1000TII from CNCmakers Limited, is a superior turning machine CNC system with high performance 32-bit microprocessor, new structure design and open PLC process. It is employed with 8.4 inch color LCD display. It can control 4 feeding axes, 4 simultaneously controlled axes. It can be matched with SD or YASKAWA Digital AC servo driver. 1000TII is suitable for full function CNC Turning Machine.

l Adopt 32-bits powerful CPU to achieve high-speed, high-precision control. The maximum speed reaches up to l 7.5/8.4 inch TFT LCD with the resolution of 640×480. l Six layer main board applying custom-build FPGA, high integration technology, perfect structure design ensures that the system has high reliability and high anti-interface capability. l Support the open-style PLC function to meet the secondary development of the machine tool builder. l Two types of machine control panels including the standard panel with film-buttons and one with pushed buttons are available. On the later one the functions of the 50 pushed buttons and 50 lamps are able to defined by customs. l Remote I/O modules based on CAN bus can be use to extend the number of I/O points up to 512/512. l English operation interface and full help information make the operation more conveniently. l Perfect self-diagnosis function. Display the internal and external states in real time and alarms will be issued timely when some abnormity happen. l Powerful instruction execution ability to achieve the high-speed, small-line-section machining l 640 kB internal program memory space. U-disk port can be use to extend the space of program and to perform DNC machining. l Rich NC functions: macro program B, rigid tapping, local coordinate system, coordinate system rotation, coordinate scaling, polar coordinate system, etc.

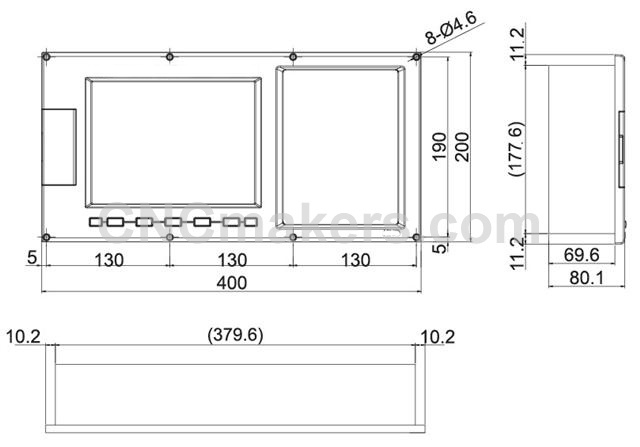

Function Specification Function Specification NC axis number 2 axes (X, Z) English and metric unit exchanging Provided Interpolation axis number 2 axes (X, Z) Communication RS232 Interpolation Linear interpolation arc interpolation Least setting unit 0.0001 inch Remote control Transmitting PLC program, machining program, parameters, etc. Largest command dimension ± U-disk interface Provided Maximum rapid traverse rate Macro program Provided Maximum feed rate Emergency stop and stroke limit Standard PLC program supports three emergency stop signals. Both stored stroke limit and hardware stroke limit are available. Feed rate override JOG/AUTO: 0~150% Alarm PS alarm, Servo driver alarm, Exceed stroke limitation alarm, System error alarm, External alarm Program memory space and electric disk 640 kB/128/3 640 kB/512/3(optional) Acceleration/deceleration control Linear and exponential type control Interface 7.5/8.4 inch TFT LCD Reference position return Provided Revolution: 640×480 Electrical gear ratio 1~127, 1~127 Additional interface Additional panel, Independent operation box Machine control Machine lock Feed hold Block skip Display Coordinate value, machining time, workpiece count, date, feed rate, etc. Feed control AUTO, JOG, STEP, HANDLE Graphic function Tool path displaying DI/DO DI: 40 DO: 24 DI/DO points can be extended by CAN bus PLC Open-style PLC Driver Digit AC servo driver Tool compensation Tool length compensation Tool tip radius compensation Measuring function Provided Backlash compensation Pitch-error compensation Provided Canned cycle Provided Spindle function Gear shifting control Analog spindle control Rigid tapping control Thread cutting Straight thread, cone thread, end-face thread, variable-pitch thread Miscellaneous functions Control the spindle rotation, coolant, lubrication, in JOG /MDI /AUTO mode Diameter/Radius programming Provided Feed per minute Feed per revolution Provided Program Absolute / incremental mixture programming. Decimal point function in programming Constant surface speed control Provided Workpiece coordinates G54~G59 Tool length compensation 16 Subprogram calling function Provided Tool control Controlled by PLC 1000TII Turning CNC Control Dimension  Machine control panel (pushed button) and additional panel:

Machine control panel (film-button) and additional panel:

Remote IO module:

|

|

| Products Catalogue | Home | About Us | Retrofit | Download | News | Tech Support | Contact Us | |

|

|

|