar coordinate interpolation(optional)

|

English and metric unit exchanging

|

Provided

|

|

Least setting unit

|

0.001 mm or 0.0001 mm

|

Communication

|

RS232

|

|

Largest command dimension

|

±99999.999 mm

|

|

Maximum rapid traverse rate

|

30000 mm/min

|

Remote control

|

Transmitting PLC program, machining program, parameters, etc.

|

|

Maximum feed rate

|

15000.000 mm/min

30000 mm/min (optional)

|

U-disk interface

|

Provided

|

|

Feed rate override

|

JOG/AUTO: 0~150%

|

Macro program

|

Macro A or Macro B

|

|

Emergency stop and stroke limit

|

Standard PLC program supports three emergency stop signals. Both stored stroke limit and hardware stroke limit are available.

|

|

Program memory space and electric disk

|

640 kB, 128, 3

640 kB, 512, 3 (optional)

|

Alarm

|

PS alarm, Servo driver alarm, Exceed stroke limitation alarm, System error alarm, External alarm

|

|

Interface

|

7.5/8.4 inch TFT LCD

|

|

Revolution: 640×480

|

Acceleration/deceleration control

|

Linear and exponential type control

|

|

Additional interface

|

Additional panel, Independent operation box

|

Reference position return

|

Provided

|

|

Display

|

Coordinate value, machining time, workpiece count, date, feed rate, etc.

|

Electrical gear ratio

|

1~127, 1~127

|

|

Graph function

|

Tool path displaying

|

Machine control

|

Machine lock

Feed hold

Block skip

|

|

PLC

|

Open-style PLC

|

Feed control

|

AUTO, JOG, STEP, HANDLE

|

|

Tool compensation

|

Tool length compensation

Tool tip radius compensation

|

DI/DO

|

DI: 40 DO: 24

DI/DO points can be extended by CAN bus

|

|

Driver

|

Digit AC servo driver

|

|

Backlash compensation

Pitch-error compensation

|

Provided

|

Tool length offset value

|

32

|

|

Spindle function

|

Gear shifting control

Analog spindle control

Rigid tapping control

|

Tool control

|

Controlled by PLC program

|

|

Miscellaneous functions

|

Control the spindle rotation, coolant, lubrication, in JOG /MDI /AUTO mode

|

Cycle for drilling, tapping and boring

|

Provided

|

|

Plane selection

|

G17/G18/G19

|

|

DNC machining

|

With RS232 or U-disk

|

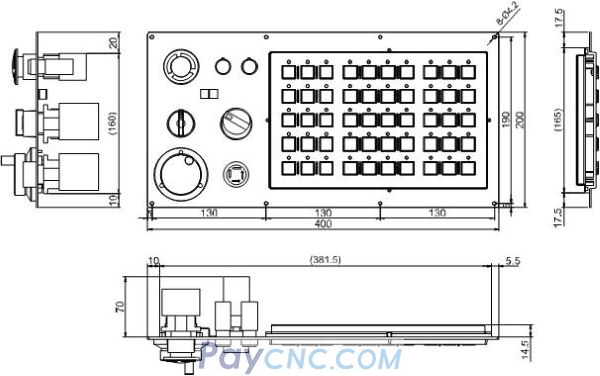

Machine control panel (pushed button) and additional panel :

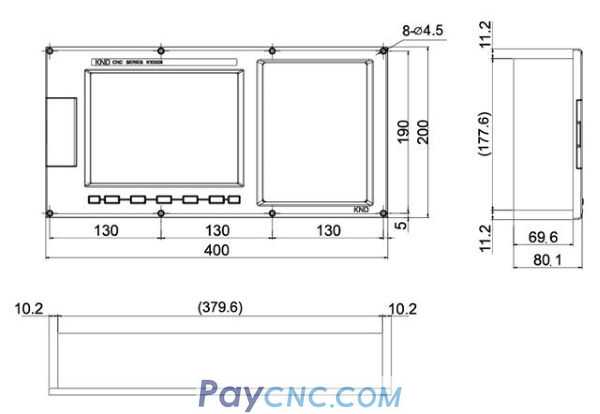

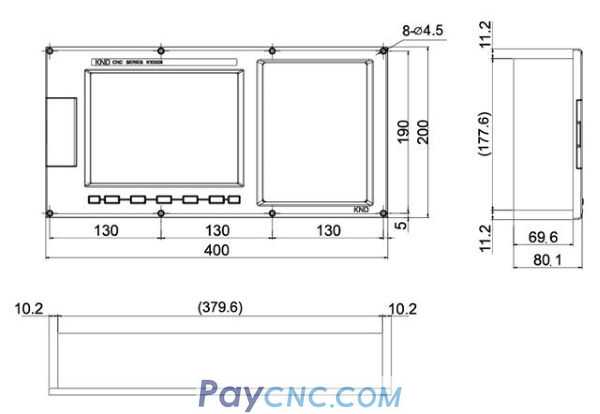

Machine control panel (film-button) and additional panel:

Remote IO module:

|