K1000MIV&K

l Apply 32-bits powerful CPU to achieve high-speed, high-precision control. The maximum speed reaches up to l 10.4 inch TFT LCD with the resolution of 640×480. l Six layer main board applying SMT, custom-build FPGA, high integration technology, perfect structure design ensures that the system has high reliability and high anti-interface capability. l Support the open-style PLC function to meet the secondary development of the machine tool builder. l Two types of machine control panels including the standard panel with film-buttons and one with pushed buttons are available. On the later one the functions of the 50 pushed buttons and 50 lamps are able to defined by customs. l Remote I/O modules based on CAN bus can be use to extend the number of I/O points up to 512/512. l Chinese operation interface and full help information make the operation more conveniently. l Perfect self-diagnosis function. Display the internal and external states in real time and alarms will be issued timely when some abnormity happens. l Powerful instruction execution ability to achieve the high-speed, small-line-section machining l High-speed DNC machining are available based on the transmit rate reaches up to 115200 bps and large program buffer space. l 640 kB internal program memory space. U-disk port can be use to extend the space of program and to perform DNC machining. l Rich NC functions: macro program B, rigid tapping, local coordinate system, coordinate system rotation, coordinate scaling, polar coordinate system, etc.

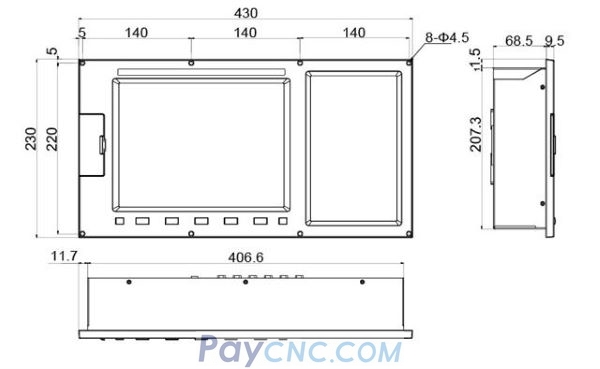

Horizontal Layout (H) :

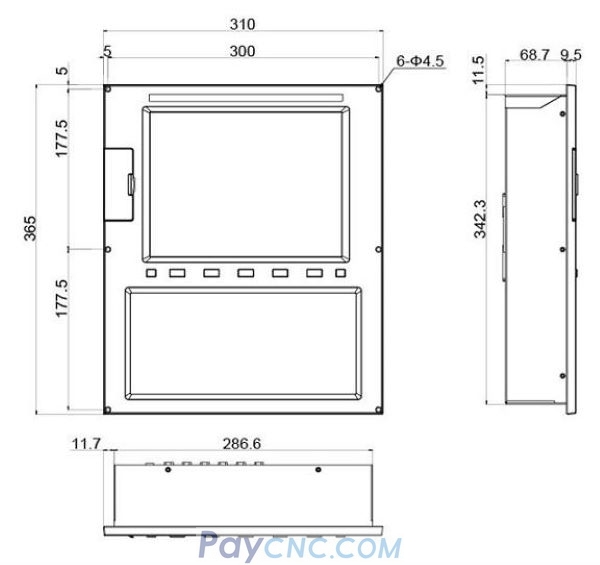

Vertical Layout(V):

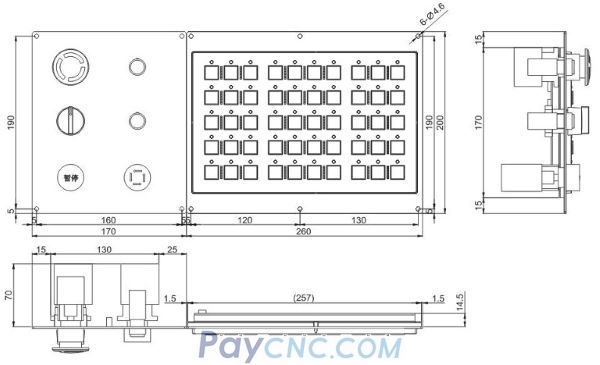

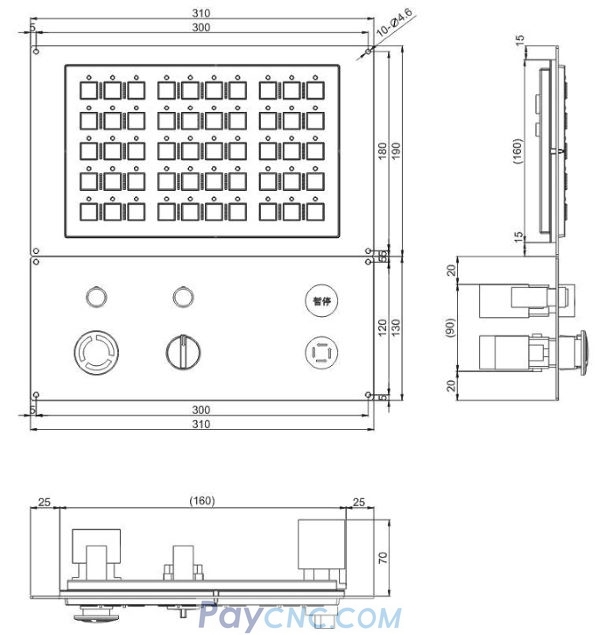

Horizontal Layout (H) Machine control panel (pushed button) and additional panel :

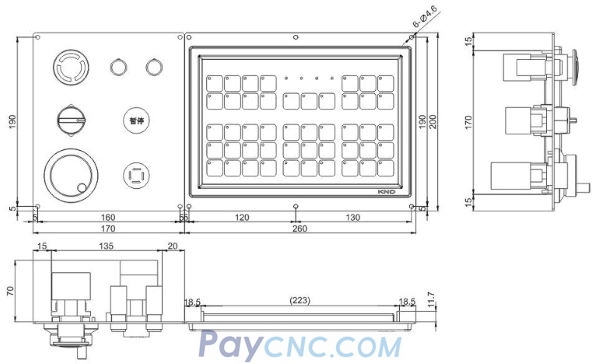

Machine control panel (film-button) and additional panel :

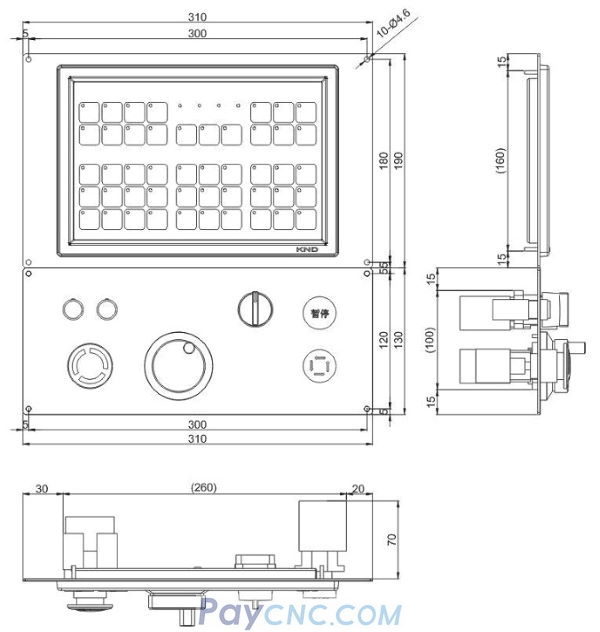

Vertical Layout(V) Machine control panel (pushed button) and additional panel:

Machine control panel (film-button) and additional panel:  Remote IO module:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|